Outdoor machine of air conditioner

A technology for outdoor units and air conditioners, applied in the field of outdoor units, can solve problems such as top panel deformation, achieve the effects of increasing productivity, preventing deformation, and improving installation workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

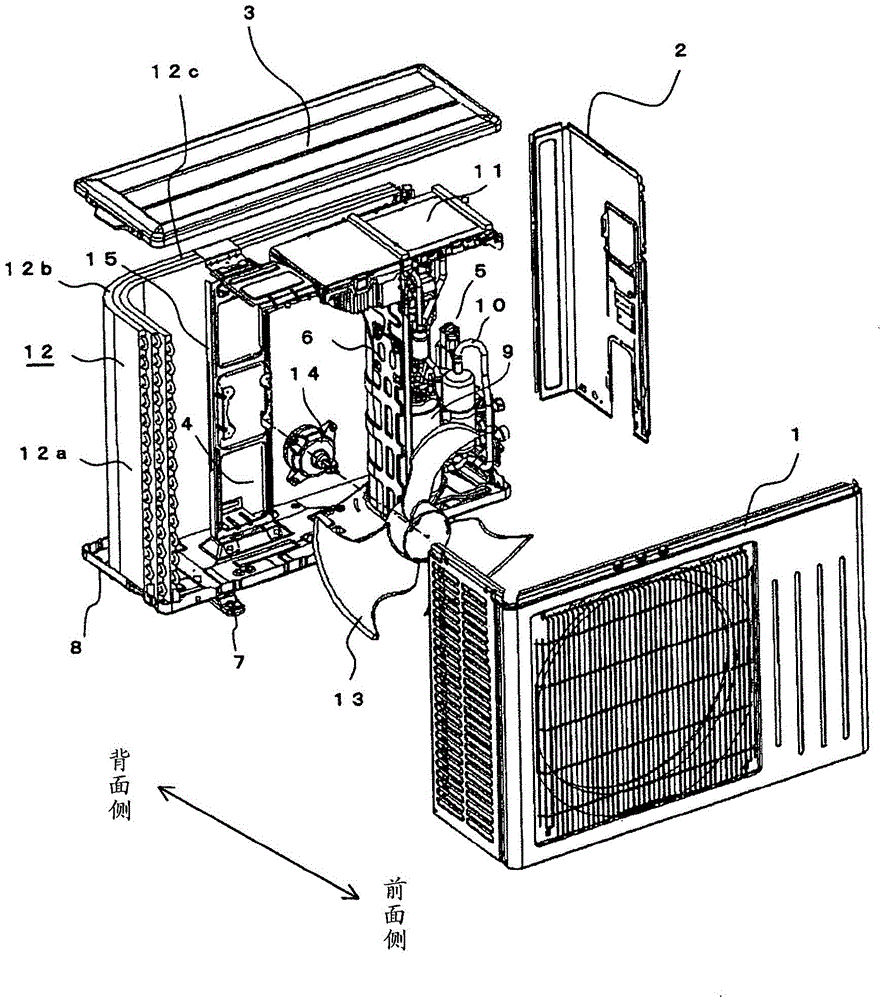

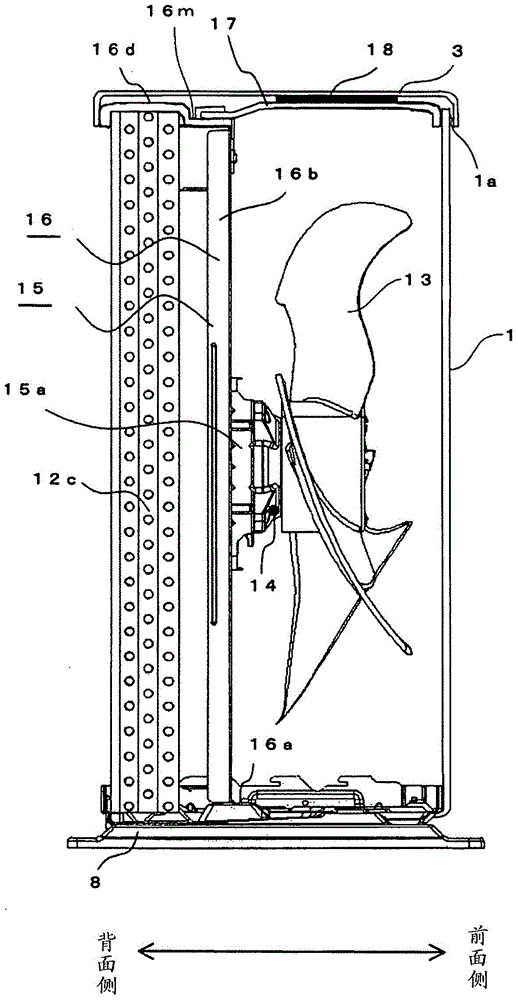

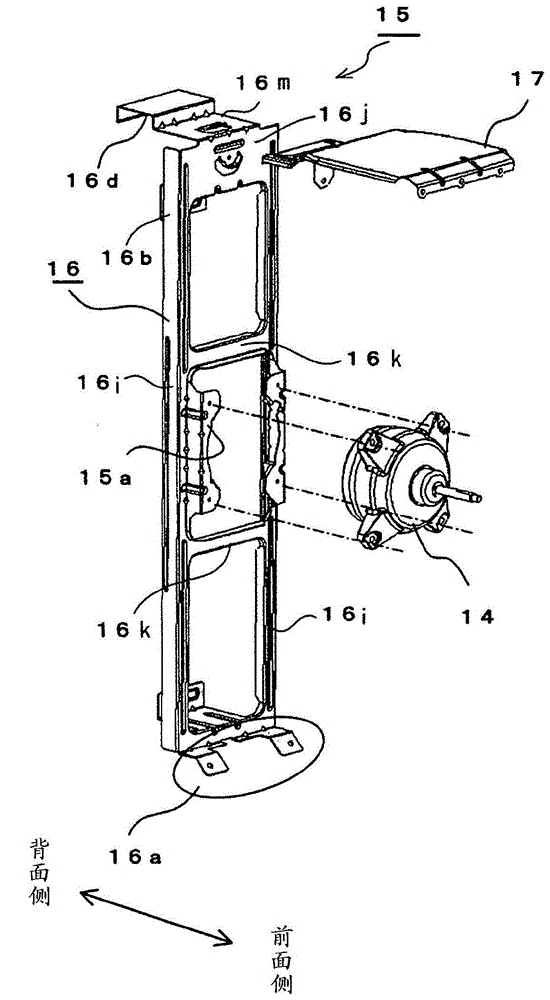

[0035] Hereinafter, the outdoor unit of the air conditioner according to Embodiment 1 of the present invention will be described in detail using the drawings.

[0036] figure 1 It is an exploded perspective view showing an outdoor unit (hereinafter, sometimes simply referred to as an outdoor unit) of the air conditioner according to Embodiment 1 of the present invention. like figure 1 As shown, a plurality of panels, such as a front panel 1 , a side panel 2 , a top panel 3 , and a bottom panel 8 constitute a roughly rectangular parallelepiped frame of the outdoor unit. The plurality of panels are all made of metal plates. The front panel 1 is substantially L-shaped in horizontal cross-section, and constitutes the front portion of the housing, and also constitutes the side surface portion on the opposite side of the side panel 2 . The top panel 3 constitutes the top surface of the outdoor unit frame. Furthermore, a heat exchanger (described later) is arranged on the back ...

Embodiment approach 2

[0070] In Embodiment 1, when the top panel 17 is slid, the fan motor support plate side fitting portion 16c is formed by cutting and rising in an L-shape in cross section, and the rear side of the fitting portion on the top panel horizontal surface 17m is The end surface 17a and the top panel side fitting part 17b are slid to the lower side of the L-shaped support horizontal surface 16m, and movement in the up-down direction is restricted. In Embodiment 2 of the present invention, another configuration example of the fitting portion will be described. When the top plate 17 is slid, the movement in the vertical direction of the top plate 17 is restricted, and the top plate 17 is positioned relative to the fan motor support plate 16. Align in the up and down direction.

[0071] Figure 8 It is an explanatory diagram showing the fitting portion of the fan motor support plate 16 and the top plate 17 according to Embodiment 2 of the present invention. Figure 8 (a) is a plan view...

Embodiment approach 3

[0080] In Embodiment 1, Figure 7 The shown guide portion 16f has a function of restricting the movement of the top panel 17 in the left-right direction W and positioning the top panel 17 when the operator slides the top panel 17 from the front side to the rear side with respect to the fan motor support plate 16, but is not limited to Figure 7 The structure of the guide portion 16f is shown. The function of the guide portion is to position the fan motor support plate 16 and the top plate 17 to face each other in the left-right direction W when the top plate 17 is slid. By positioning the fan motor support plate 16 and the top plate 17 in the left-right direction relative to each other by using the guide, the fan motor support plate side fitting portion 16c of the fan motor support plate 16 and the top plate side fitting portion 17b of the top plate 17, and The threaded holes 16e for fixing the top plate and the threaded holes 17e of the fan motor support plate are aligned in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com