Test specimen hydraulic bulging test method and device

A technology of hydraulic bulge and test method, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., which can solve the problems that the reliability of the test cannot be effectively guaranteed, and the real force of the sample cannot be accurately reflected, so as to achieve the The power situation is simple, the reliability is guaranteed, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

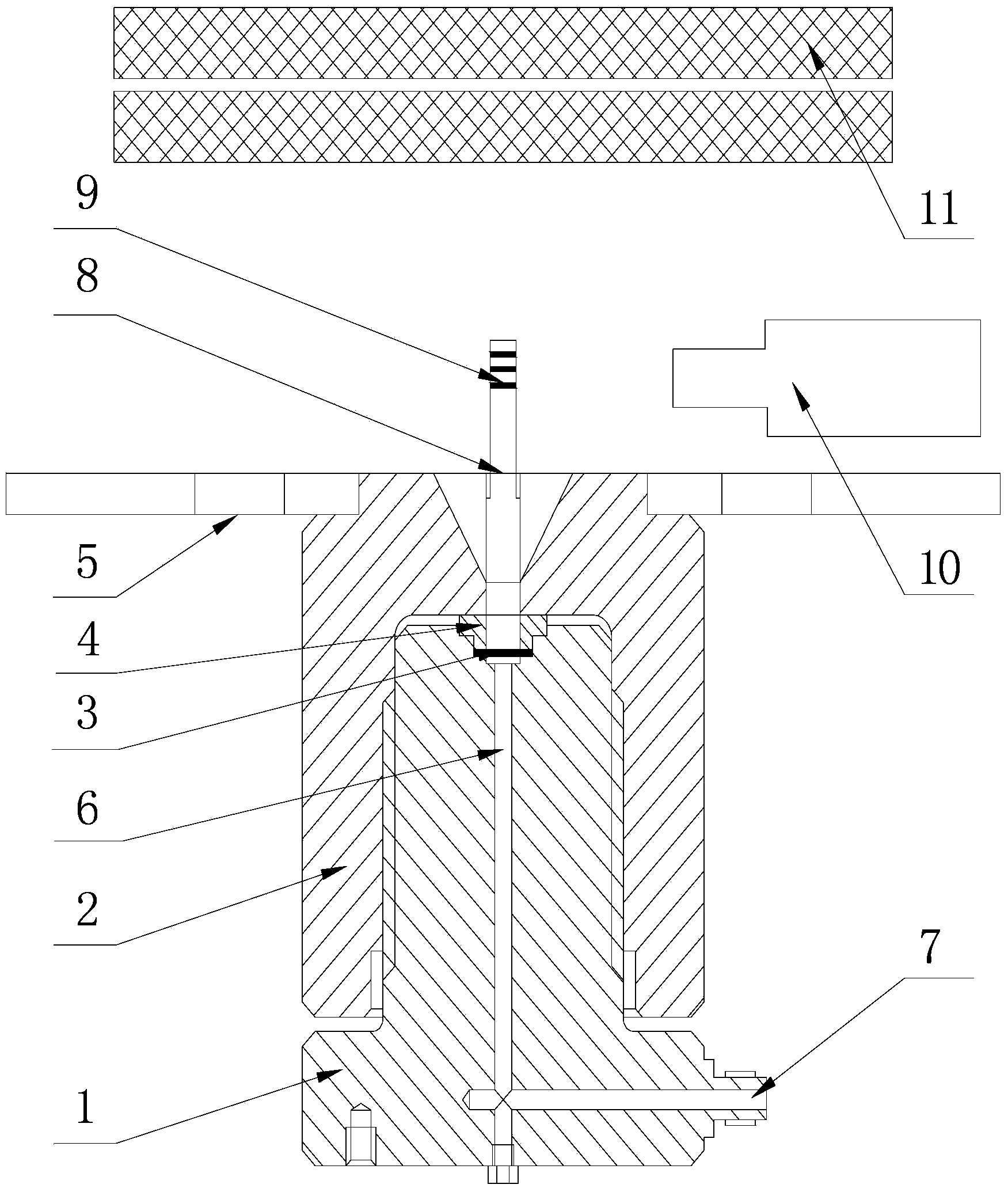

[0035] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

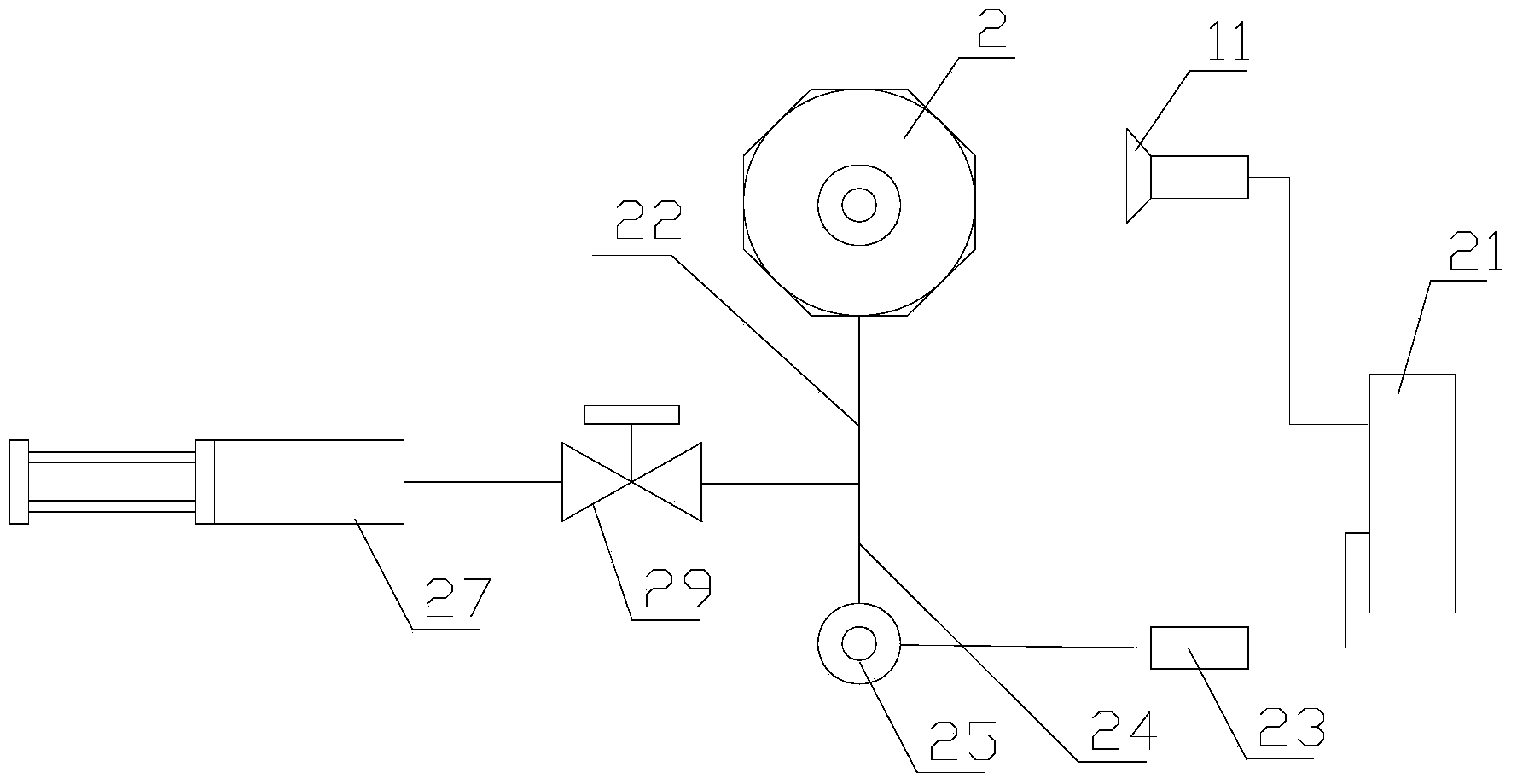

[0036] Such as figure 1 with figure 2 As shown, the present invention proposes a sample hydraulic swelling test device for clamping and testing sample 3, the sample 3 is, for example, in the shape of a disc, and the sample hydraulic swelling test device includes:

[0037] Base 1;

[0038] The hydraulic chamber 6 is arranged in the base 1;

[0039] A sample installation groove (not marked in the figure) is set on the base 1 and connected to the top of the hydraulic chamber 6 to accommodate the sample 3;

[0040] The gland 4 is set on the top of the sample installation groove and pressed against the sample 3 for pressing the edge of the sample 3; the gland is ring-shaped with a through hole in the middle for placing Displacement conducting part 8;

[0041] The clamping nut 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com