Liquid crystal display panel and manufacturing method of liquid crystal display panel

A liquid crystal panel, inner surface technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of TFT deterioration and rapid decline in display effect of the display panel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

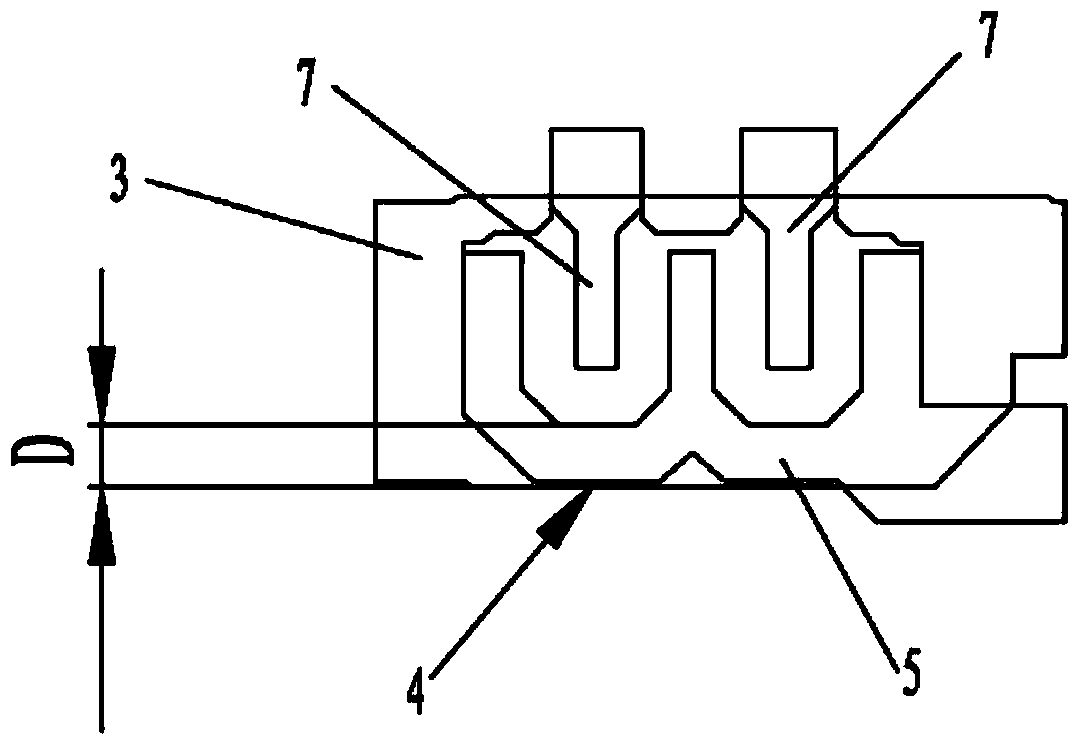

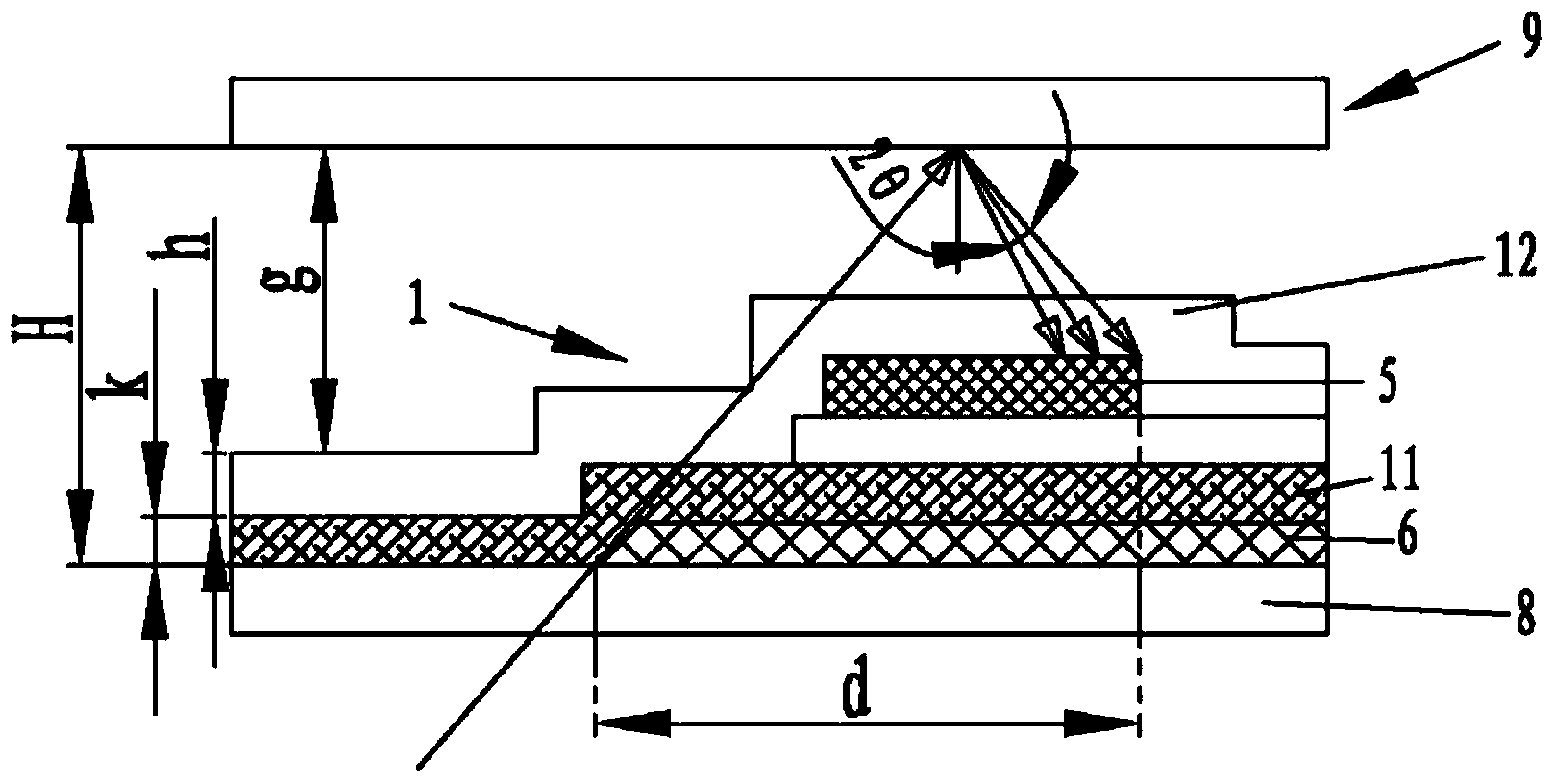

[0050] Such as figure 1 , figure 2 As shown, the embodiment of the liquid crystal panel of the present invention includes an array substrate 1 and a box-matching substrate 9 that is box-matched with the array substrate 1. A plurality of data lines (not shown in the figure) and a plurality of gate lines are provided on the array substrate 1 3. A plurality of data lines and a plurality of gate lines 3 intersect to define a plurality of pixel regions; the array substrate 1 also includes a plurality of TFTs, the TFTs include a source 5, a drain 7 and a gate 6, an area occupied by at least one TFT The opaque region containing the channel region 4 is included in, and the distance D between the boundary of the channel region 4 and the boundary of the opaque region in the direction parallel to the liquid crystal panel is greater than or equal to the set distance d.

[0051] In an embodiment of the liquid crystal panel of the present invention, the opaque area may be formed by opaque gat...

Embodiment 2

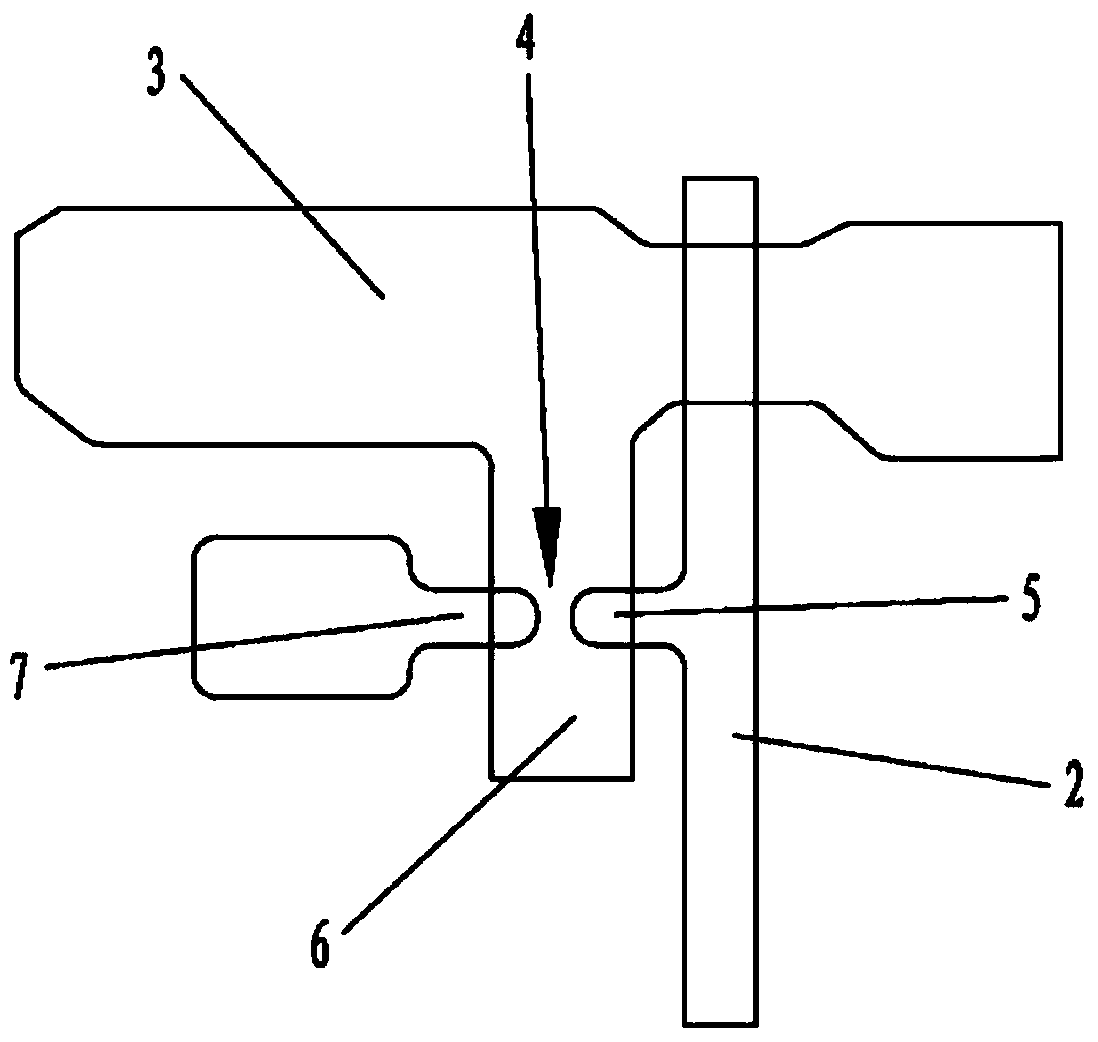

[0079] Such as image 3 , Figure 4 As shown, in the embodiment of the liquid crystal panel of the present invention, a plurality of data lines 2 are provided on the array substrate 1, the TFT includes a gate 6 connected to the gate line 3, and the projection of the channel region of the TFT is located at the gate 6 Within the region, the boundary of the opaque region includes the boundary of the source 5 on the side away from the channel region 4 and the boundary of the drain 7 on the side away from the channel region 4.

[0080] The width of the region composed of the source electrode 5, the drain electrode 7 and the channel region 4 is greater than the width of the gate electrode 6, and the channel region 4 is a long strip region (for example, the area formed between the source electrode and the drain electrode) image 3 Exemplarily shown as a long strip area in the up and down direction).

[0081] In an embodiment of the method for manufacturing a liquid crystal panel of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com