Planning method for fairing regions of fairing processing

An area and smoothing technology, applied in the direction of optical devices, instruments, calculations, etc., can solve the problems of reducing smoothing work efficiency, deterioration of low-frequency surface shape, and increasing smoothing time, so as to improve smoothing efficiency and reduce processing area , to prevent the effect of rapid deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

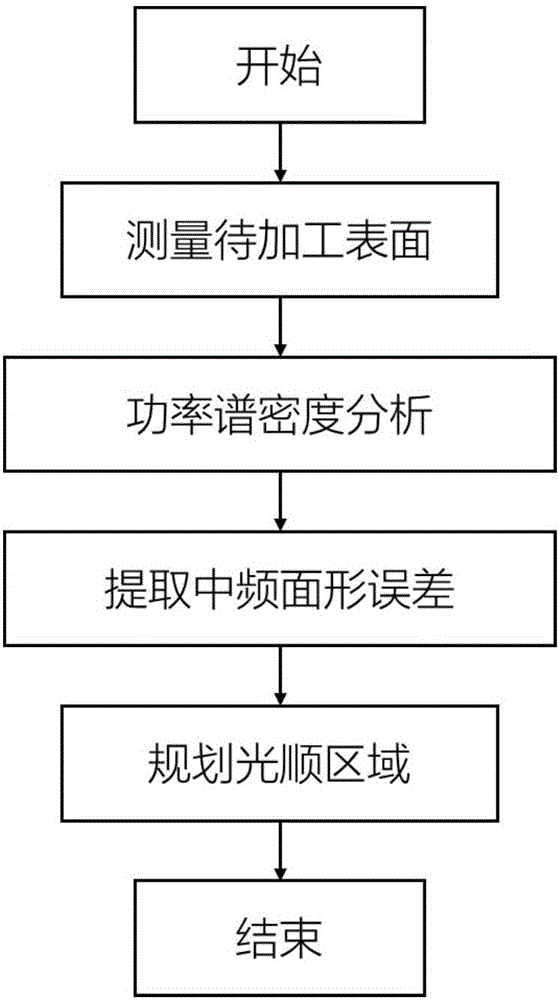

[0028] Such as figure 1 As shown, the process of planning the smoothing area for smoothing processing is mainly divided into four steps: measuring the surface to be processed; power spectral density (referred to as PSD) analysis; extracting intermediate frequency surface shape errors; planning the smoothing area.

[0029] The present invention will be described below in conjunction with a preferred specific embodiment.

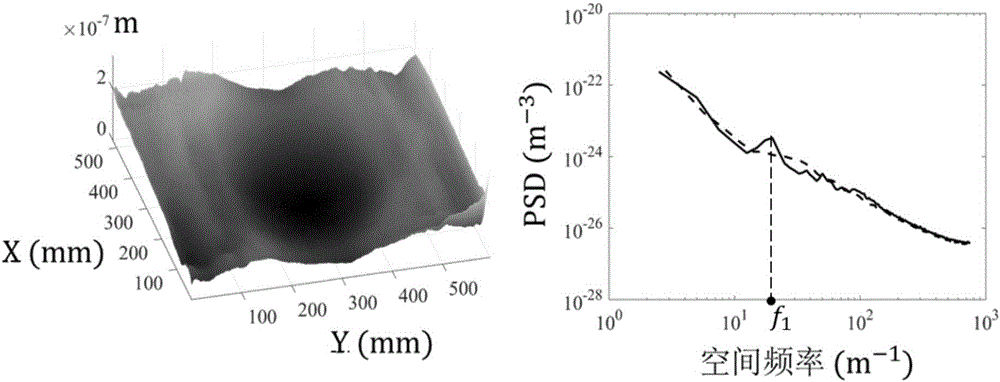

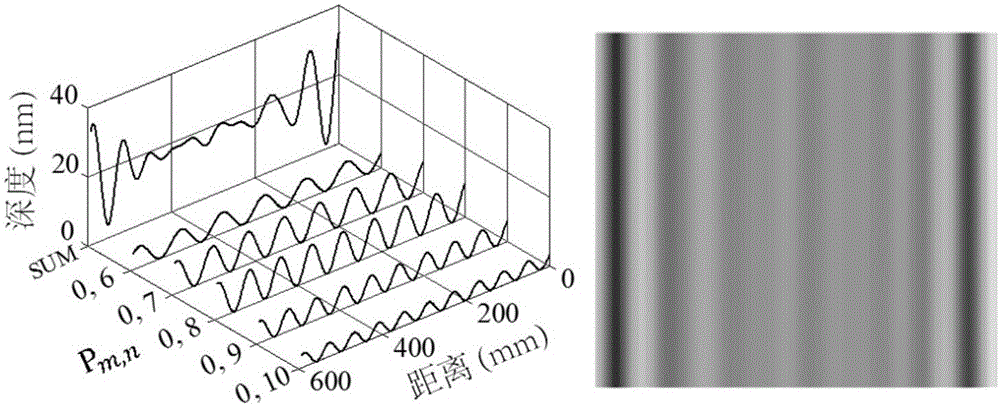

[0030] It should be noted that before using the interferometer to measure the surface shape, the optical elements used in this embodiment have been polished by multiple rounds of small grinding heads. In the polishing process of the small grinding head, since the raster scanning method is used for surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com