Methods of Tungsten Deposition

A kind of chemical vapor deposition, deposition technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

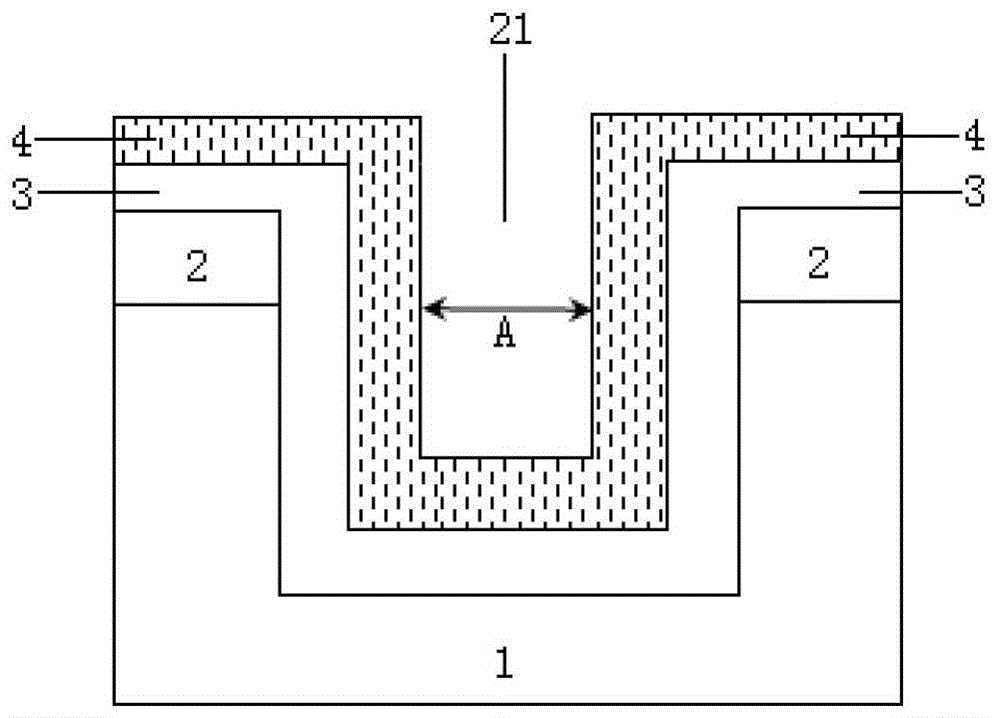

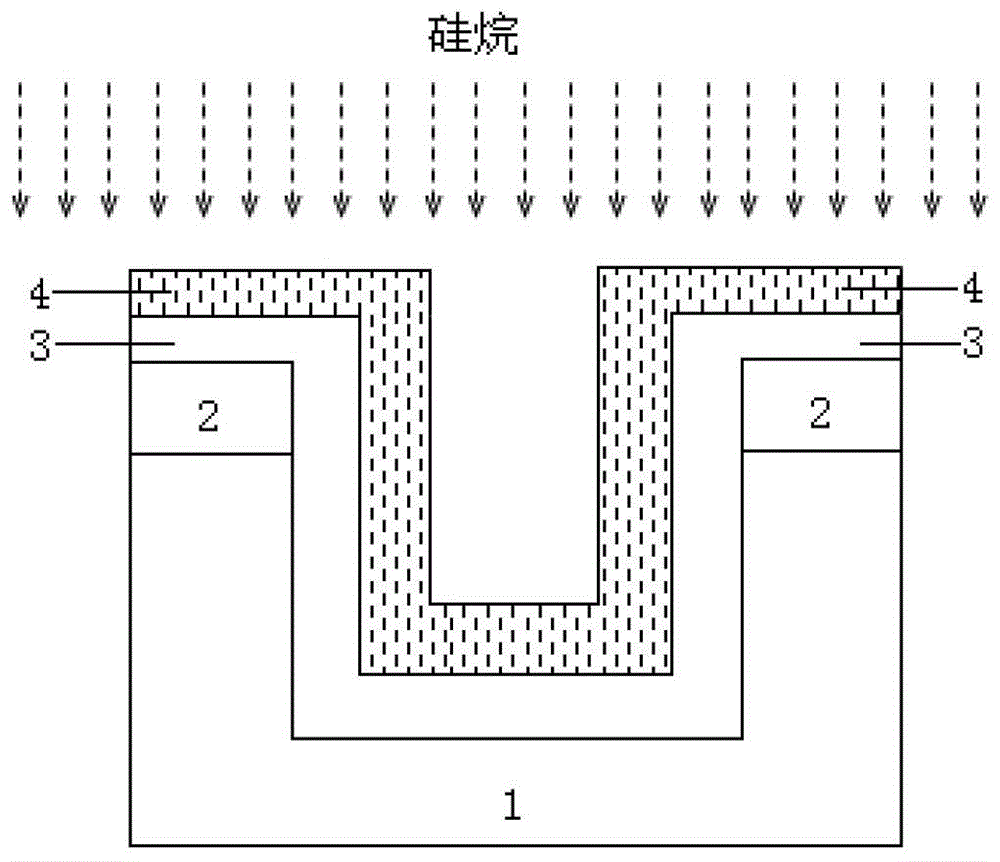

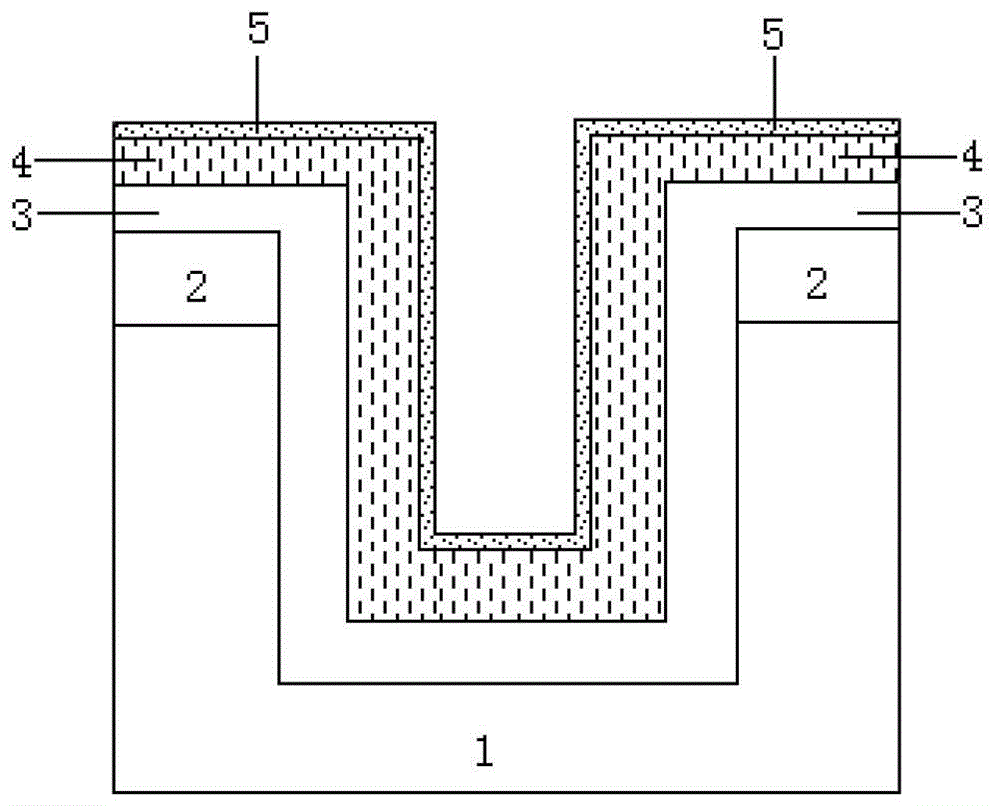

[0043] The method for tungsten deposition of the present invention comprises the steps of:

[0044] (1) On the silicon wafer 1, a layer of dielectric film 2 is deposited by subatmospheric pressure chemical vapor deposition, plasma enhanced chemical vapor deposition, high density plasma chemical vapor deposition or similar methods;

[0045] Wherein, the material of the dielectric film 2 includes: silicon dioxide, doped silicon dioxide or a combined material composed of silicon dioxide and doped silicon dioxide. The doping elements include: phosphorus, boron, fluorine, carbon or combinations thereof.

[0046] Composite materials consisting of silicon dioxide and doped silicon dioxide can be prepared by depositing doped silicon dioxide on undoped silicon dioxide, or by depositing undoped silicon dioxide on doped silicon dioxide. Doped silica, or their composite materials formed by repeated cycle deposition combinations.

[0047] (2) The pattern 21 of the dielectric film 2 is defi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com