Red mud-based cementing material activator and red mud-based goaf filling material

A filling material and activator technology, which is applied in the field of industrial waste resource utilization to achieve the effects of inhibiting volume shrinkage, good fluidity and compressive strength, and solving the problem of voiding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

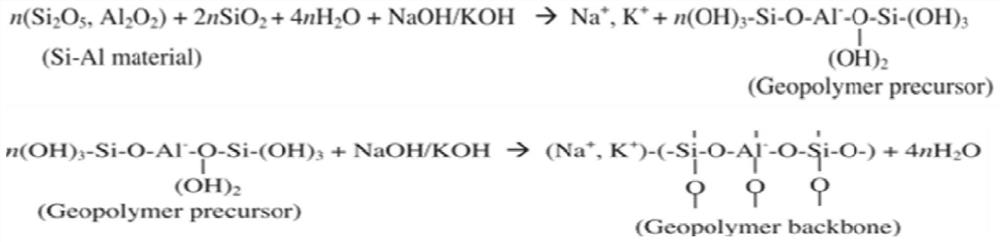

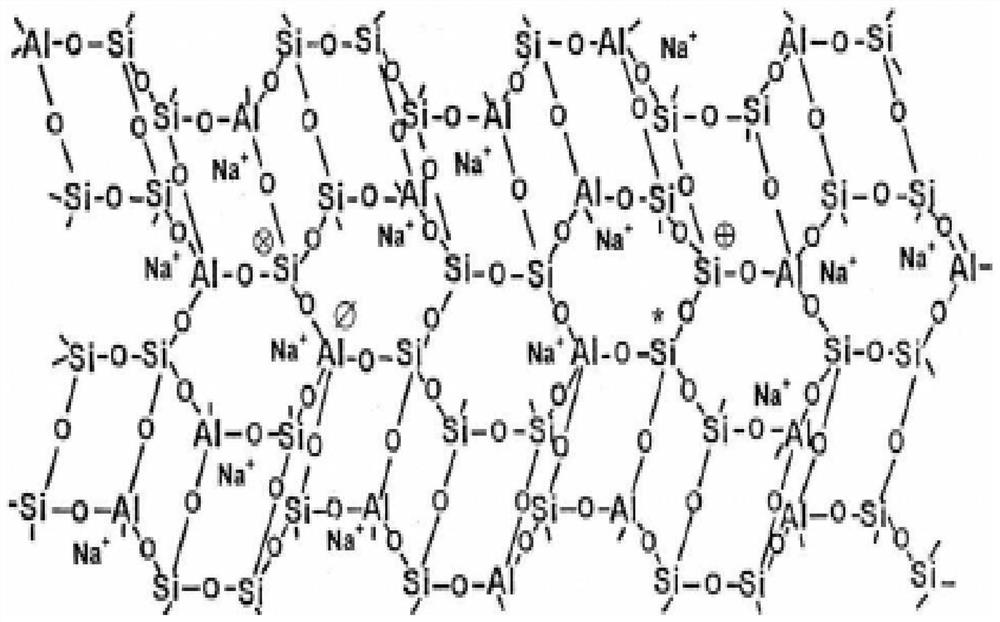

Method used

Image

Examples

Embodiment 1

[0043] The raw material composition of the red mud-based cementitious material composite activator in this example is shown in Table 1.

[0044] Table 1 composite activator embodiment 1 raw material composition

[0045] raw material parts by mass Desulfurization gypsum 30 fly ash 20 soda ash 5 Glauber's salt 10 Natron 10 Sodium dihydrogen phosphate 10 Bauxite 15

[0046] Composite activator embodiment 2

[0047] The raw material composition of the red mud-based cementitious material composite activator in this example is shown in Table 2.

[0048] Table 2 Composite activator embodiment 2 raw material composition

[0049]

[0050]

[0051] Composite activator embodiment 3

[0052] The raw material composition of the red mud-based cementitious material composite activator in this example is shown in Table 3.

[0053] Table 3 composite activator embodiment 3 raw material composition

[0054] raw materi...

Embodiment 2

[0064] The raw material composition of the red mud-based goaf filling material in this example is shown in Table 5.

[0065] Table 5 Composition of Red Mud-Based Goaf Filling Material Example 2 Raw Materials

[0066] raw material parts by mass red mud 40 steel slag 10 Composite activator embodiment 1 22 42.5 Ordinary Portland cement 10 Basalt fiber chopped strand 9 Sericite reinforced polypropylene masterbatch 9

Embodiment 3

[0068] The raw material composition of the red mud-based goaf filling material in this example is shown in Table 6.

[0069] Table 6 Raw material composition of embodiment 3 of red mud-based goaf filling material

[0070] raw material parts by mass red mud 30 steel slag 20 Composite activator embodiment 1 18 42.5 Ordinary Portland cement 10 Basalt fiber chopped strand 11 Sericite reinforced polypropylene masterbatch 11

[0071] The preparation method of sericite reinforced polypropylene masterbatch is as follows:

[0072] Weigh sericite powder and polypropylene granules according to a mass ratio of 1:1, mix them evenly, melt them, blend and extrude them with an extruder, cool and drag them to a pelletizer and cut them into sericite-reinforced polypropylene masterbatches.

[0073] The preparation method of Examples 1-3 of the red mud-based goaf filling material is as follows:

[0074] Weigh each raw material according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com