Multi-component accurate controllable filling system and method

A filling system and multi-component technology, which is applied in the field of automatic production equipment, can solve the problems of reduced use accuracy and inability to replace formulas, and achieve the effects of long practical life and high filling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described below in conjunction with the accompanying drawings.

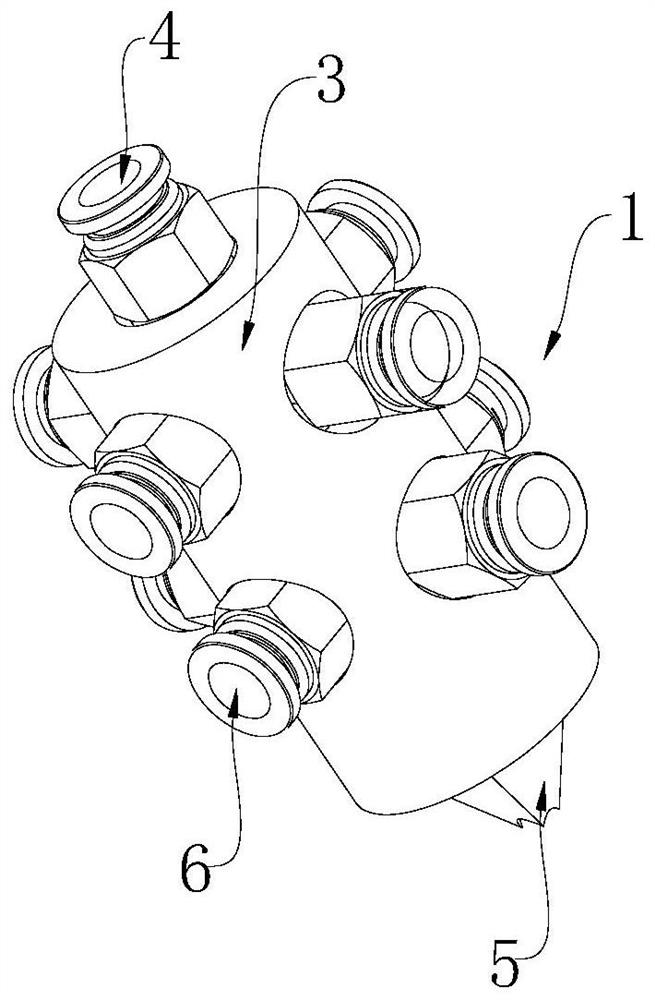

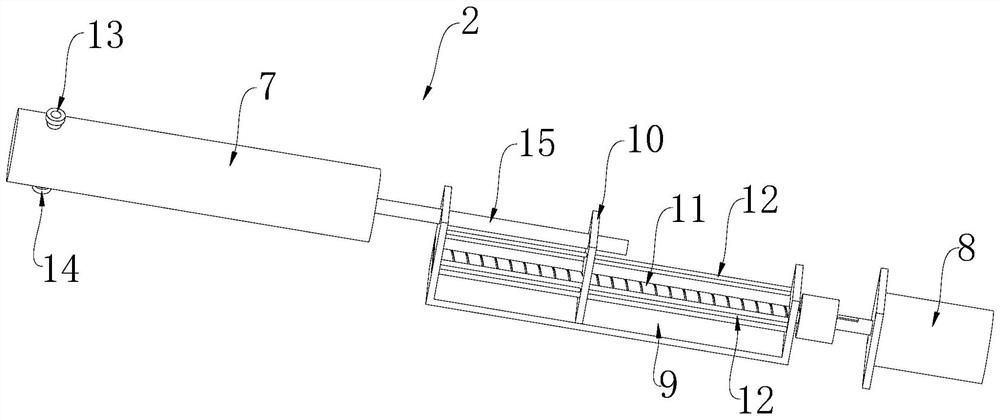

[0022] Please refer to figure 1 with 2 , the embodiment of the present application provides a multi-component accurately controllable filling system, including a filling head 1 and a plurality of feeding components 2 .

[0023] Please refer to figure 1 Specifically, the filling head 1 includes a hollow housing 3, an air purge port 4 disposed at the upper end of the housing 3, a discharge nozzle 5 disposed at the lower end of the housing 3, and a discharge nozzle 5 disposed at the upper end of the housing 3. A plurality of feed openings 6 on the outer wall of the housing 3 . The casing 3 is a hollow cylinder, the inside of which is used to temporarily store the mixed material to be filled outside. The air purge port 4 is a tubular joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com