Adsorption stirring kettle

A stirring tank and stirring shaft technology, applied in the field of stirring tanks, can solve the problems of affecting the service life of resin, low adsorption efficiency, instability, etc., and achieve the effects of low production cost, high work efficiency, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

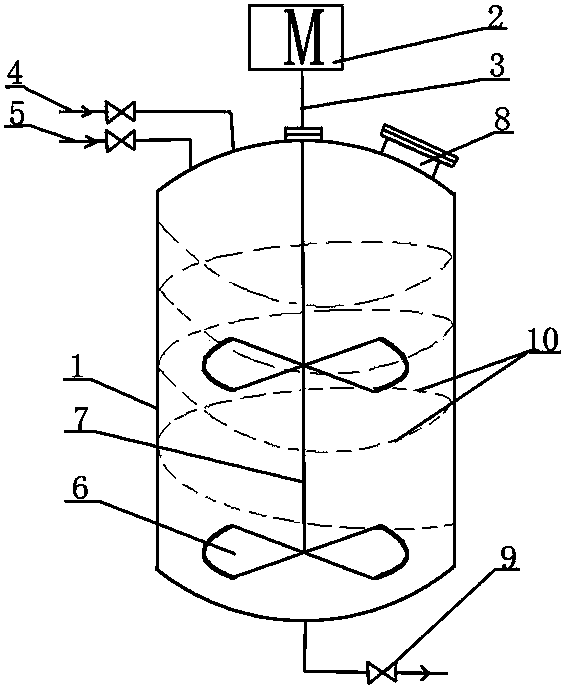

[0011] In order to further illustrate the present invention, introduce below in conjunction with accompanying drawing of description:

[0012] Refer to attached figure 1 , an adsorption stirring tank, which includes a tank body 1, a drive motor 2, a transmission shaft 3, a resin feed pipe 4, an adsorption liquid feed pipe 5, and a stirring blade 6. The upper end of the tank body 1 is equipped with a drive motor 2, and the lower end of the drive motor 2 Connect the transmission shaft 3, the lower end of the transmission shaft 3 is connected to the stirring shaft 7, the stirring shaft 7 penetrates the tank body 1 and goes deep into the tank body 1, the middle and lower ends of the stirring shaft 7 inside the tank body 1 are respectively equipped with stirring blades 6, and the upper end of the tank body 1 is a Resin feed pipe 4 and adsorption liquid feed pipe 5 are installed on the side, manhole 8 is opened on the other side of the upper end of the tank body 1, the manhole 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com