Tobacco leaf intelligent grading system and method based on machine vision and hyperspectral technology

A machine vision and hyperspectral technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of tobacco leaf price disputes, tobacco leaf difficulties, high grading costs, improve efficiency and objectivity, simple and stable design structure, and improve grade purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

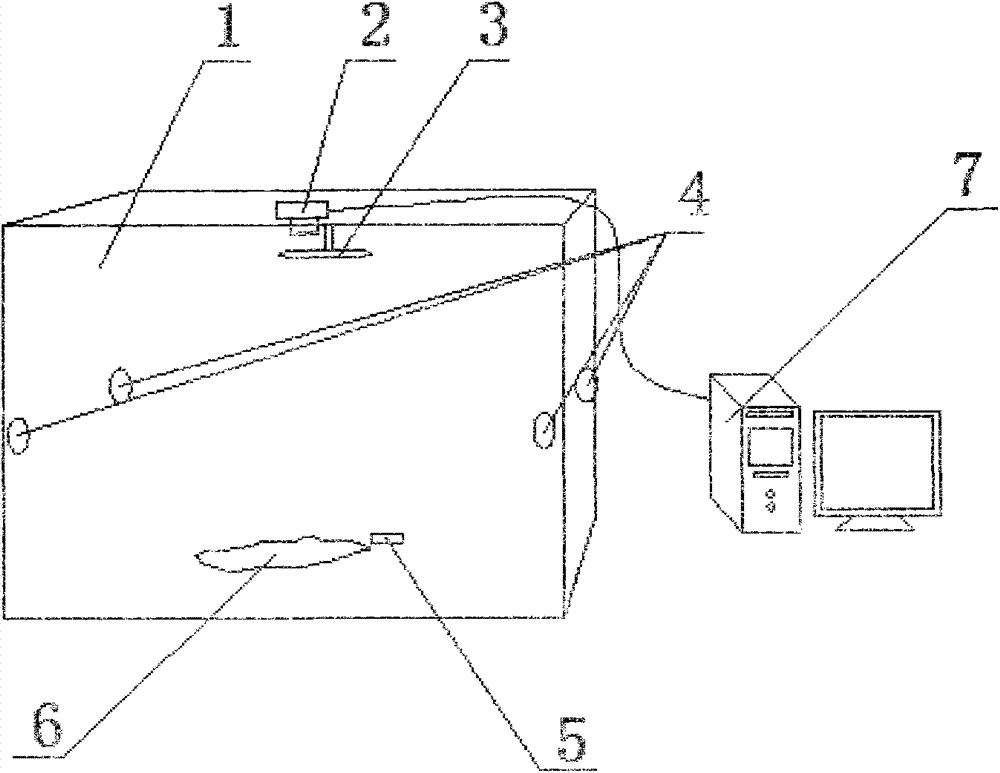

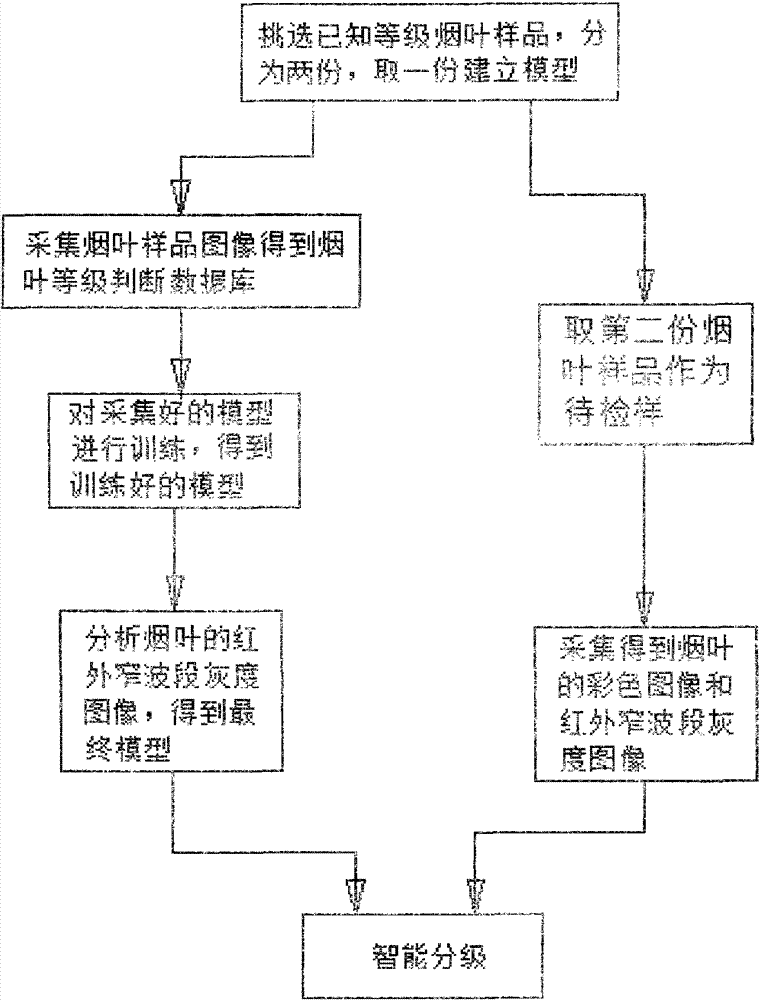

[0023] Such as figure 1 Shown: the tobacco leaf intelligent grading system based on hyperspectral technology of the present invention, comprises light box main body 1 (the inner surface of light box main body is all black diffuse reflection material), industrial CCD2 (can collect the high-definition image of uniform speed moving object in certain speed range, image High quality, and can work continuously for a long time, which is conducive to real-time online automatic grading of tobacco leaves), filter assembly 3 (including filter and its mechanical connection movement device), warm light source group 4, polyvinyl fluoride reference white board 5 (can adjust the light source Fluctuation, CCD thermal noise, vibration and other noises are compensated to ensure the stability of the long-term continuous operation of the system) and the computer 7, the light box main body 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com