Overlying rock isolation grouting filling fly ash slurry compression test system and method

An isolated grouting and experimental system technology, applied in the field of overburden rock isolation grouting filling fly ash slurry compression experiment system, can solve the problem that the overlying rock isolation grouting can not be used to fill the compression characteristics of fly ash slurry, and can not be used to study powder The compression characteristics of coal ash slurry and the inability to obtain the compression coefficient of fly ash slurry have achieved the effect of simple structure, convenient operation and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

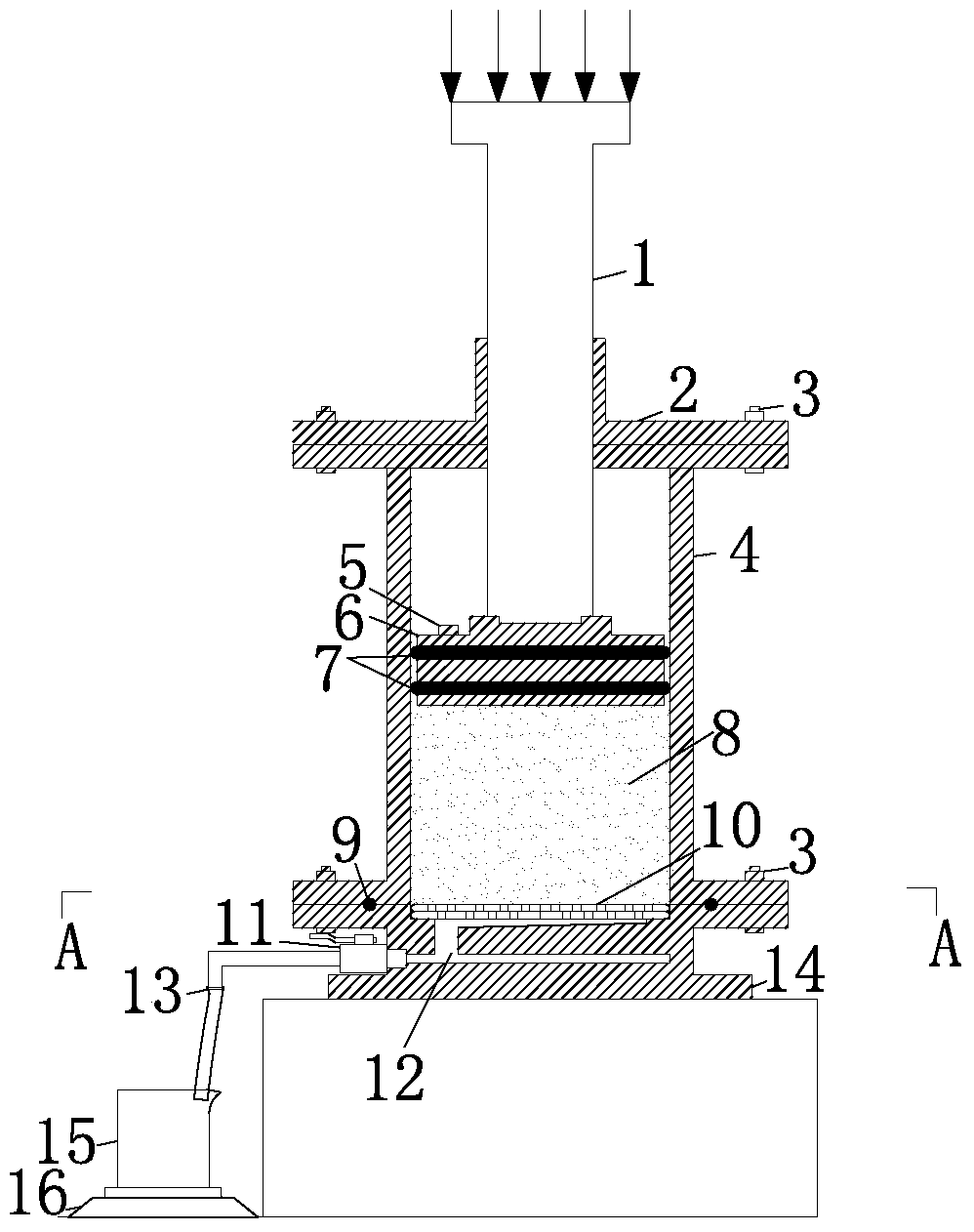

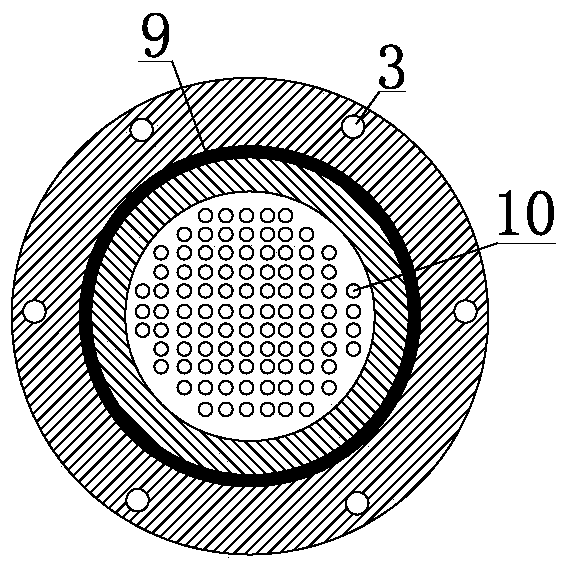

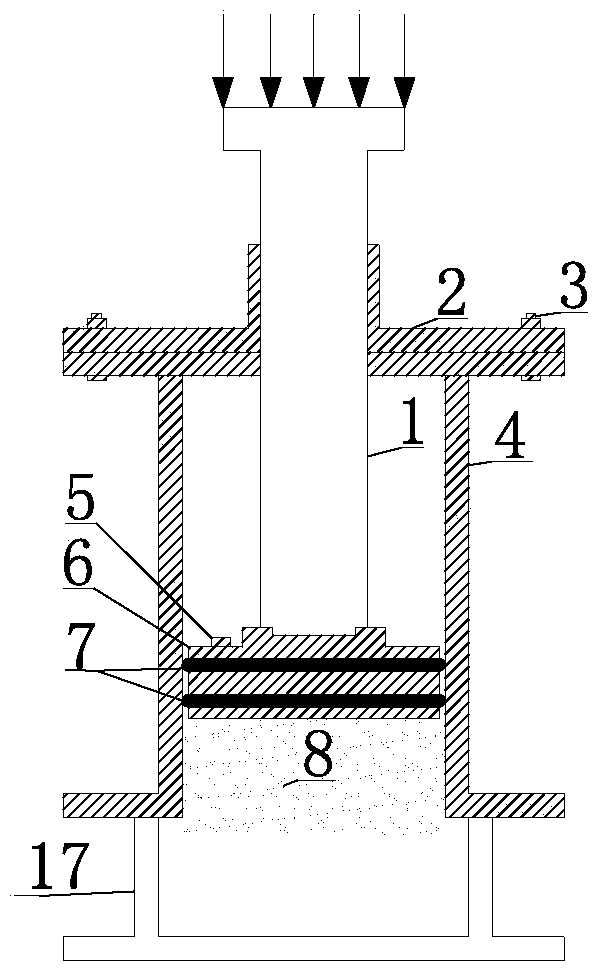

[0020] Such as figure 1 As shown, the overlying rock isolation grouting filling fly ash slurry compression experiment system of the present invention includes a slurry compression device, a bleeding base, a bleeding collection device, and an ash extraction base 17; the slurry compression device includes a columnar structure The mortar bucket 4 is provided with a top cover 2 on the top and a pressurizing piston is arranged inside. The pressurizing piston includes a pressurizing rod 1 and a piston head arranged inside the mortar tank 4 and connected with the pressurizing rod 1. 6. The side of the piston 6 is provided with a multi-strand piston sealing rubber ring 7, and the piston head 6 is provided with a vent bolt 5; the bleeding base includes a base 14 matching the mortar bucket 4, and the mortar bucket 4 is A base sealing rubber ring 9 is arranged betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com