Compressing mechanism of regular hexagonal prism workblank rack shaping machine

A technology of regular hexagonal prism and pressing mechanism, which is applied in forming/shaping machines, wood processing tools, and dovetail processing, etc. It can solve the problems of difficult positioning and comb precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

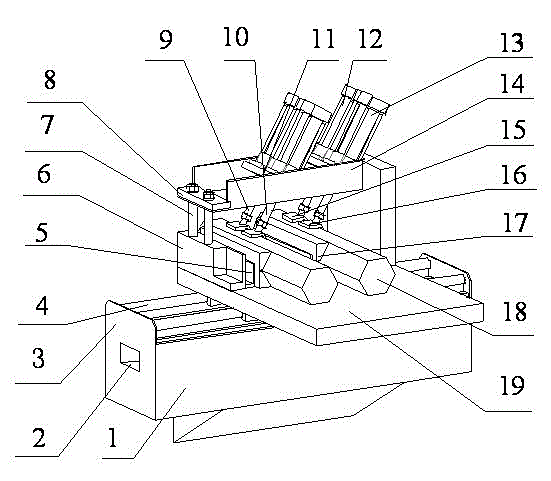

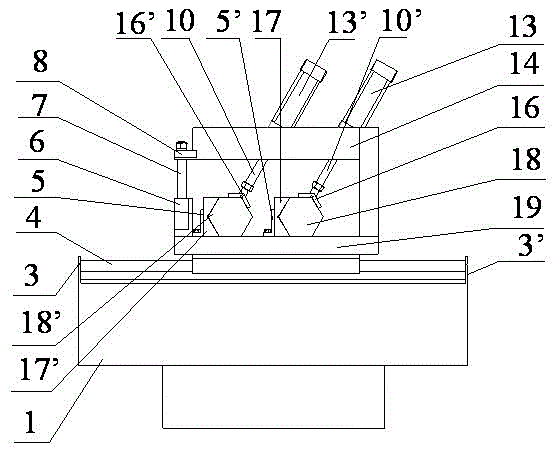

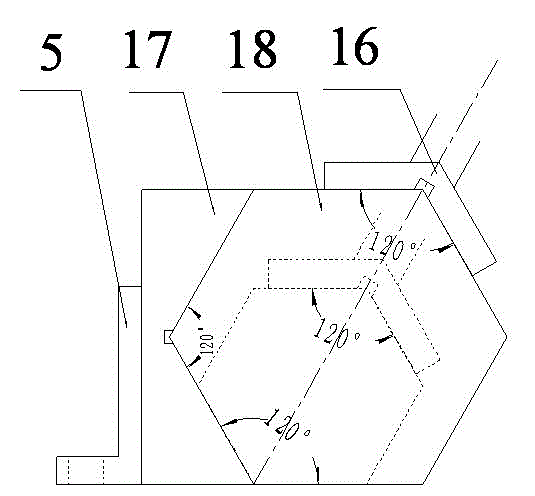

[0021] The present invention will be further described below in conjunction with the accompanying drawings and implementation methods.

[0022] Such as figure 1 , 2 Shown is a schematic diagram of the present invention, which includes body slide rail base 1, notch 2, left and right slide rail baffles 3', 3, front and rear slide rails 4', 4, left and right V-shaped backing fixtures 5', 5, cylinder Frame base 6, cylinder frame fastening screw 7', 7, pad 8, front left and right cylinder pressure rods 9', 9, rear left and right cylinder pressure rods 10', 10, left and right cylinder fixing parts 11', 11. Front left and right cylinders 12', 12, Rear left and right cylinders 13', 13, Cylinder bracket 14, Front left and right V-shaped pressing blocks 15', 15, Rear left and right V-shaped pressing blocks 16', 16, Left and right V Type backers 17', 17, left and right workpieces 18', 18, horizontal workbench 19, etc.

[0023] When the left and right workpieces 18', 18 abut against th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com