Pneumatic press-fitting device and working method thereof

A technology of pneumatic press-fitting and sliding workbench, which is applied in the direction of safety equipment, metal processing equipment, presses, etc., can solve problems such as error-prone, product quality cannot be guaranteed, complex and cumbersome, etc., and achieve safety performance improvement and precision improvement And the effect of high reliability and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific examples.

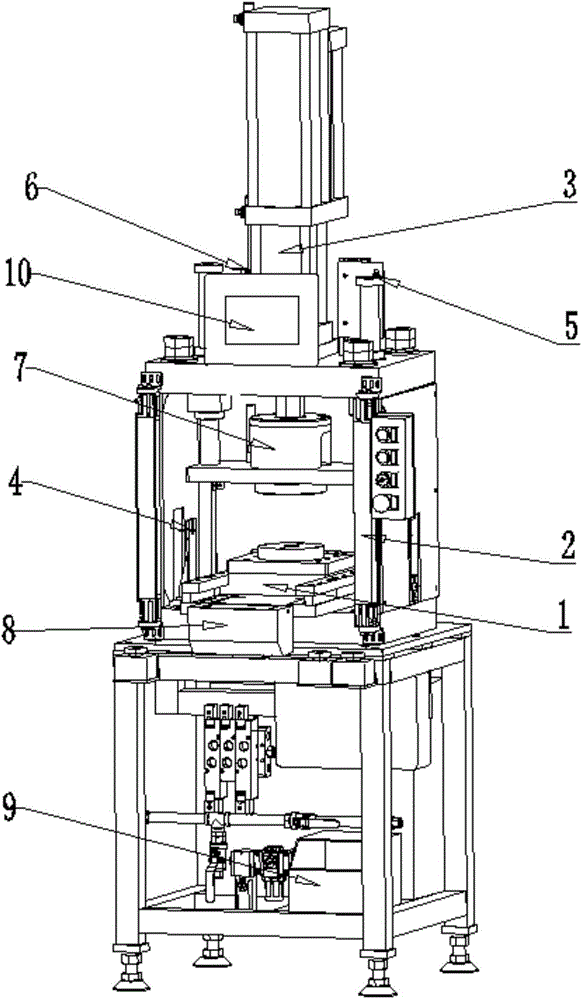

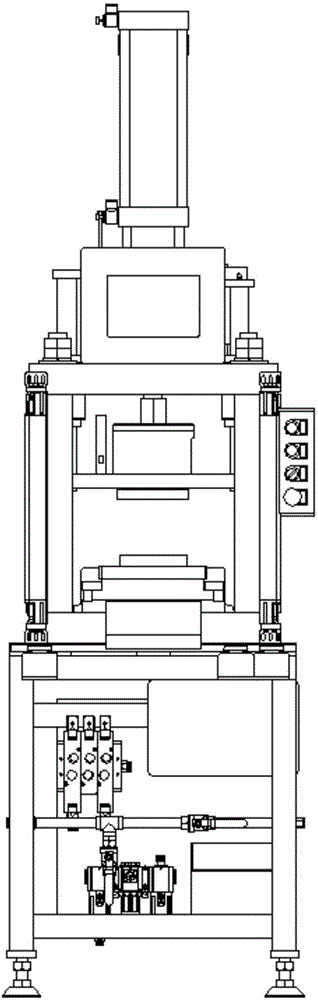

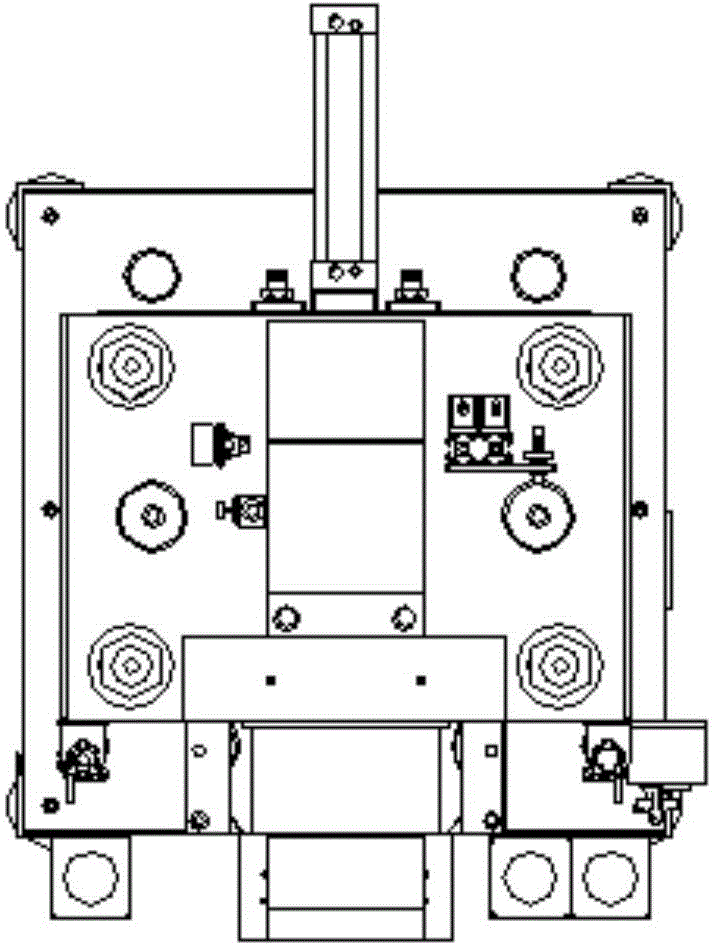

[0030] see Figure 1-4 , a kind of pneumatic press-fitting equipment, set the vertical direction as the Z direction, the left-right direction as the X-direction, and the front-rear direction as the Y-direction; The lower edge slides forward and backward along the Y direction; the sliding workbench 1 slides inward along the Y direction and is provided with an optical fiber sensor 4, and the optical fiber sensor 4 is used to detect the presence or absence of products after the sliding workbench 1 slides in place; the booster cylinder 3 It is the power device of the pneumatic press-fitting equipment. The stroke position of the booster cylinder is provided with a proximity sensor 5 to detect whether the pressurization and return of the booster cylinder are in place; the booster cylinder 3 is provided with a displacement sensor 6 to detect whether the displacement of the booster cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com