Electric driving transmission system for electric vehicle

A technology for electric vehicles and transmission systems, applied in manual starting devices, vehicle components, control devices, etc., can solve the problems of poor operation stability, short service life, short maintenance cycle, etc., and achieve high reliability, long service life, mechanical Low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

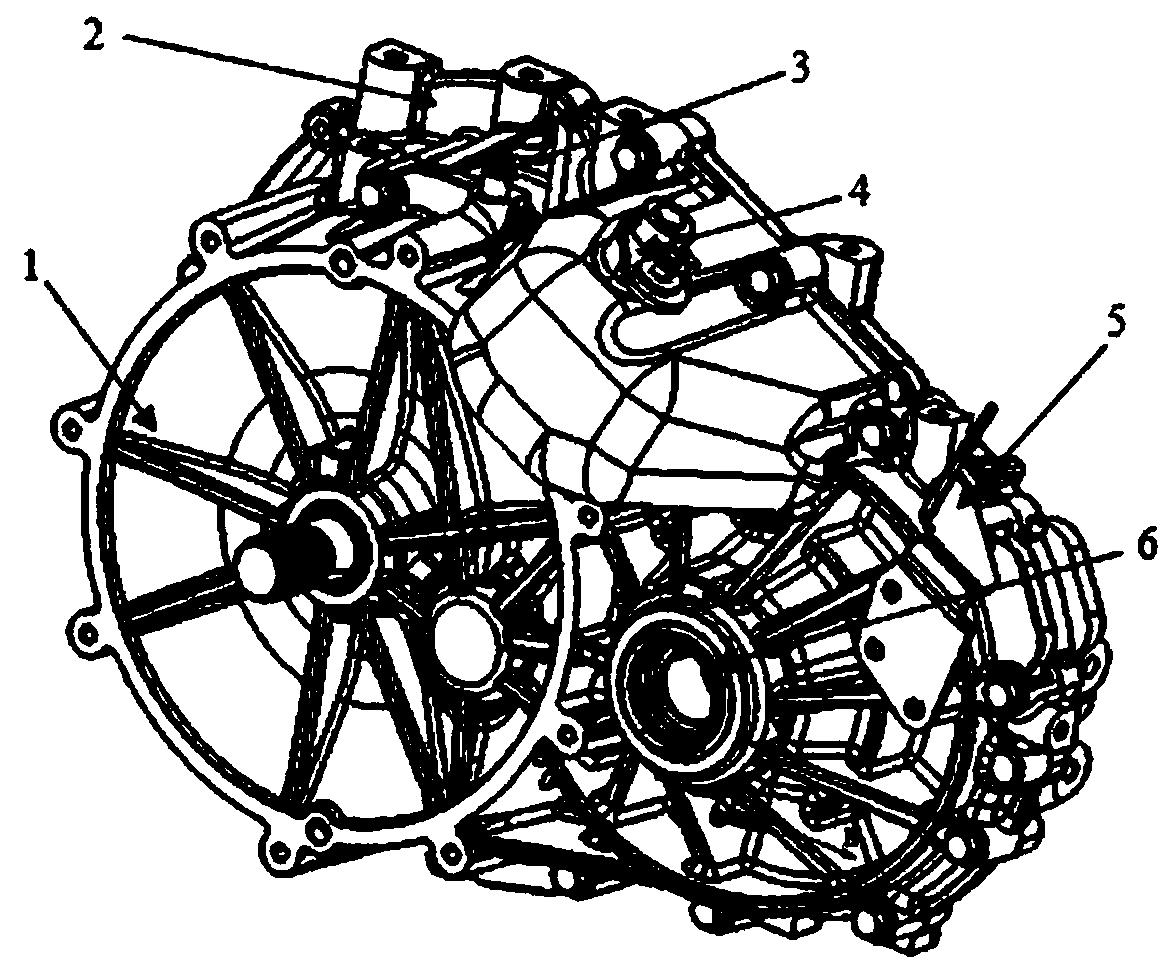

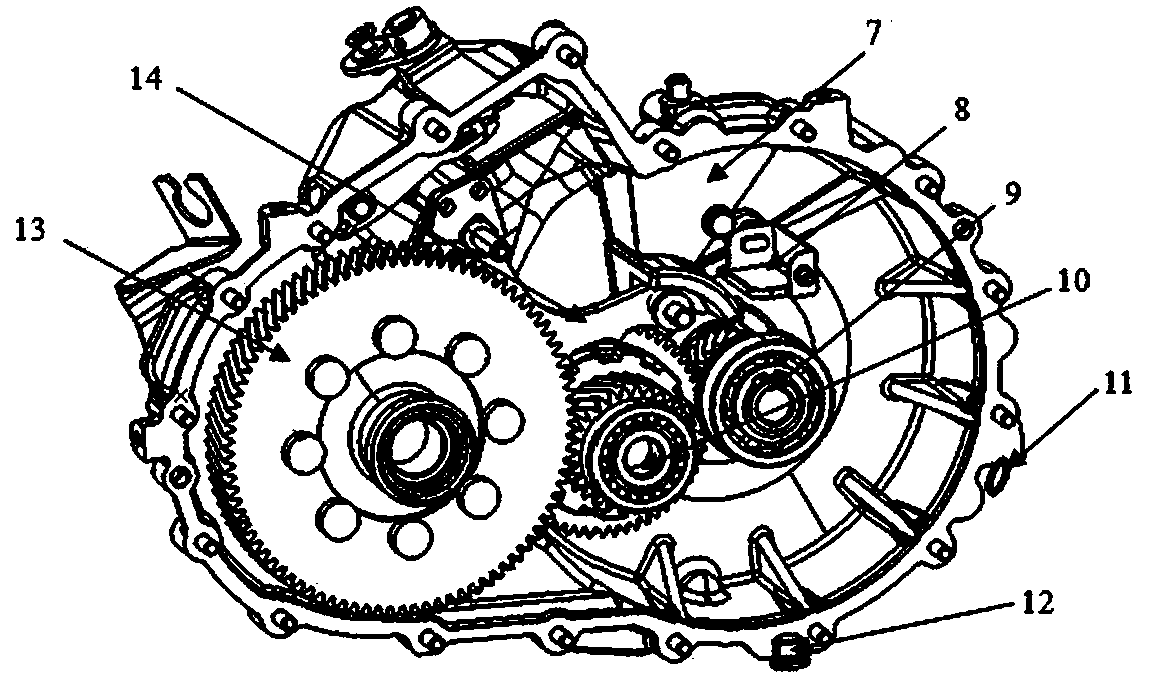

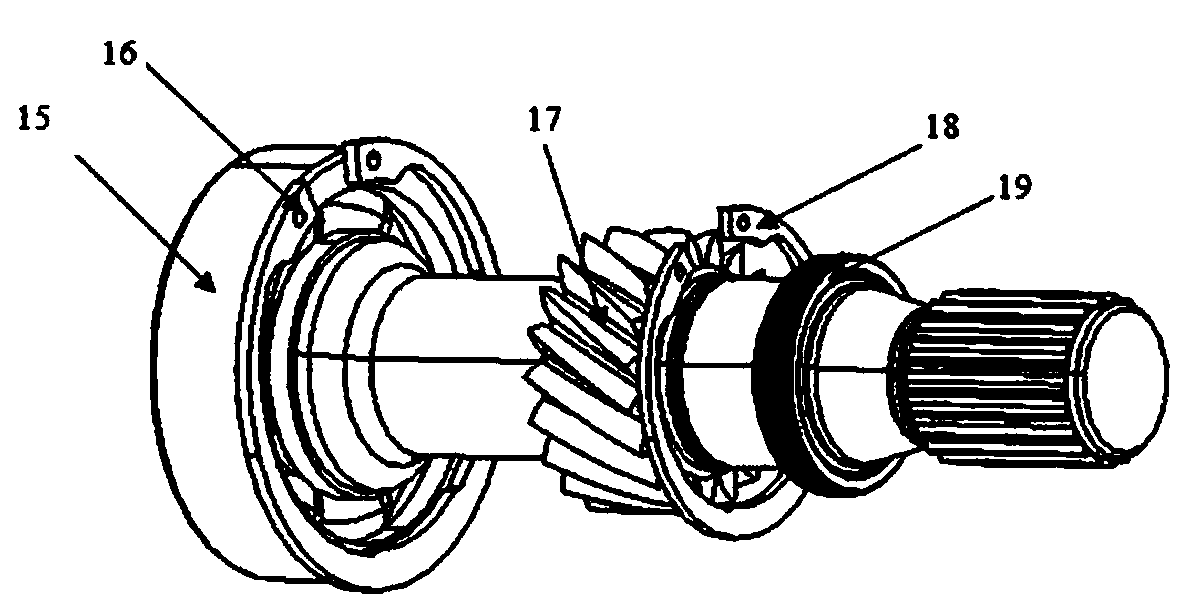

[0017] according to Figure 1~6 The specific structure of the present invention will be described in detail. The electric drive transmission system for electric vehicles includes a drive housing, the top of the drive housing is provided with a vent plug 3, the bottom is provided with an oil discharge hole, the oil discharge hole is provided with an oil discharge screw plug 12, and the drive housing is also provided with an oil discharge hole. Blocking washer 11, the driving housing is composed of front housing 1 and rear housing 2, and the driving housing is provided with input shaft subassembly 9, output shaft subassembly 10, differential gear subassembly 13 and brake mechanism subassembly 14. The input shaft sub-assembly 9 is matched with the output shaft sub-assembly 10, and the output shaft sub-assembly 10 is matched with the differential gear sub-assembly 13. The input shaft subassembly 9 includes a deep groove ball bearing 15 limited in the rear shell, a cylindrical rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com