A fully automatic wrapping vacuum packaging machine

A vacuum packaging machine, fully automatic technology, applied in the direction of packaging, packaging, transportation and packaging under vacuum/special atmosphere, can solve the problems of cluttered, imperfect, no automatic collection, etc. Simple and perfect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

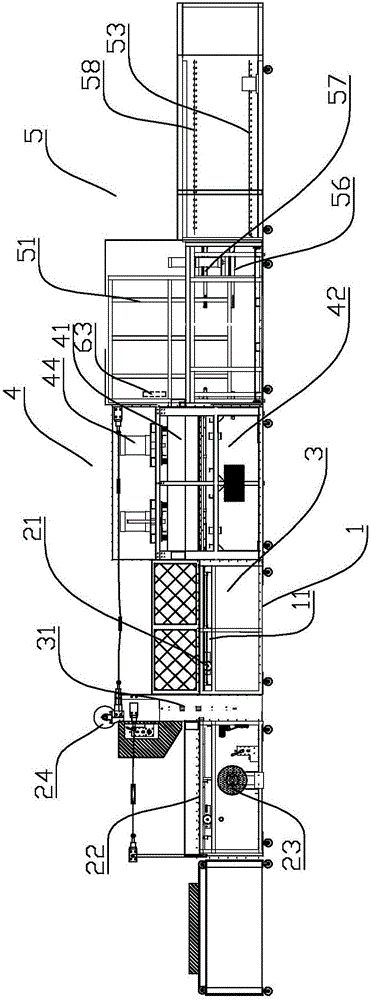

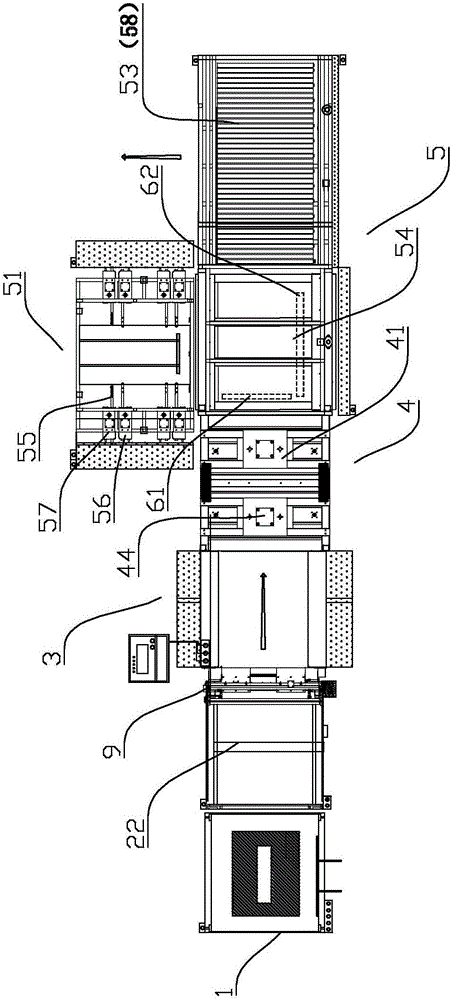

[0024] refer to Figure 1 ~ Figure 2 The invention is a fully automatic wrapping vacuum packaging machine, comprising:

[0025] Frame 1, a second conveyor belt 11 is arranged in the frame 1, and the object to be packaged is transported to the subsequent process through the second conveyor belt 11;

[0026] The film material wrapping device includes a film pulling manipulator 21, a rotatable first conveyor belt 22 installed on the frame 1, a film unwinding roll 23 and a film winding roll 24, and the film unwinding roll 23 and the film winding roll 24 both have a power system Control drive, the first conveyer belt 22 is positioned at the front of the second conveyer belt 11, and the adhesive film released by the film release roll 23 is connected with the film roll 24, and the film pulling manipulator 21 can pull the film between the film release roll 23 and the film roll 24 Adhesive film can be pulled to partially overlapped state by being pulled by the film pulling manipulator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com