Chain conveying type vehicle bumper spraying line

A technology for conveying automobile bumpers and chains, applied in conveyors, transportation and packaging, etc., can solve the problems of poor spatial adaptability and high manufacturing cost, and achieve the effects of low frictional resistance, low manufacturing cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the drawings and embodiments.

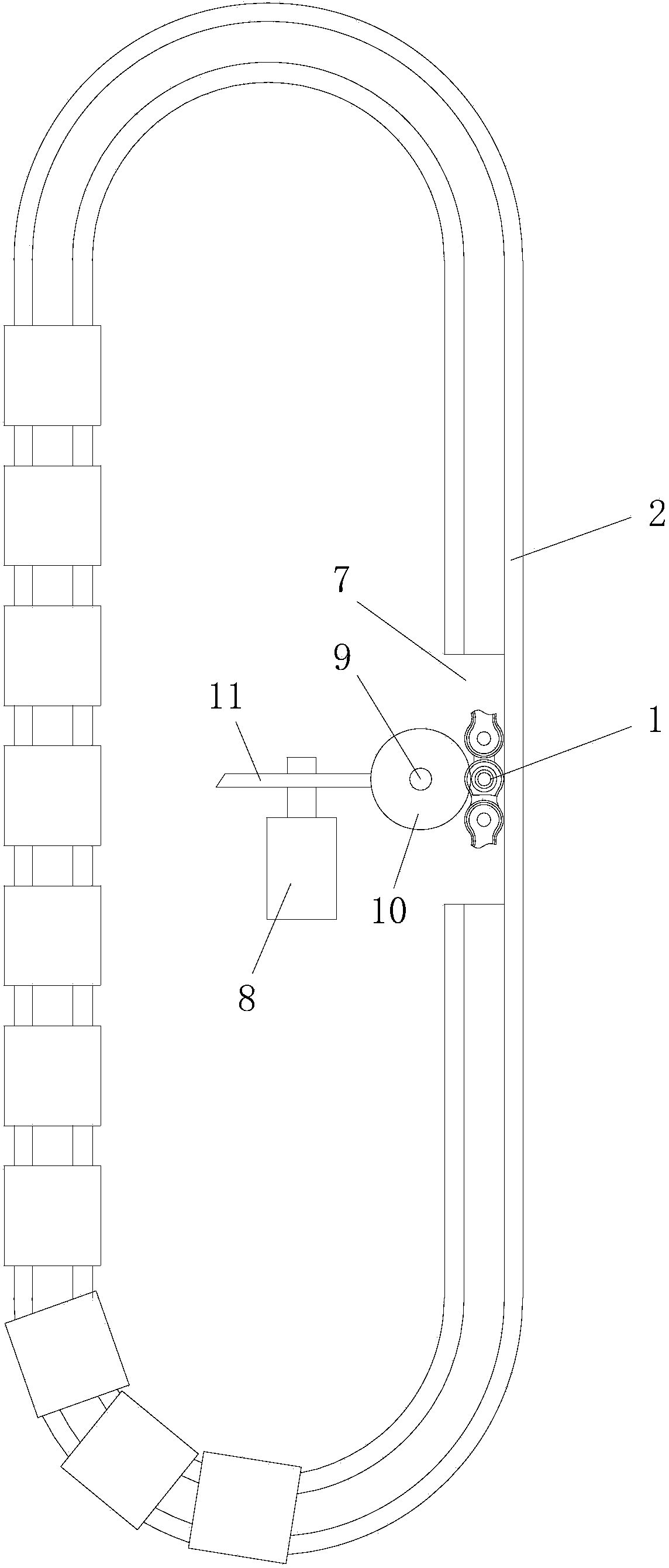

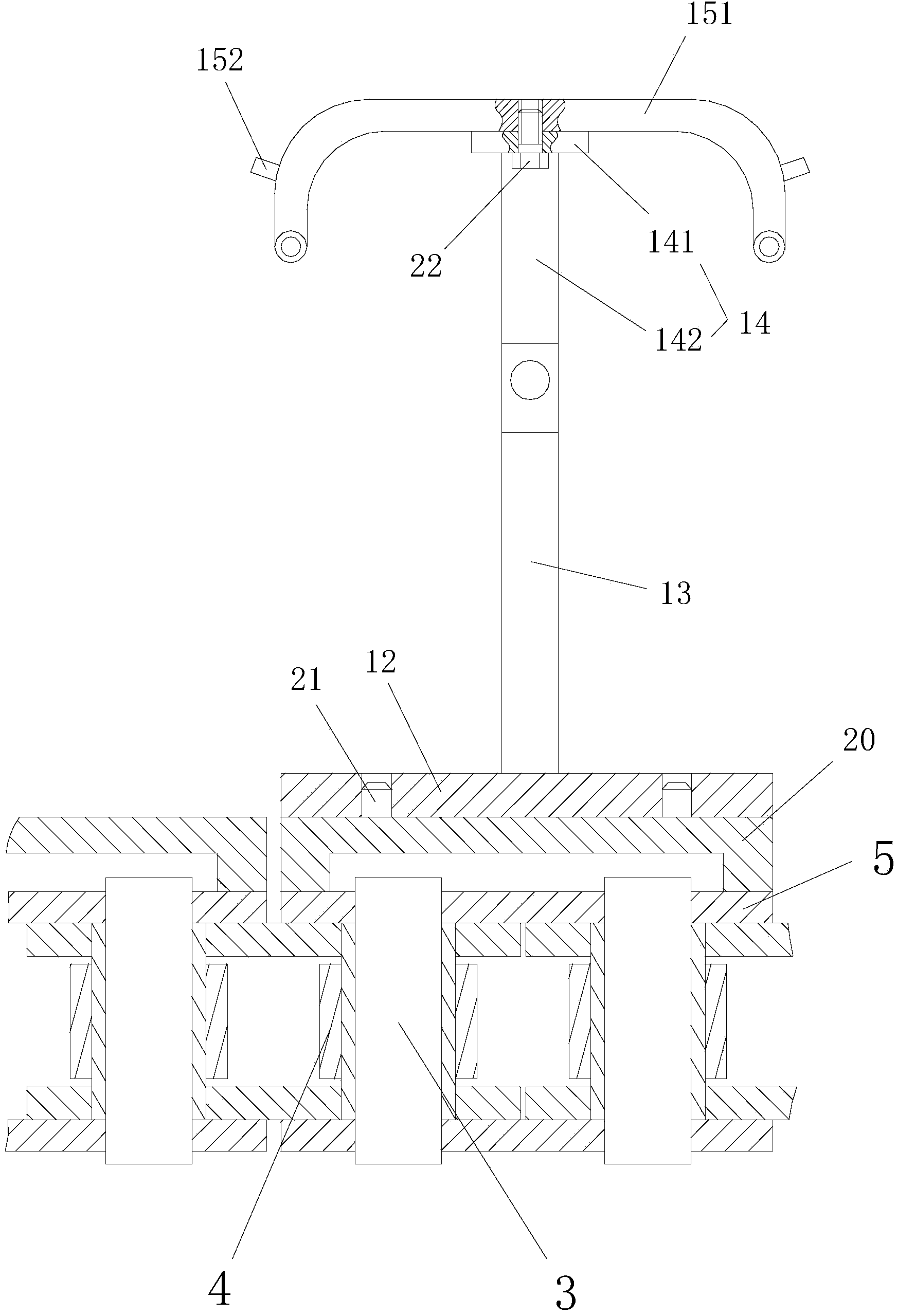

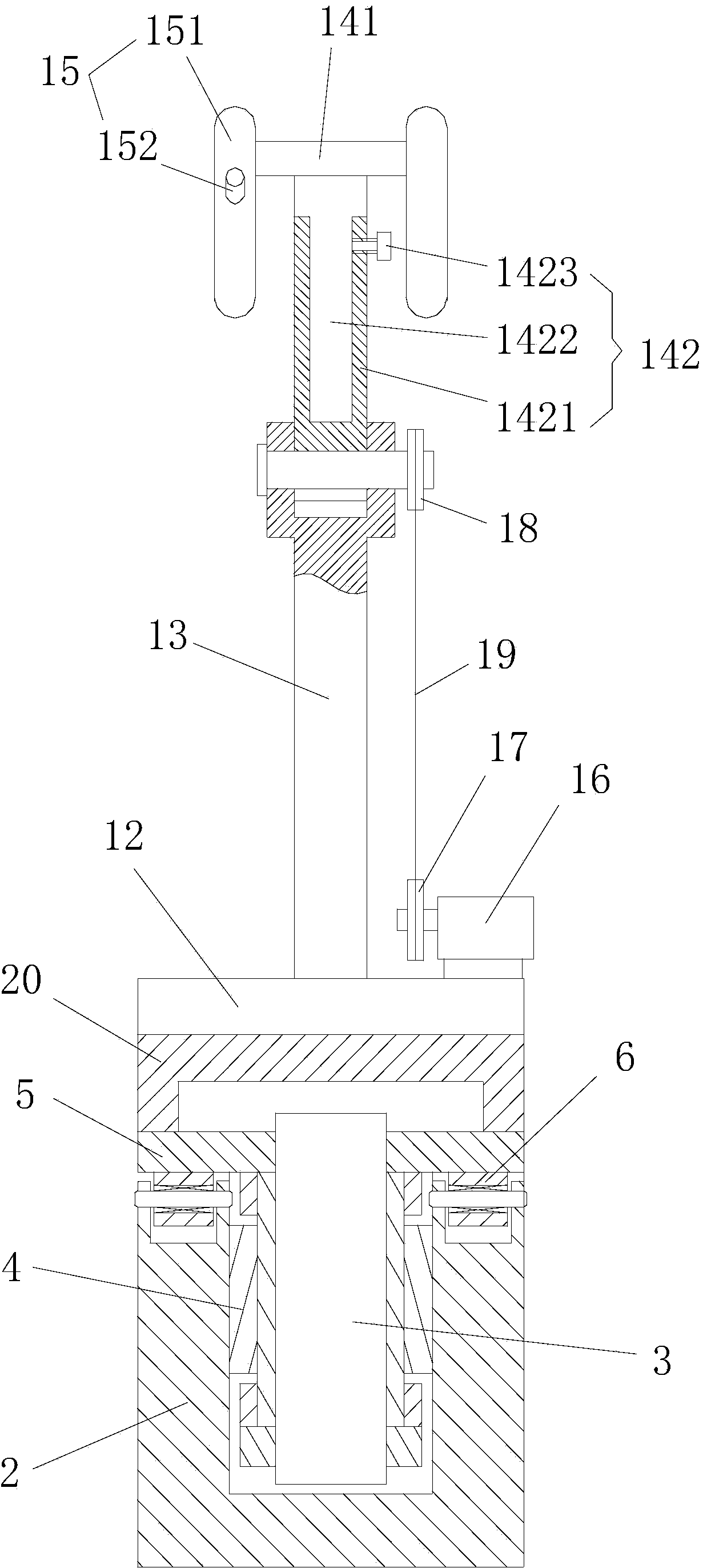

[0024] As shown in the figure, the chain conveyor type automobile bumper spraying line of this embodiment includes a chain 1, an annular track for positioning the chain 2, a chain drive mechanism and a bumper spraying tool;

[0025] The chain includes an axle pin 3, a roller 4 arranged in the middle of the axle pin, and outer connecting plates 5 arranged at both ends of the axle pin;

[0026] The cross section of the ring rail 2 is U-shaped groove shape, the chain 1 is placed in the U-shaped groove of the ring rail, and the shaft pin 3 is arranged vertically in the U-shaped groove, and the outer cylindrical surface of the drum 4 is The groove wall surface of the U-shaped groove is in rolling fit, the outer connecting plate 5 at the upper end of the shaft pin is placed on the notch end surface of the U-shaped groove, and the groove end surface of the U-shaped groove is provid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap