Anti-tracking sheathing material for ADSS (all dielectric self-supporting) optical cables

A technology of electric tracking resistance and sheath material, which is applied in the direction of cables, circuits, electrical components, etc., to achieve the effect of improving electric tracking resistance and environmental stress cracking resistance, performance improvement, and excellent thermal deformation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation process of the present invention is as follows: add polyethylene base material, black masterbatch, polyethylene wax, PPA additives, and antioxidants in a certain proportion and mix them evenly, then pour them into a high-mixer, and then add magnesium hydroxide filler Stir with a high mixer and stop for about 5 minutes. Then use twin-screw extrusion granulation, preheat the twin-screw in advance, set the temperature from the first zone to the ninth zone to 170, 175, 180, 185, 190, 195, 195, 210, set the head temperature to 220, and set the pressure It is 0.25-0.3MPa, the feed is given at 20HZ, and the screw speed is set at 200r / min.

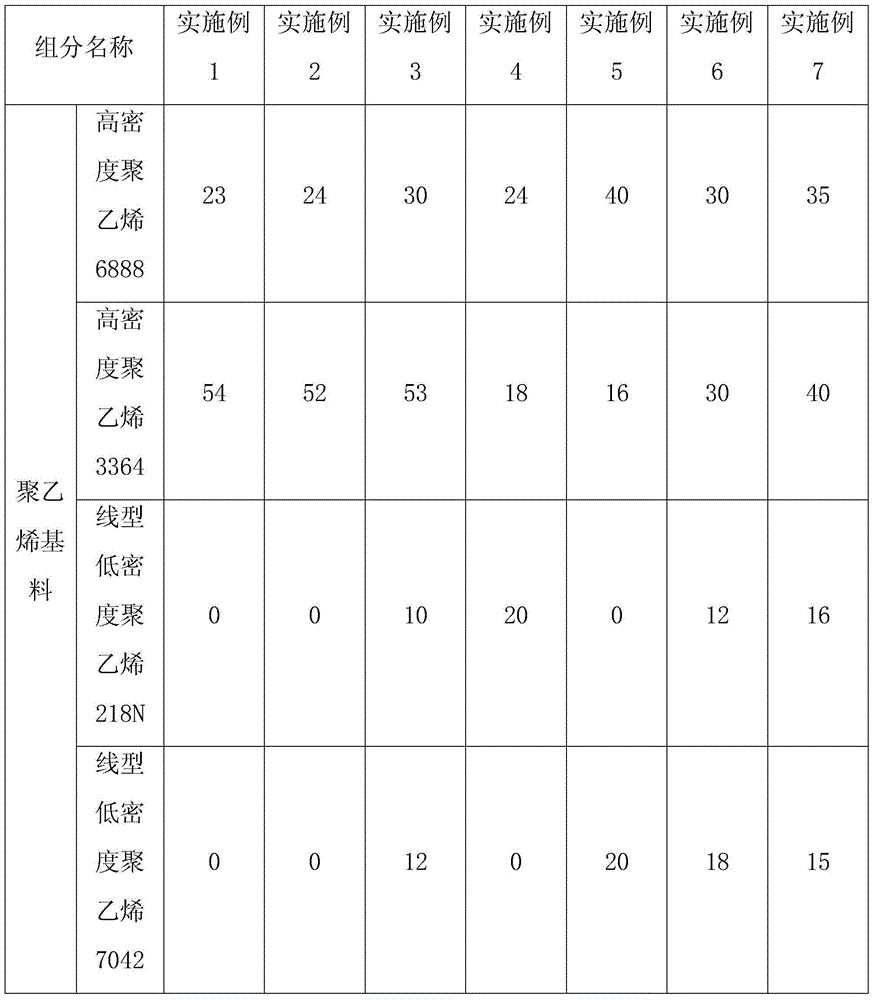

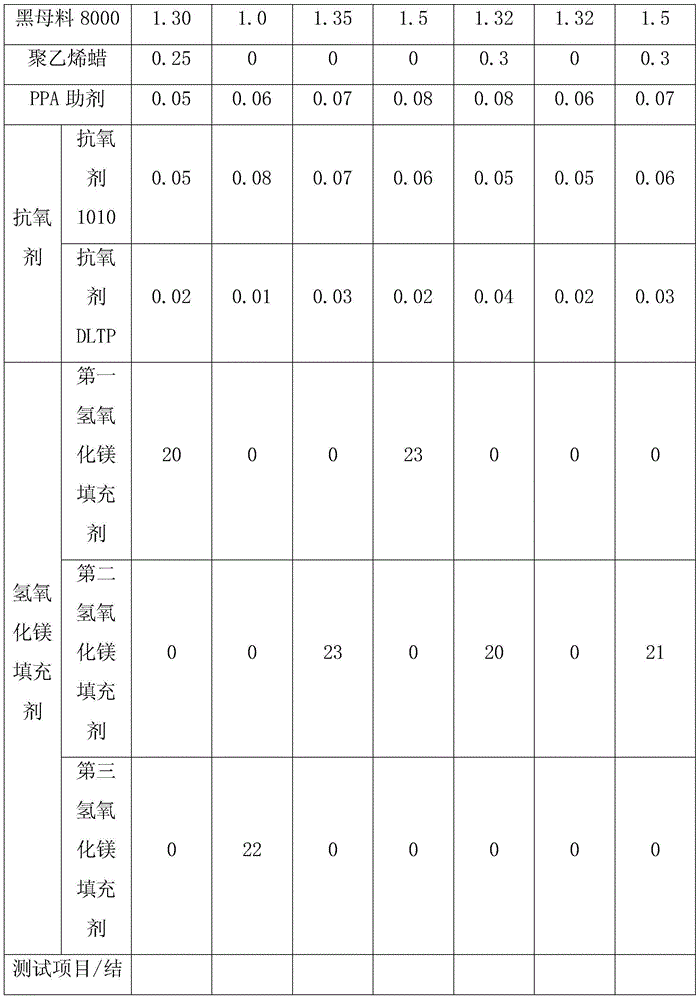

[0035] Table 1 shows the ingredients and test results of the tracking-resistant sheath material for ADSS optical cables described in Examples 1-5.

[0036] Table 1

[0037]

[0038]

[0039]

Embodiment 8

[0040] Simultaneously the present invention provides a kind of most preferred embodiment 8, and its formula is as follows:

[0041] Wherein said polyethylene base material comprises:

[0042] HDPE 6888 37 parts,

[0043] HDPE 3364 20 parts,

[0044] Linear low density polyethylene 218N 0 parts,

[0045] Linear low density polyethylene 7042 20 parts;

[0046] Black masterbatch 8000 1.35 parts;

[0047] Polyethylene wax 0-0.3 parts;

[0048] 0.08 part of PPA additive;

[0049] The antioxidants include:

[0050] Antioxidant 1010 0.05 part,

[0051] Antioxidant DLTP 0.04 parts;

[0052] Described magnesium hydroxide filler comprises:

[0053] 20 parts of the third magnesium hydroxide filler.

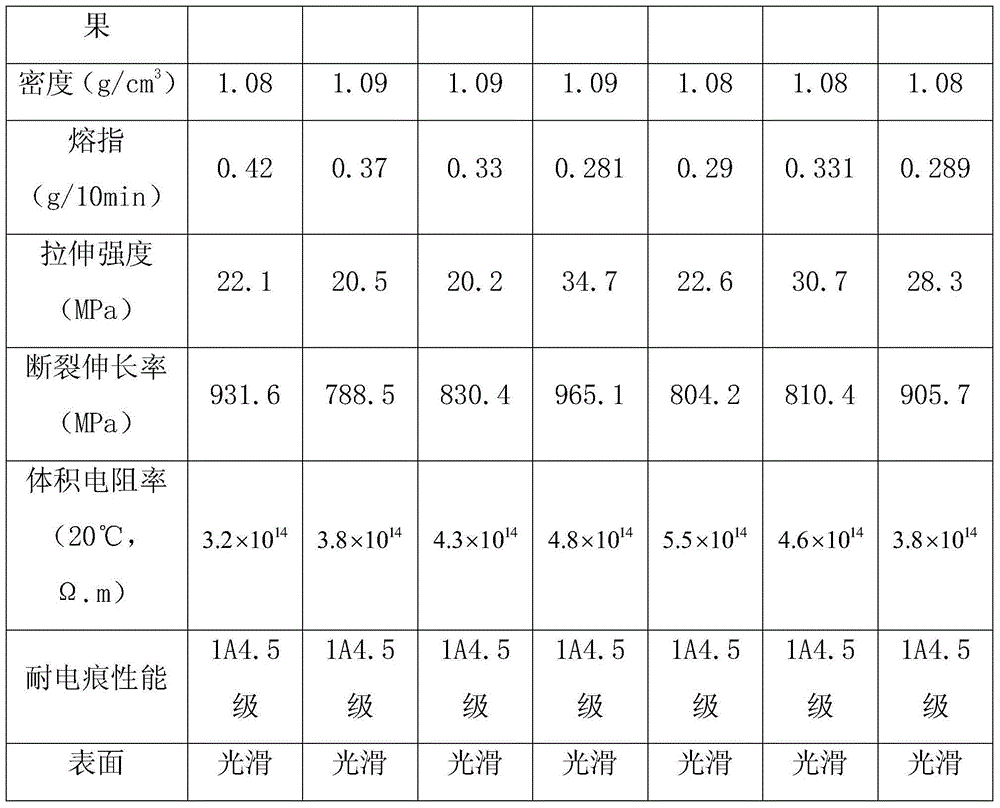

[0054] The performance test of the anti-tracking sheath material for ADSS optical cable obtained in Example 8 is shown in Table 2.

[0055] Table 2

[0056]

[0057] The present invention selects two kinds of high-density polyethylenes to be used in combination. The first reas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com