Marine environmental corrosion-resistant cored wire for aluminium-based amorphous nanocrystalline coating

A technology of amorphous nanocrystalline and powder core wire, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems of high cost, single composition, low amorphous content of the coating, etc., and achieve durability Excellent corrosion resistance, high amorphous content, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: A kind of powder core wire material for marine environment corrosion-resistant aluminum-based amorphous nanocrystalline coating and its preparation method

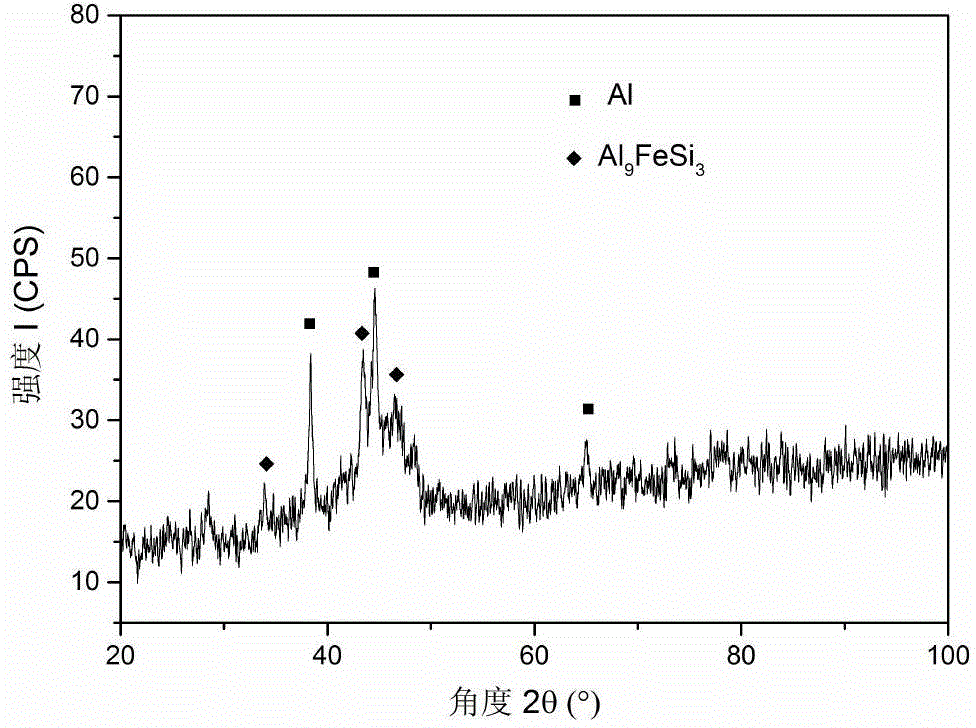

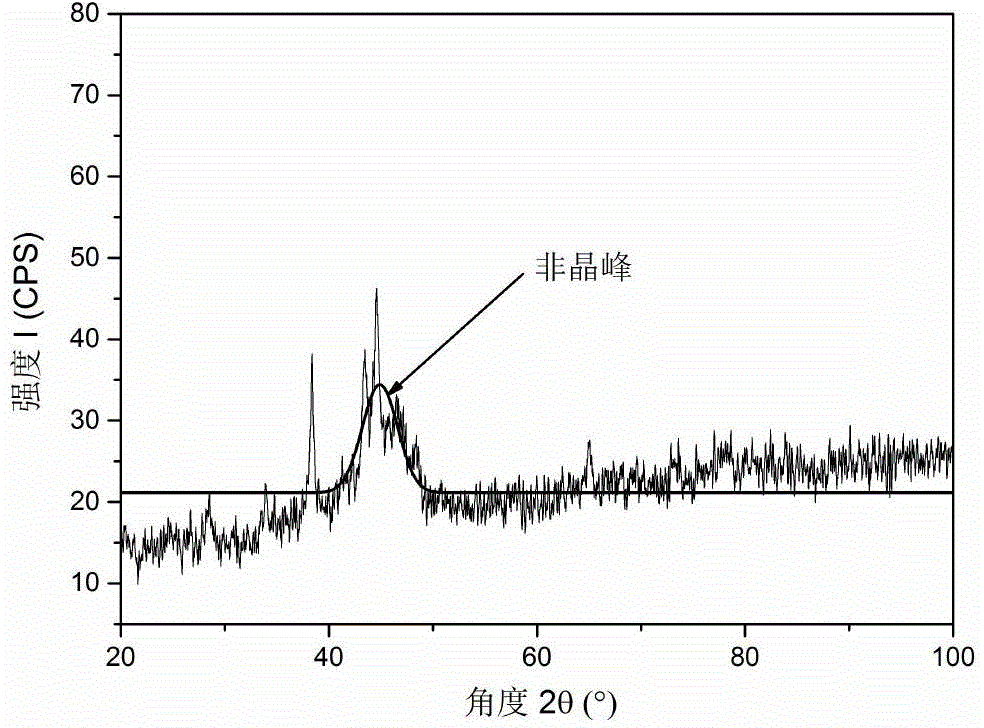

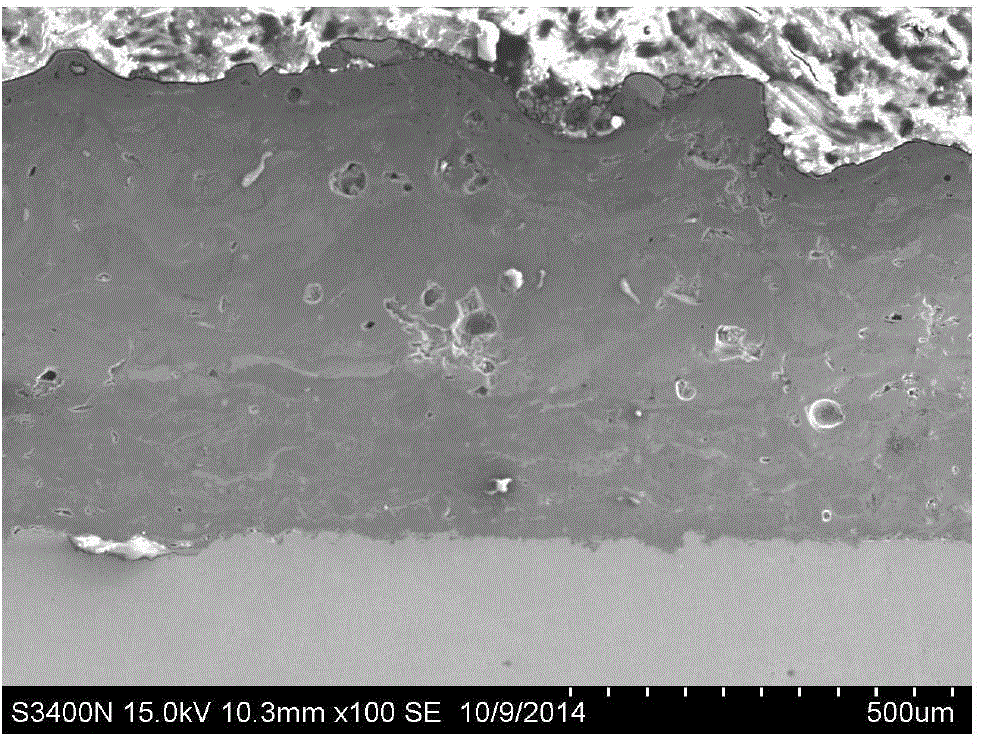

[0024] A pure aluminum strip of 10×0.3mm (width 10mm, thickness 0.3mm) is selected. Tie it into a U shape first. According to the atomic percentage of each element of the powder core wire material: 10 at. % Si, 3 at. % Ni, 8 at. % Fe, and the balance Al, the ingredients are weighed. Put the taken powder into the powder mixer and mix for 30 minutes, then put the mixed powder into the U-shaped aluminum belt groove, and the filling rate is 34%. Then the U-shaped groove is closed, so that the powder is coated in it, and then the diameter is gradually reduced to Φ2mm through the wire drawing die. The finished wire is wound into a disc shape required by the factory, and after being measured and packaged, it becomes a product that can be shipped. The process parameters used for preparing the coating: the spra...

Embodiment 2

[0026] Example 2: A kind of powder core wire material for marine environment corrosion-resistant aluminum-based amorphous nanocrystalline coating and its preparation method

[0027] A pure aluminum strip of 10×0.3mm (width 10mm, thickness 0.3mm) is selected. Tie it into a U shape first. According to the atomic percentage of each element of the core wire material: 12 at. % Si, 5 at. % Ni, 10 at. % Fe, and the balance Al, the ingredients are weighed. Put the taken powder into the powder mixer and mix for 30 minutes, then put the mixed powder into the U-shaped aluminum belt tank, and the filling rate is 36%. Then the U-shaped groove is closed, so that the powder is coated in it, and then the diameter is gradually reduced to Φ2mm through the wire drawing die. The finished wire is wound into a disc shape required by the factory, and after being measured and packaged, it becomes a product that can be shipped. Process parameters used for preparing the coating: the spraying voltage...

Embodiment 3

[0029] Example 3: A kind of powder core wire material for marine environment corrosion-resistant aluminum-based amorphous nanocrystalline coating and its preparation method

[0030] A pure aluminum strip of 10×0.3mm (width 10mm, thickness 0.3mm) is selected. Tie it into a U shape first. According to the atomic percentage of each element of the powder core wire material: 13 at. % Si, 7 at. % Ni, 12 at. % Fe, and the balance Al, the ingredients are weighed. Put the taken powder into the powder mixer and mix for 30 minutes, then put the mixed powder into the U-shaped aluminum belt tank, and the filling rate is 37%. Then the U-shaped groove is closed, so that the powder is coated in it, and then the diameter is gradually reduced to Φ2mm through the wire drawing die. The finished wire is wound into a disc shape required by the factory, and after being measured and packaged, it becomes a product that can be shipped. Process parameters used for preparing the coating: the spraying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com