An automated mechanical garage vehicle handling platform

A technology for vehicle handling and mechanical garages, which is applied to buildings where cars are parked, building types, buildings, etc. It can solve problems such as the inability of the pick-and-place mechanism to pick and place low-chassis vehicles, the inconvenience of underground garages, and vehicle damage. Maintenance time, space saving, high clamping force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

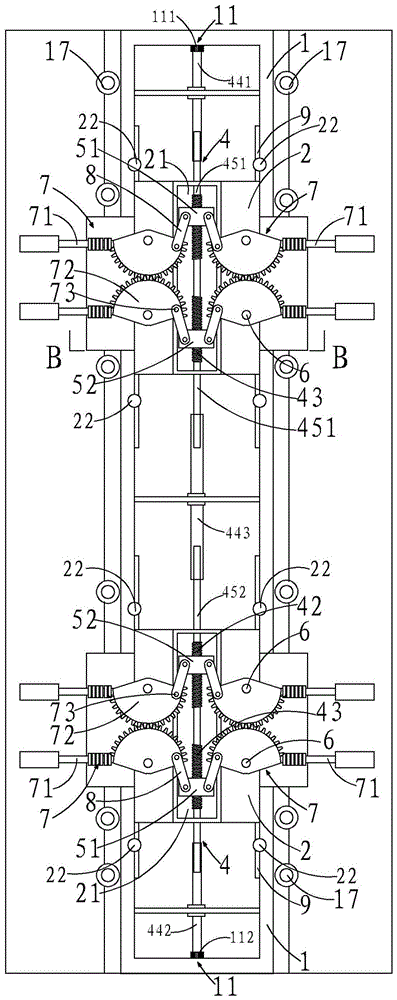

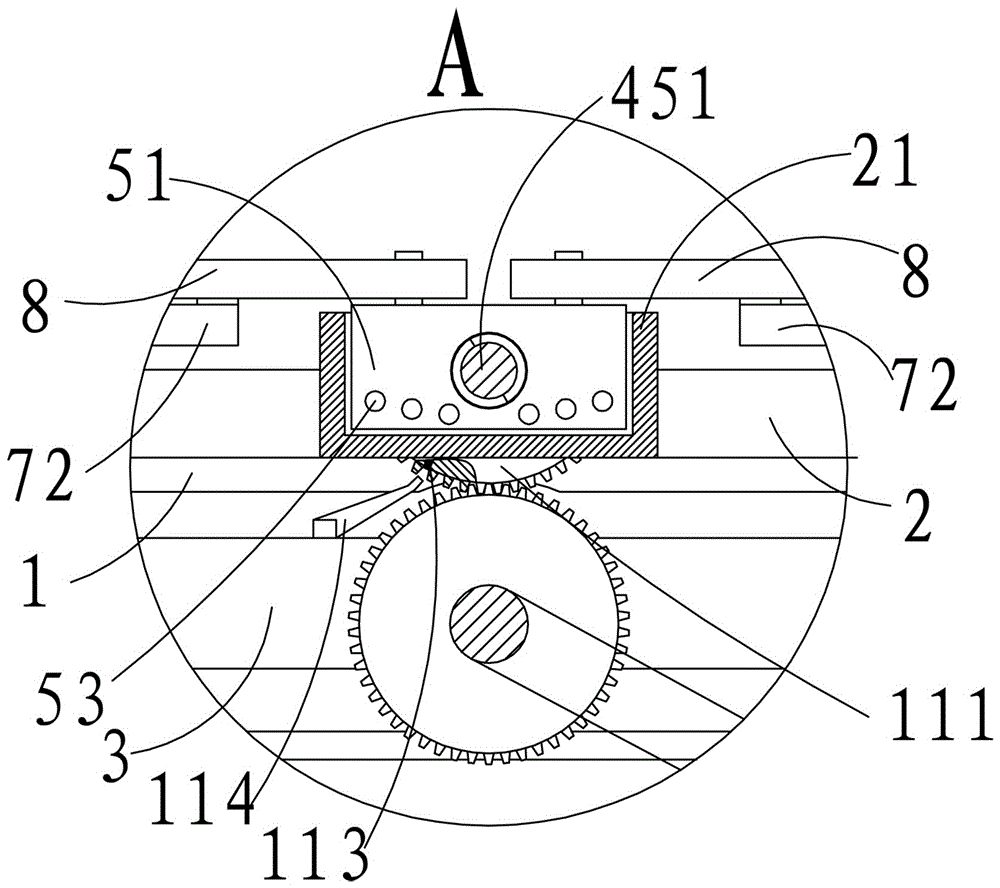

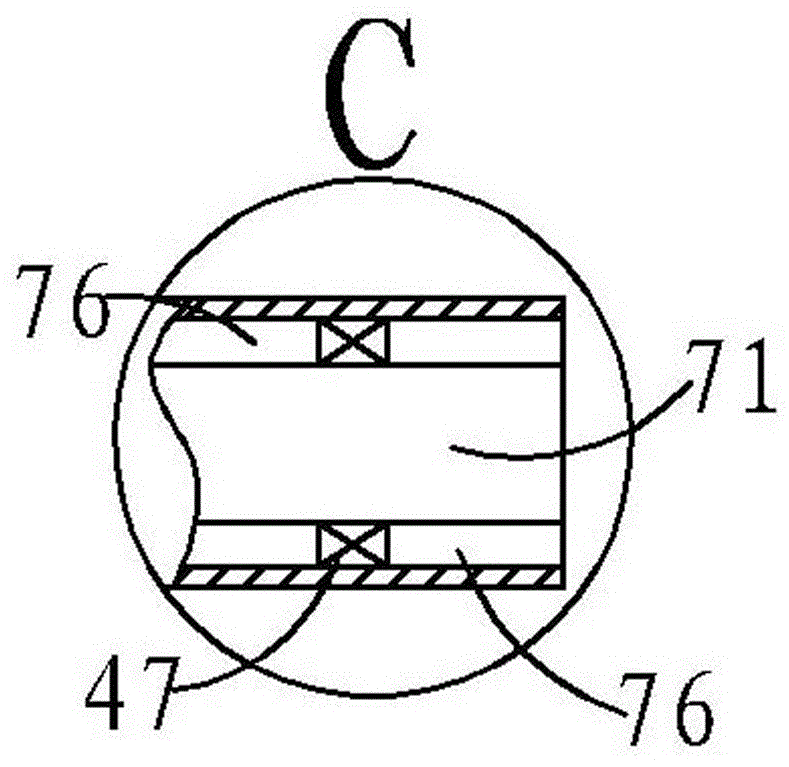

[0042] See attached Figures 1 to 15 , a vehicle handling platform for an automated mechanical garage in this embodiment, including a load-carrying mechanism, a push mechanism, a transmission mechanism and a controller; The two clamping mechanisms on the top, the telescopic shaft 4 connecting two groups of clamping mechanisms in series, the traveling wheels 12 arranged at the bottom of both sides of the upper ring beam 1 along the direction of delivery, and the transmission rack 13 arranged in parallel with the traveling wheels 12 , there are more than two traveling wheels 12 on each side, and the traveling wheels 12 are arranged on the upper ring beam 1 through the traveling shaft 14, and the clamping mechanism includes: Tackle 2, the guide chute 21 that is fixedly arranged on the tackle 2, the slide block 5 that is arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com