Vehicle lifting device for a stereo garage

A technology of a three-dimensional parking garage and a lifting device is applied in the field of vehicle lifting devices for a three-dimensional parking garage, and can solve the problems that a pick-and-place mechanism cannot pick and place a low-chassis vehicle, the underground garage is inconvenient, and the lifting device is difficult, and a simple structure is achieved. Convenience, large clamping force, simple and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

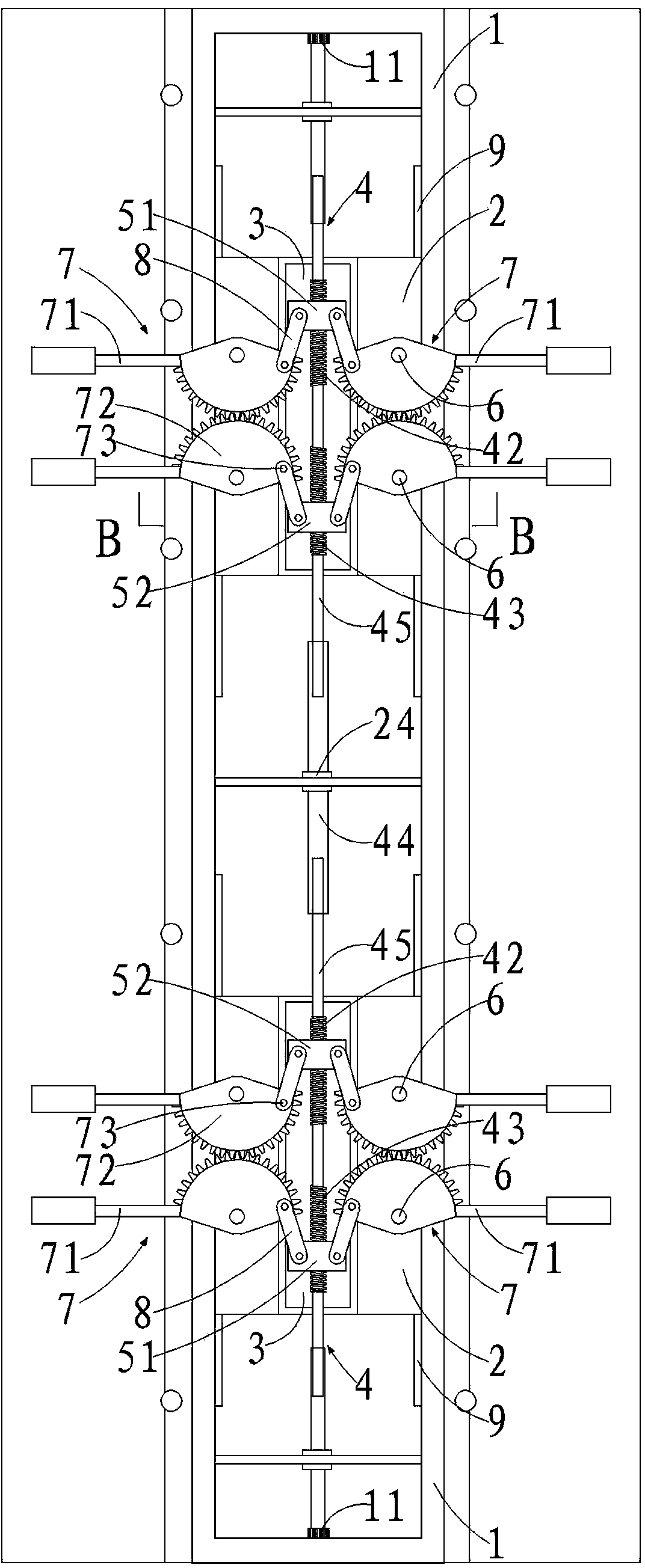

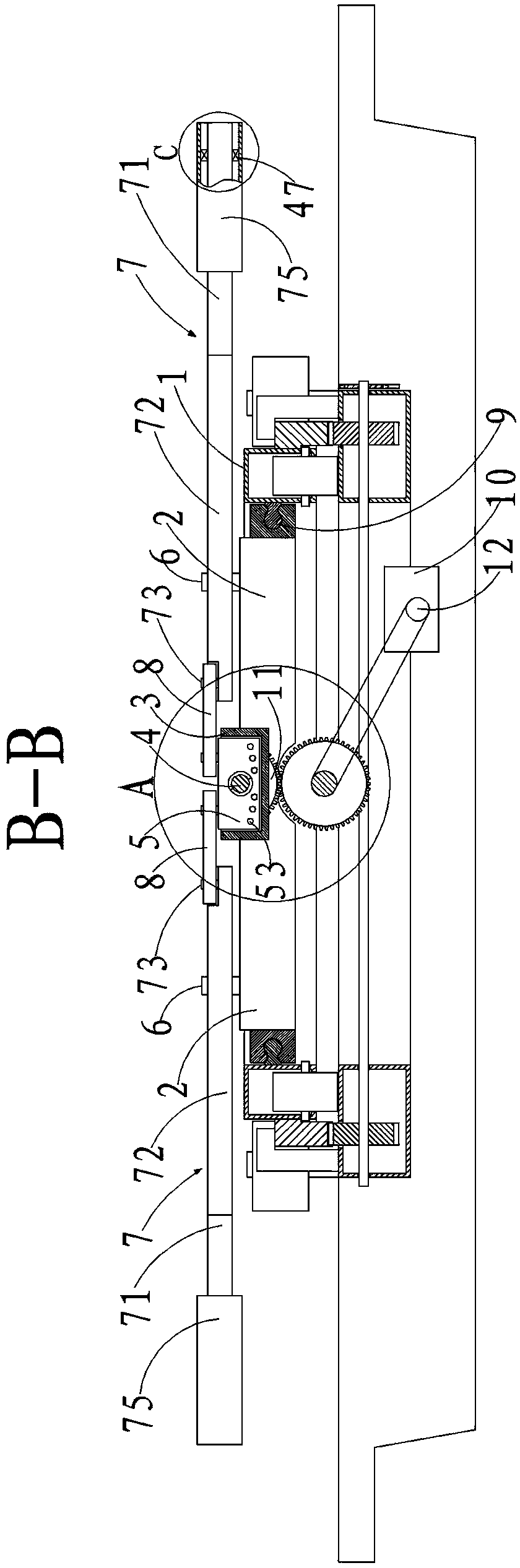

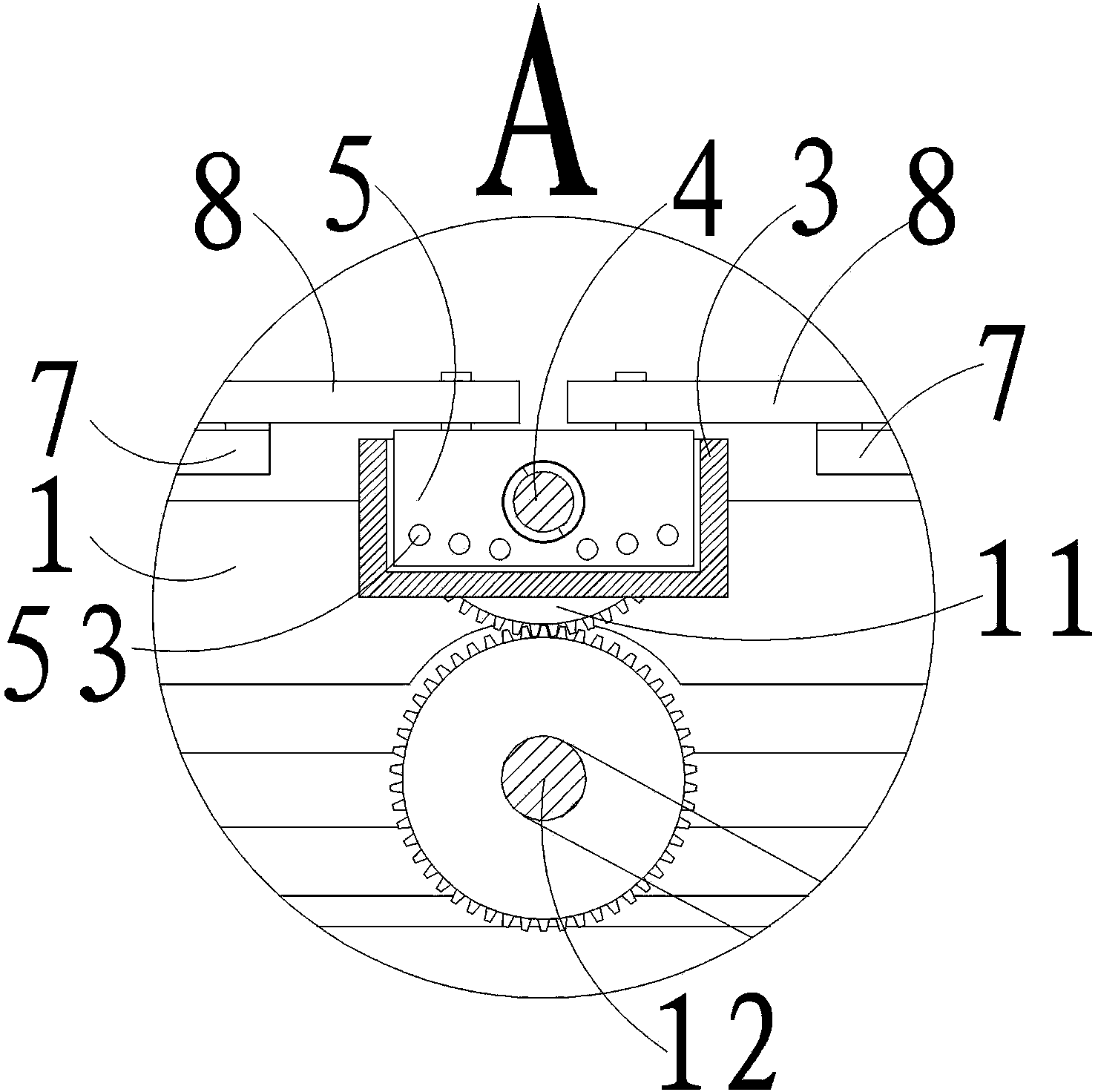

[0031] See attached Figures 1 to 6 , the present embodiment is a kind of three-dimensional parking garage with vehicle clamping lifting device, comprises upper ring beam 1, two clamping mechanisms that are arranged on the upper ring beam 1 by slide rail 9, the telescopic shaft 4 that connects clamping mechanism and with The power output mechanism engaged with the telescopic shaft 4; the clamping mechanism includes: a trolley 2 arranged on the upper ring beam 1 through a slide rail 9, a guide chute 3 fixedly arranged on the trolley 2, and a guide chute 3 fixedly arranged on the trolley 2, and a trolley 3 arranged on the trolley through the telescopic shaft 4. The slide block 5 in the groove 3 and the clamp wheel arms 7 that are arranged in pairs on the pulley 2 by the fixed shaft 6 for lifting the automobile tires, the slide block 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com