Drill pipe automatic discharging system applied to oil field exploitation

An automatic discharge and drill pipe technology, applied in drill pipe, drill pipe, drilling equipment and other directions, can solve the problems of drill pipe clamping, lifting, lowering, translation and rotation not in place, affecting work efficiency, and prone to failure, etc. Achieve good grasping effect, improve work efficiency, and avoid falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

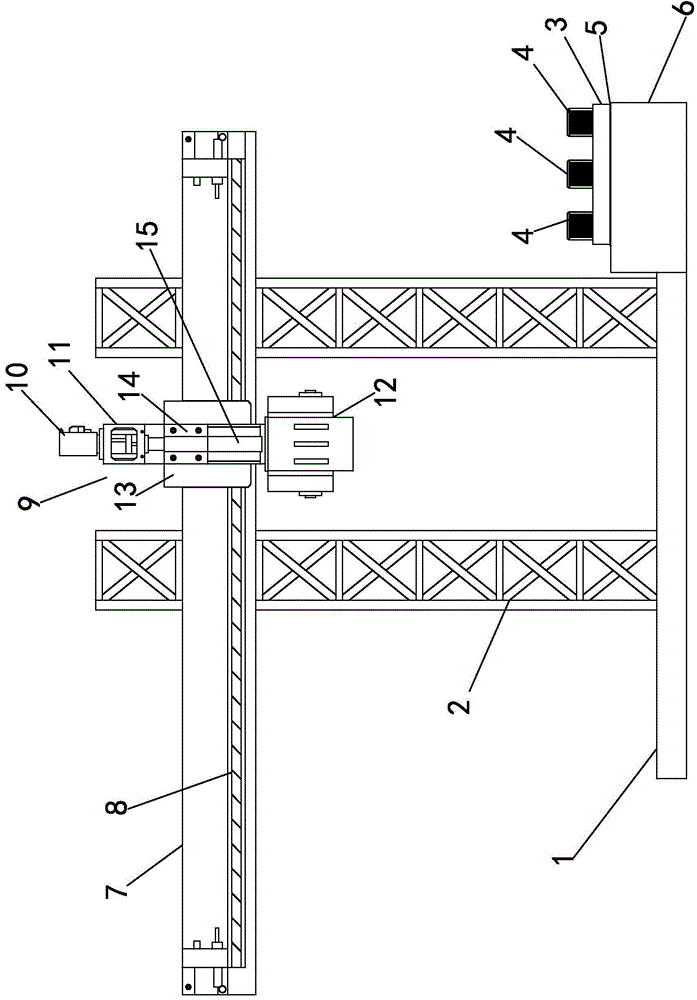

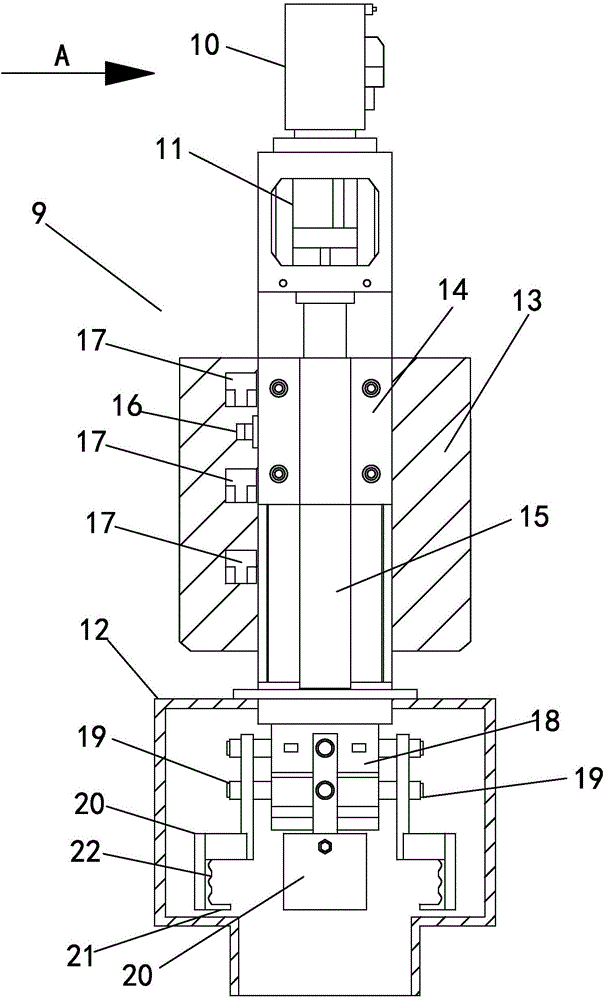

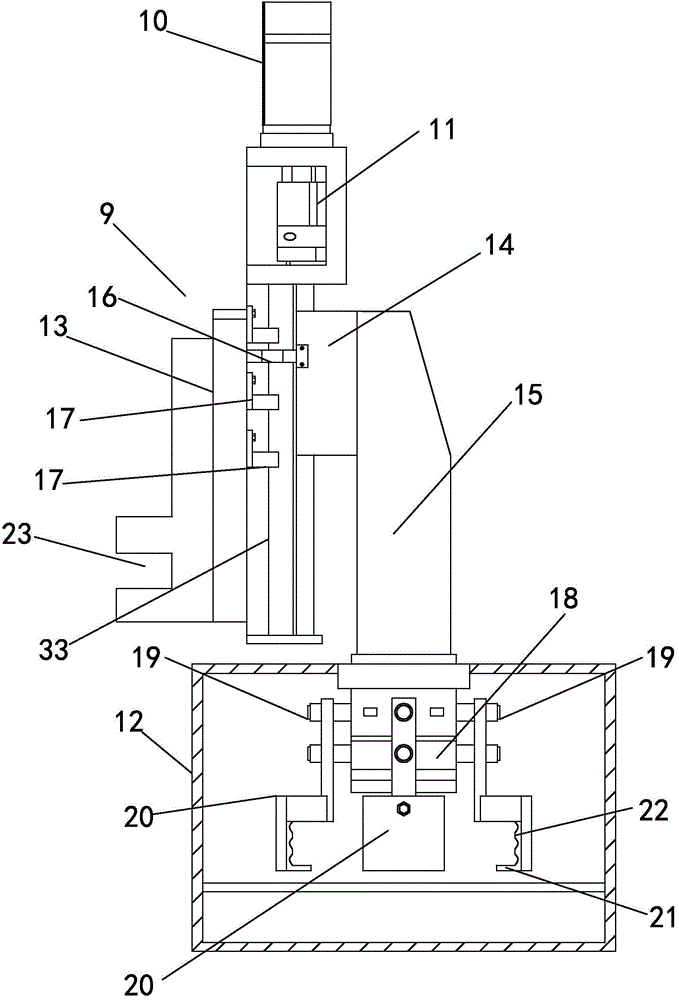

[0027] Figure 1 to Figure 7 As shown, an automatic draining system for drill pipes used in oil fields includes drill pipes 23 , an automatic draining system and a base 1 . The drill pipe 23 is used for excavating boreholes and searching for oil fields. During the drilling process, the drill pipe 23 needs to be moved or replaced frequently, and the automatic discharge system can complete the movement or replacement of the drill pipe 23. The lower end of the drill pipe 23 is provided with an installation collar 24, and the installation collar 24 covers the drill pipe 23. The installation collar 24 is provided with 4 through holes (not marked in the figure), and the 4 through holes are respectively located in the installation sleeve. In the 4 directions of the ring 24, a closed protective cover is embedded in the through hole. The closed protective cover is transparent, and an infrared emitter 25 is arranged in the closed protective cover. When the infrared emitter 25 is opened,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com