Resin mold hardening tunnel kiln car intelligent distribution system

A tunnel kiln and intelligent technology, applied in the field of intelligent distribution system for resin abrasive hardening tunnel kiln car, can solve the problems of low labor productivity, poor production environment, and many human resources, so as to reduce production costs, liberate labor, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

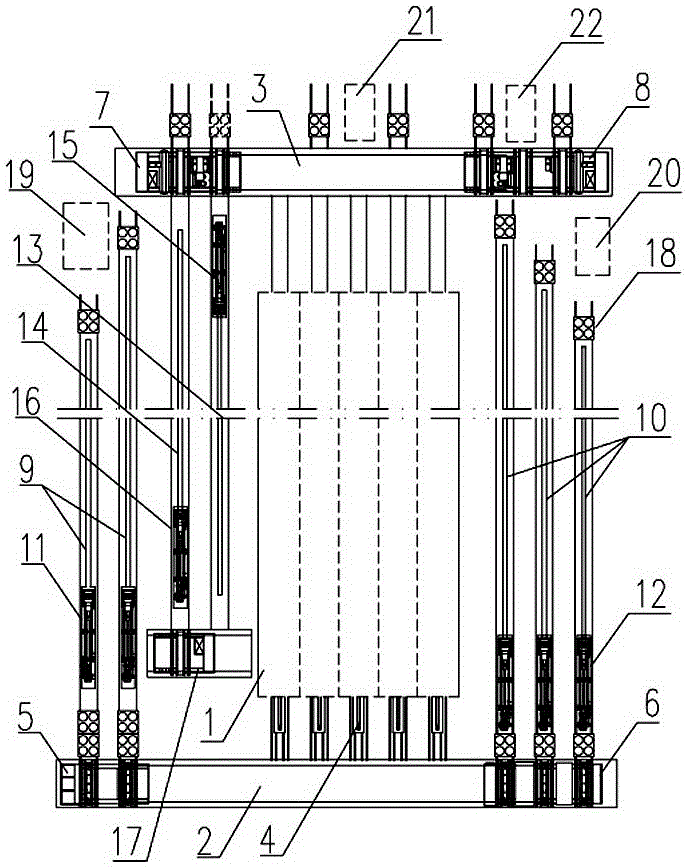

[0009] The present invention is further described below in conjunction with accompanying drawing:

[0010] Such as figure 1 As shown, the intelligent distribution system for resin abrasive hardening tunnel kiln kiln car according to the present invention includes five-channel tunnel kiln 1 arranged side by side, and the kiln head track arranged in the pit on one side of the kiln head of the five-channel tunnel kiln 1 2 and the kiln tail track 3 in the pit on one side of the kiln tail, hydraulic carts 4 are set on the kiln entry track of each channel tunnel kiln; The kiln head transfer vehicles 5 and 6 are provided with a kiln tail transfer vehicle 7 and 8 at the left and right ends of the kiln tail track 3; A plurality of loading rails 9, 10 extending toward the kiln tail direction are arranged side by side at intervals, and each loading rail 9, 10 is provided with a rail loading vehicle 11, 12 driven by a motor to reciprocate along the rail; the kiln tail In the pit at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com