Monitoring method of relative position during butt joint process of large flanges of horizontal vessels

A technology of relative position and large flange, which is applied in the field of monitoring the relative position of the large flange of a horizontal container during the docking process, can solve the problems of lack of monitoring devices for horizontal large flanges and difficulty in grasping the docking accuracy, and achieve convenient measurement, simple structure, and application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

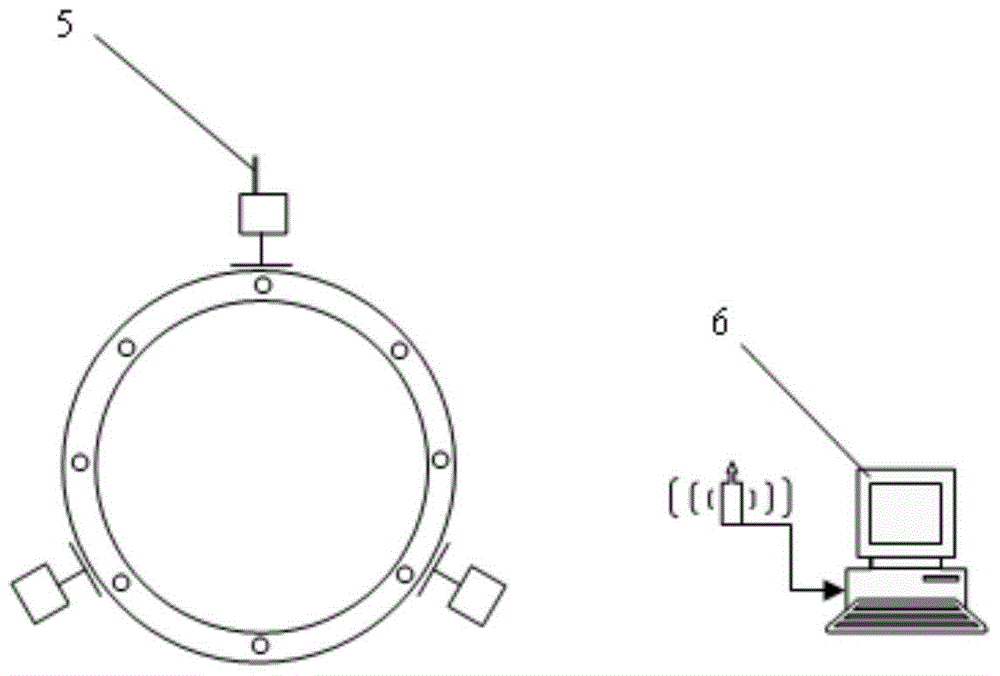

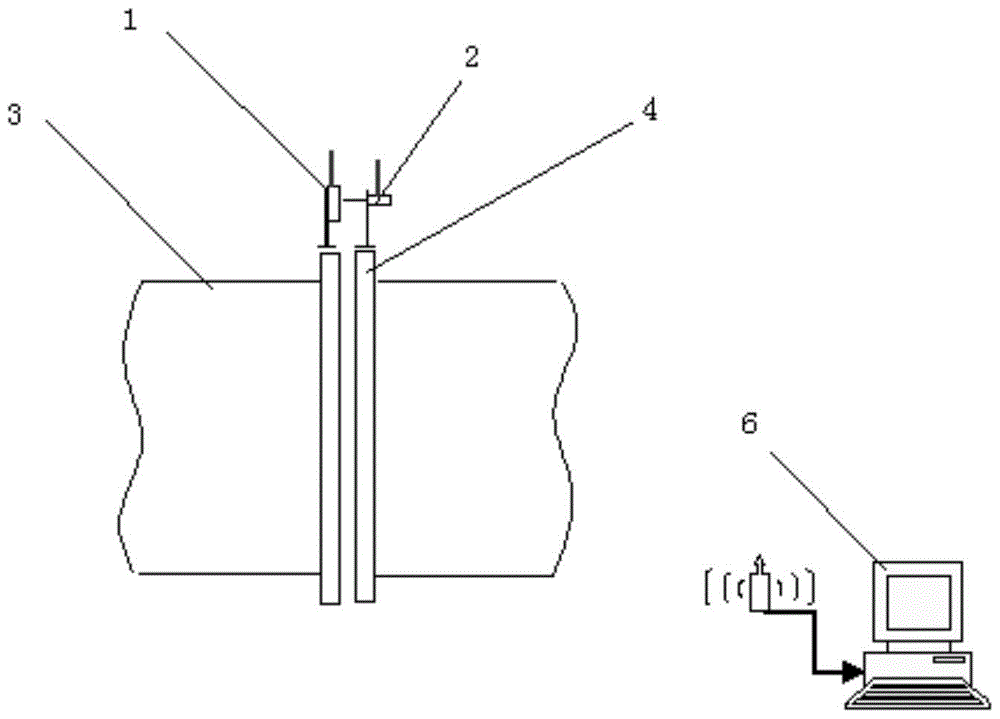

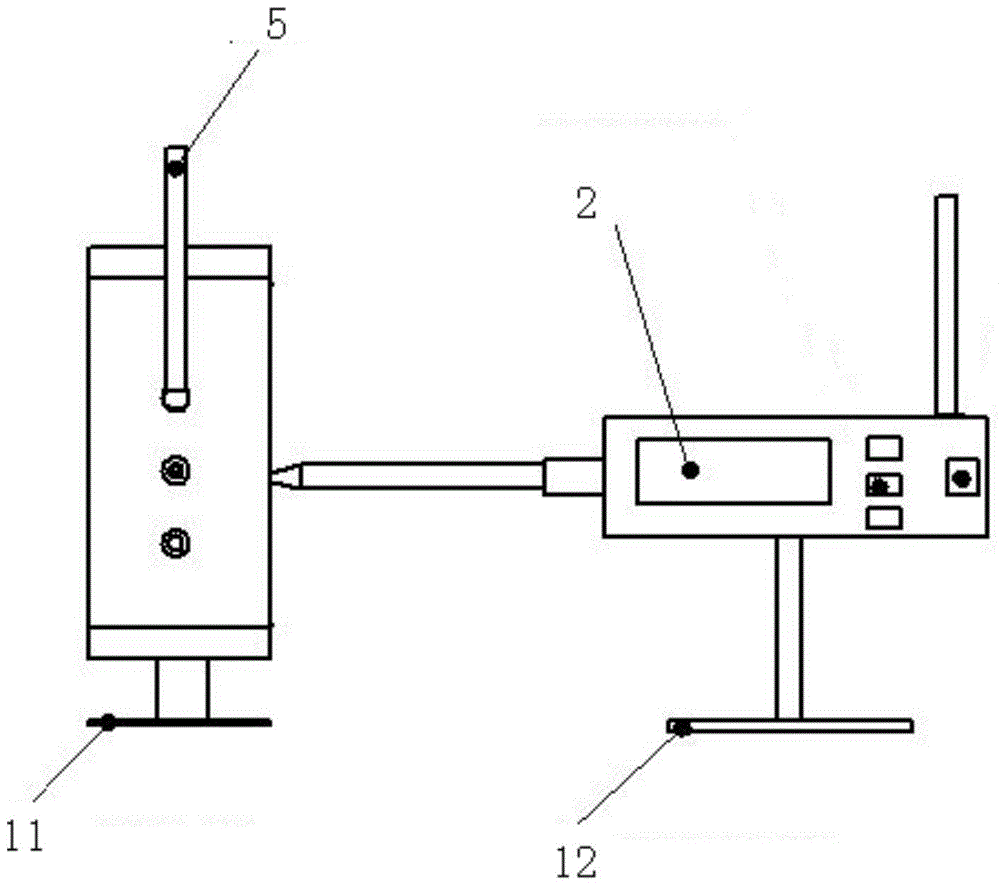

[0061] Example: During the butt joint process of large flanges of a horizontal container, since the flange diameter of the container is 3.2m, two O-shaped rubber sealing rings are installed on the end face of the flange, and the end face of the flange is in a state perpendicular to the ground. If it cannot be accurately docked and placed in place at one time, it will easily cause damage to the rubber sealing ring and rework, and cause time delays in the installation process of super-large equipment, resulting in huge economic losses. In order to avoid the above situation, in the past work, personnel use calipers and board rulers to measure and check. Due to high-altitude operations, inconvenient measurement methods and measurement locations (the measurement location is at a maximum of 4.5m), it is difficult to meet the requirements for measurement efficiency and measurement accuracy. After adopting the technology of the invention, due to the improvement of the measurement meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com