Combustion optimization critical condition determining method on basis of heating furnace combustion model

A technology of combustion model and optimized combustion, which is applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effects of reducing pollution emissions, improving combustion conditions, and avoiding blind adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] A method for determining the optimal combustion edge condition based on the combustion model of the heating furnace of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

[0051] A method for determining the optimal combustion edge condition based on the heating furnace combustion model of the present invention comprises the following steps:

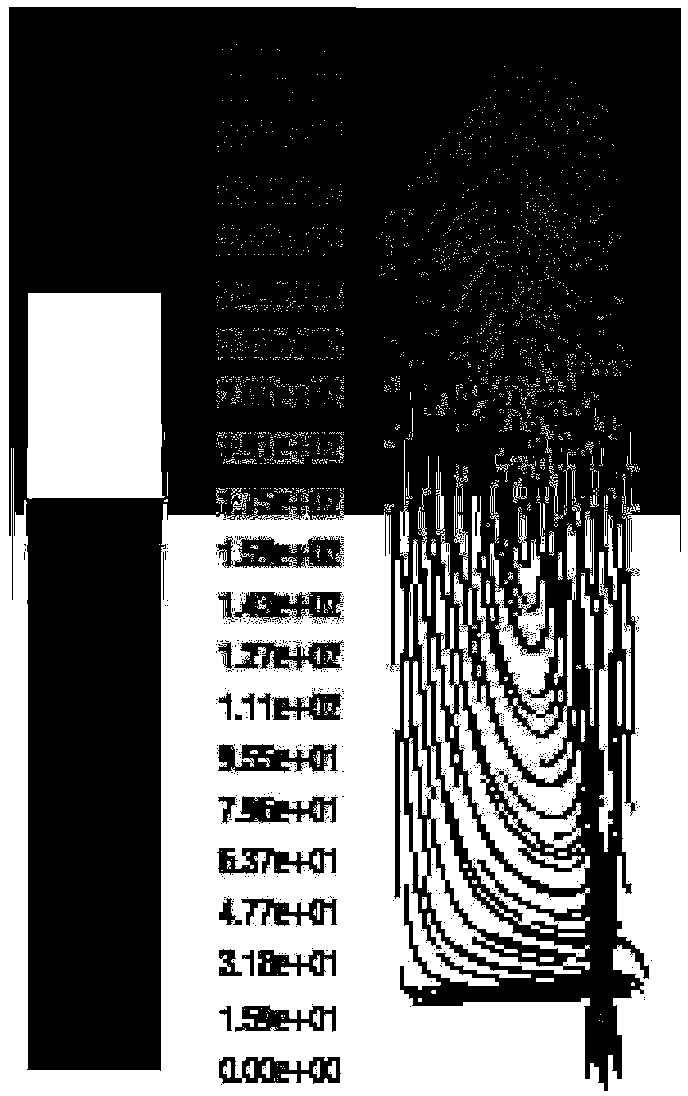

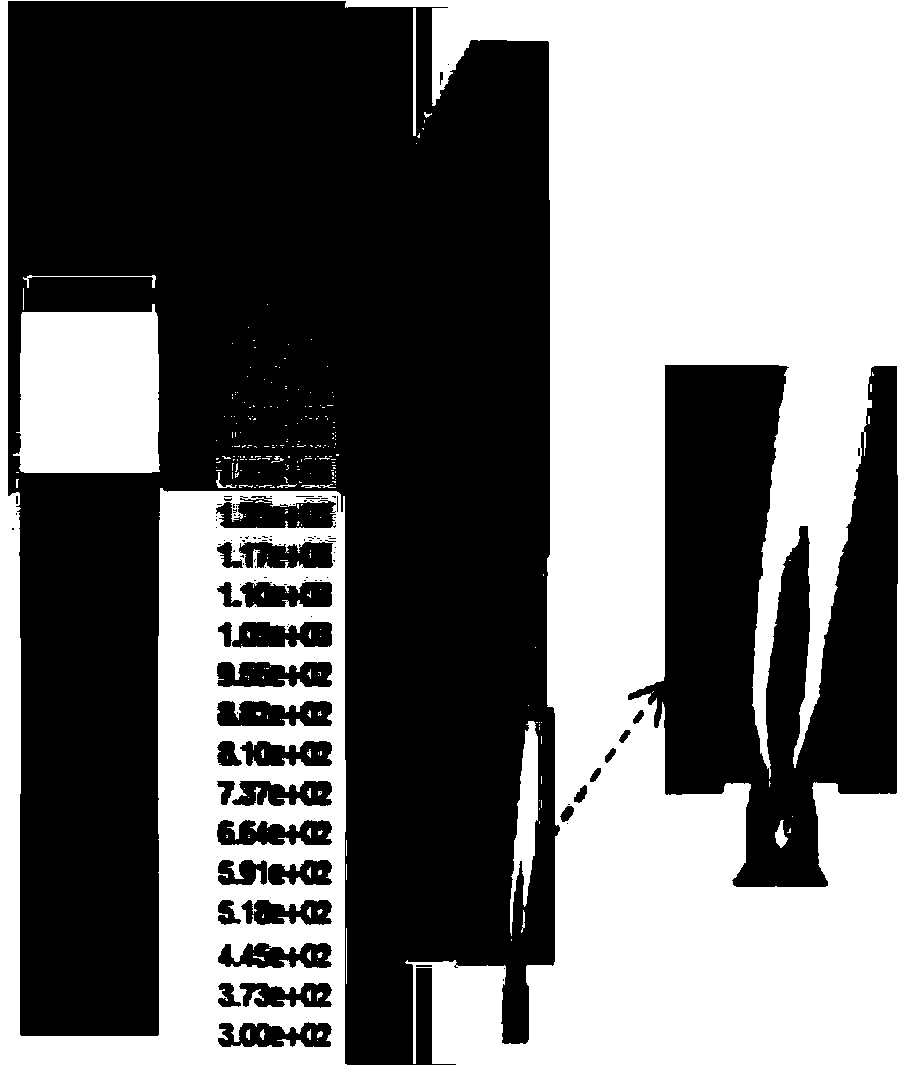

[0052] 1) Use Gambit, the front-end software of FLUENT, to divide the calculation area into meshes, and carry out mesh encryption on the local area of the burner, such as nozzles, fire channels and other parts. Examples of burner mesh division are as follows figure 1 shown. Apply the FLUENT simulation software to establish the combustion model of the heating furnace; the calculation area starts from the gas and combustion air inlet, and connects the furnace above the inlet. In order to reduce the calculation load and improve the calculation efficiency, acco...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap