Method of manufacturing an article

A technology for articles and products, applied in the direction of manufacturing tools, additive manufacturing, process efficiency improvement, etc., to avoid inaccuracies, reduce complexity, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

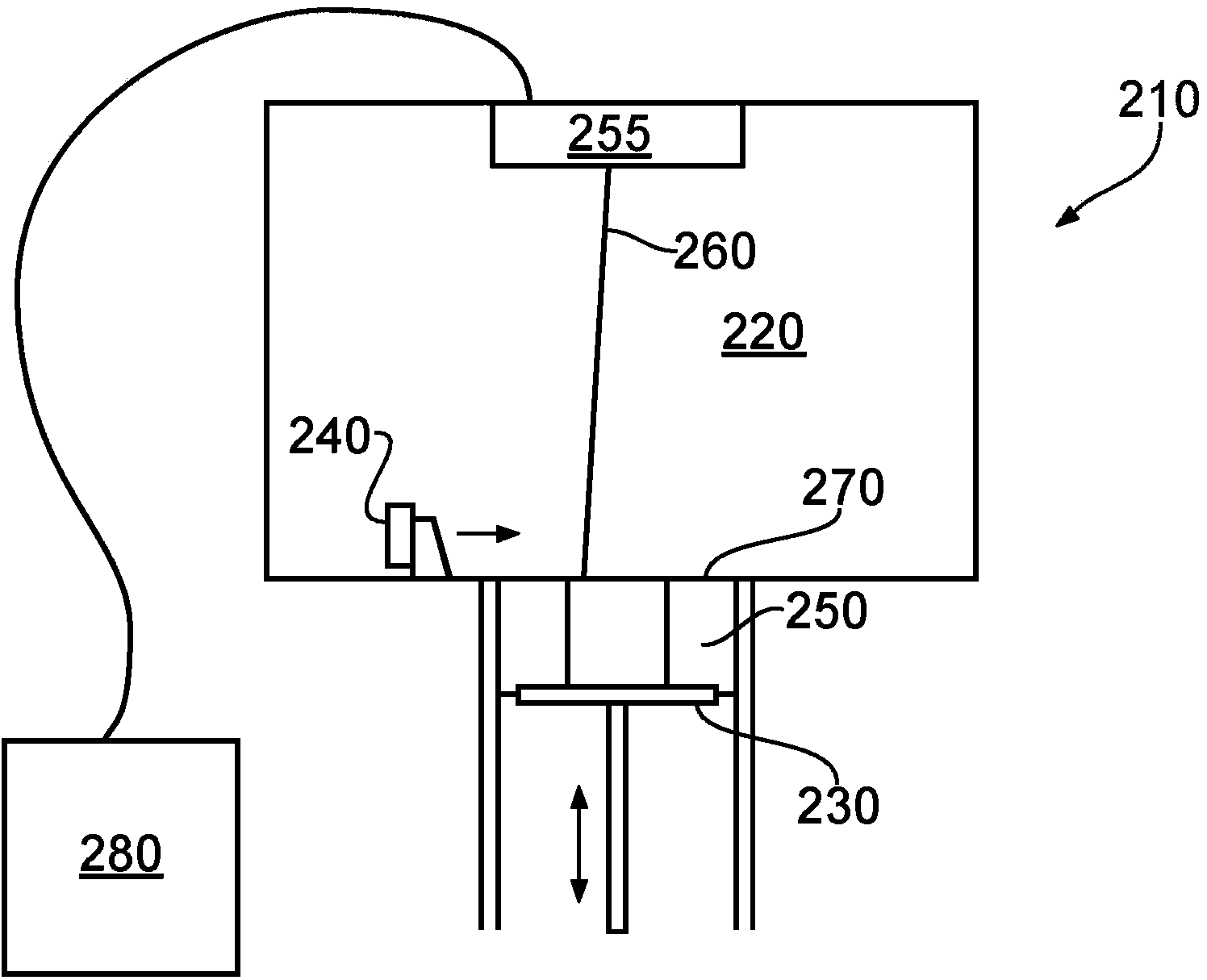

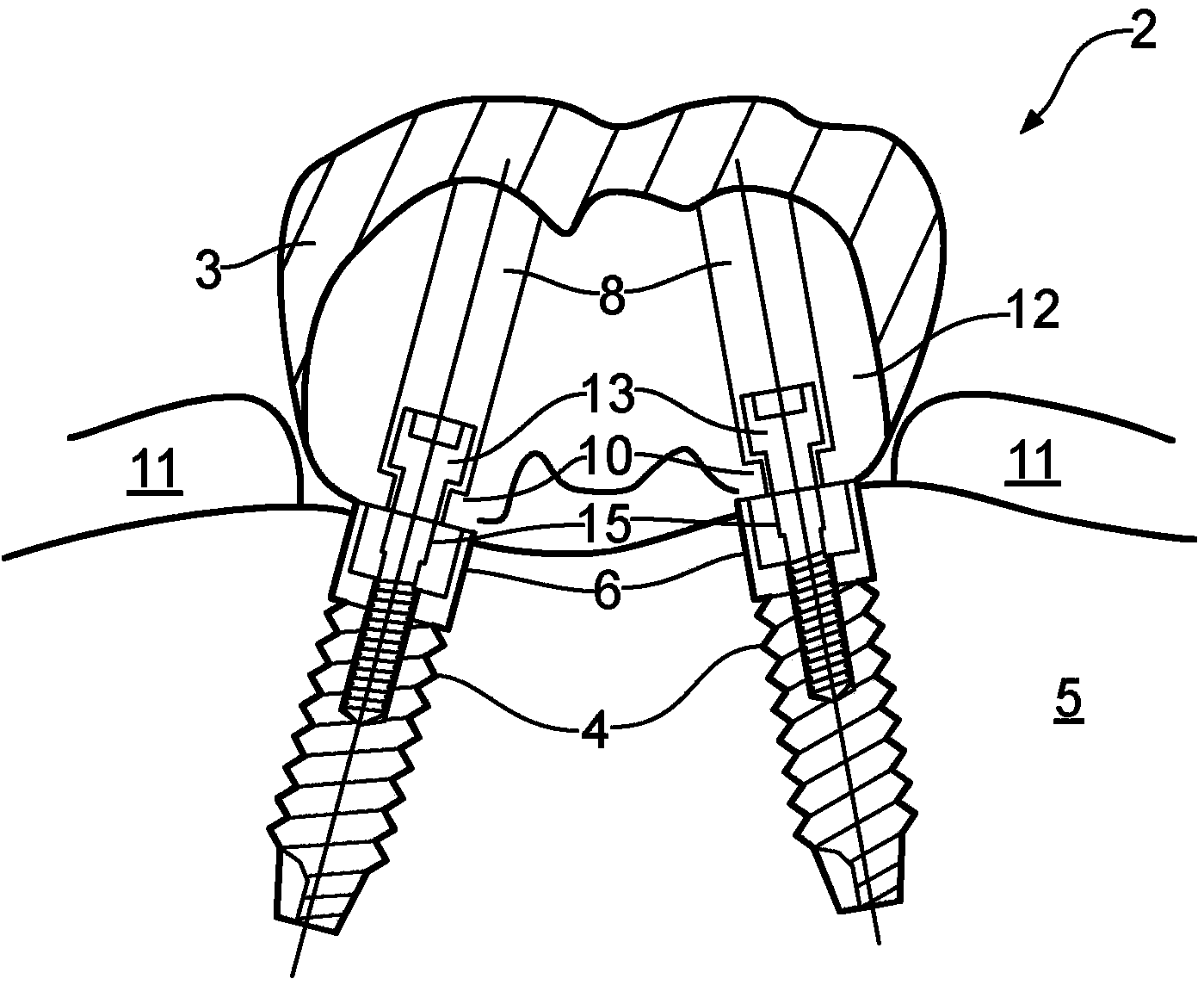

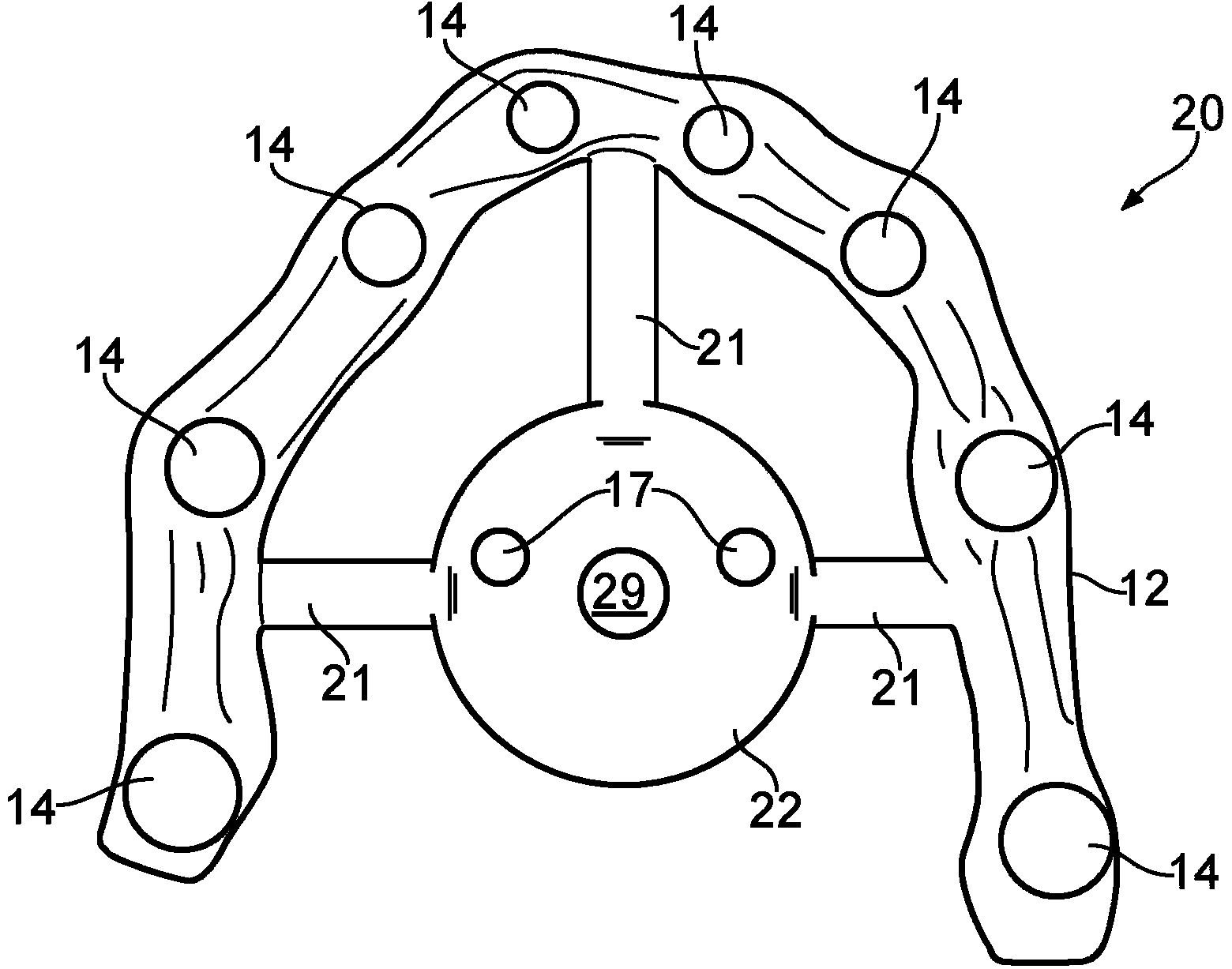

[0076] The following description provides an example of how the invention may be applied to make an implant-supported dental bridge. It should be understood that an implant-supported dental bridge is a specific type of dental restoration which, in use, is secured to a plurality of dental implants already placed in the patient's jaw, thereby retaining the dental restoration in the patient's mouth. Typically, implant-supported bridges are used to replace multiple teeth. Implant-supported bridges are typically made from a metal base structure to which porcelain veneers are added prior to assembly to give the bridge the desired finished shape and appearance. The basic structure of a bridge is often referred to as the "framework" or "superstructure".

[0077] It should be understood that the present invention is not limited to the manufacture of implant-supported bridges, but may also be used, for example, in the manufacture of other types of dental restorations, such as single-to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com