Roof greening frame body and manufacturing method

A roof greening and frame technology, applied in botany equipment and methods, container cultivation, drinking water installations, etc., can solve problems such as moisture leakage on the top surface of the house, increase the load on the roof surface, and difficult to discharge rainwater, etc., to achieve heat preservation The effect is good, the service life is prolonged, and the production method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

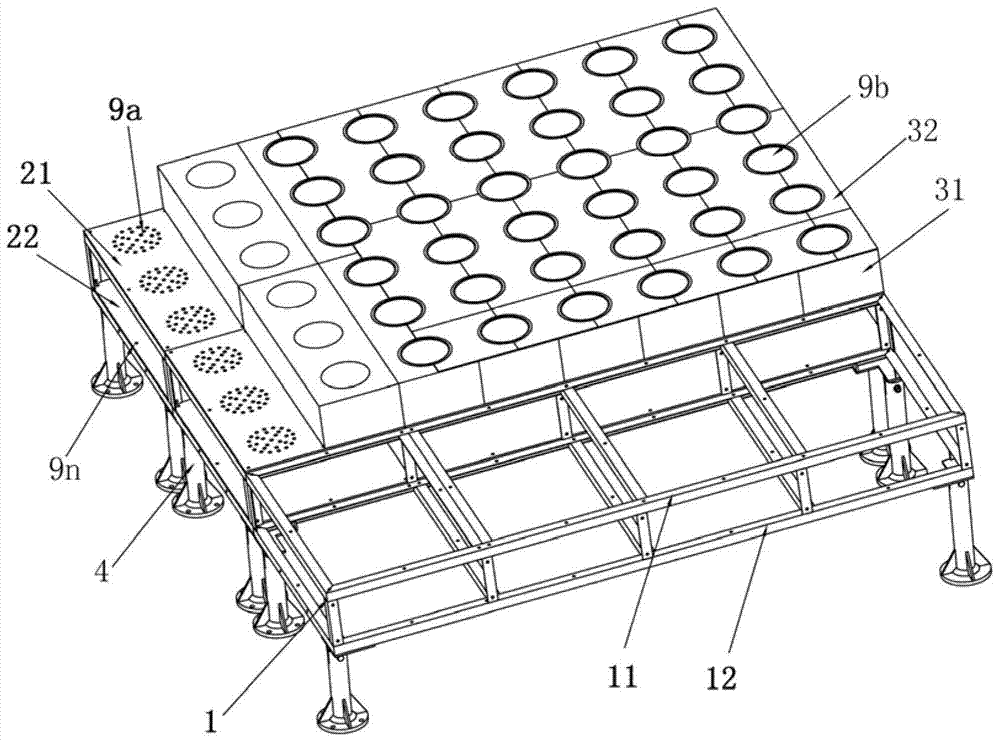

[0055] Such as figure 1 Shown, green roof frame body of the present invention comprises:

[0056] Elevated planting bases placed on the roof;

[0057] The planting insulation layer installed on the elevated planting base;

[0058] A water spraying system installed on the elevated planting base for spraying water to plants planted on the planting insulation layer;

[0059] Wherein, the elevated planting base includes:

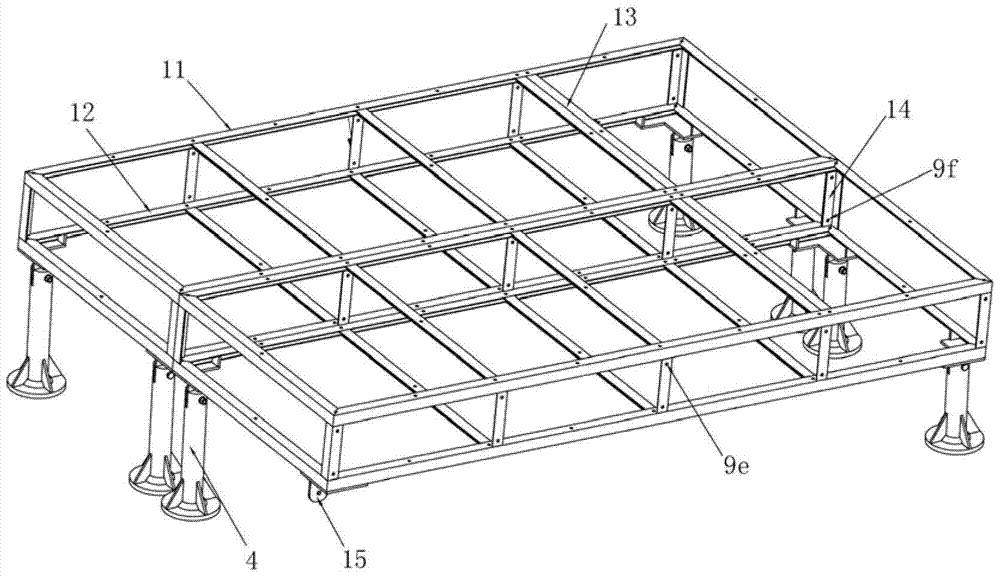

[0060] A shelf frame 1 with an upper frame 11 and a lower frame 12;

[0061] The drainage laminate 21 for drainage installed on the upper frame 11 is provided with a plurality of drainage mesh holes 9a;

[0062] The anti-seepage laminate 22 installed on the lower frame 12 is used to prevent water from penetrating into the roof.

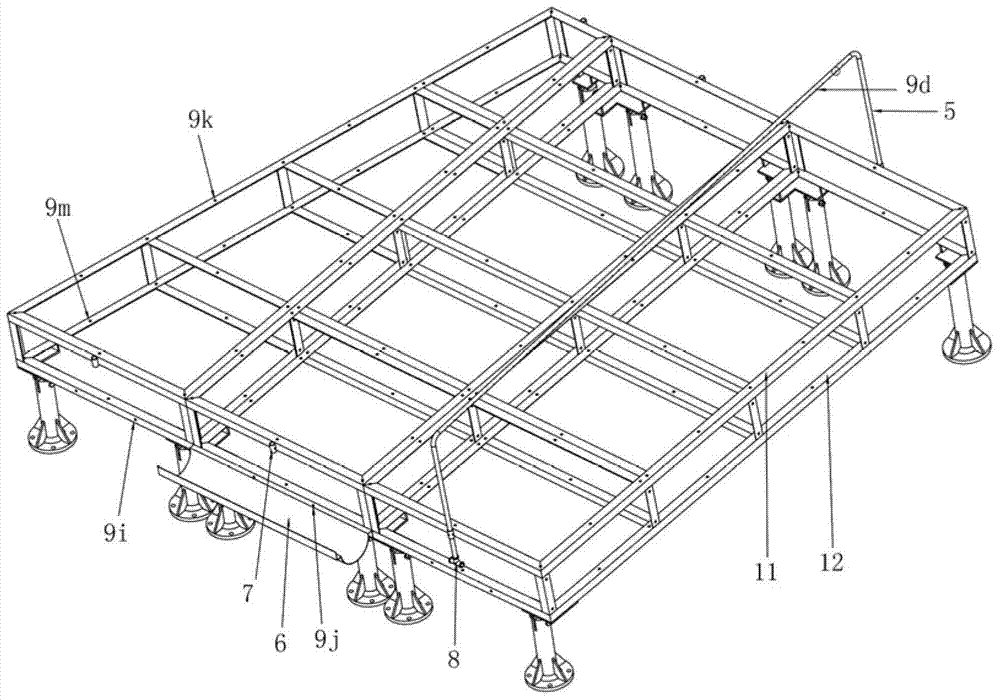

[0063] Referring to Fig. 2, the sprinkler system is fixed on the upper frame 11 and / or the lower frame 12 and includes a plurality of sprinkler pipe racks 5 with elevated sprinkler pipes, and each elevated sprinkler pipe is provide...

no. 2 example

[0073] Figure 6 Another preferred structure of the green roof frame body of the present invention is shown. The difference from the first embodiment is that the protective member 32 is instead made of a plurality of panels with openings corresponding to the openings of the soil cavity 9b, and lacks the different numbers of arc-shaped gaps in the first embodiment. The protective member This design of 32 has the same effect as the design in the first embodiment, but the manufacturing process is different. Of course, the protective member 32 can be designed according to specific conditions, which is flexible and changeable.

[0074] Compared with the first embodiment, this embodiment also lacks the support body 4, and the anti-seepage laminate 22 can be directly placed on the roof and fixed, or a support member of other shapes or structures can be installed at the bottom of the anti-seepage laminate 22 to The anti-seepage laminate 22 is isolated from the roof, which can be spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com