Automatic separating device and method for material receiving of stamping equipment

A stamping equipment and automatic separation technology, applied in the field of stamping equipment, can solve the problems of difficult detection, batch scrapping, and high cost of manual sorting, and achieve the effects of convenient control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

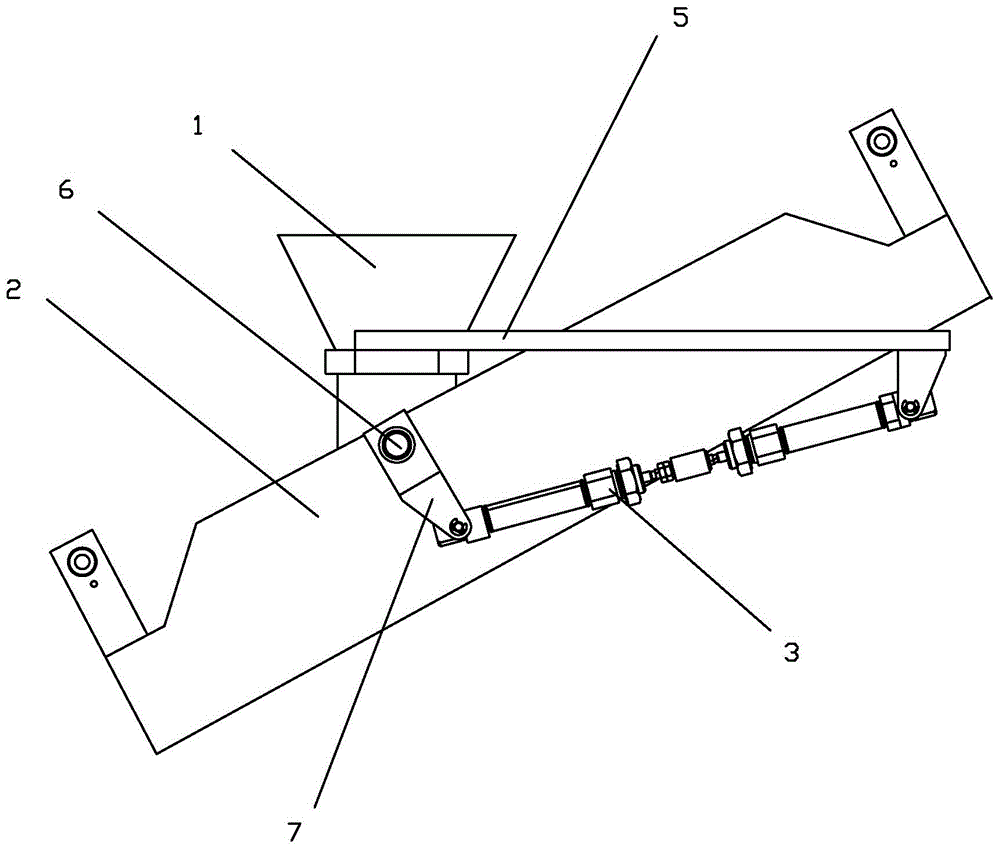

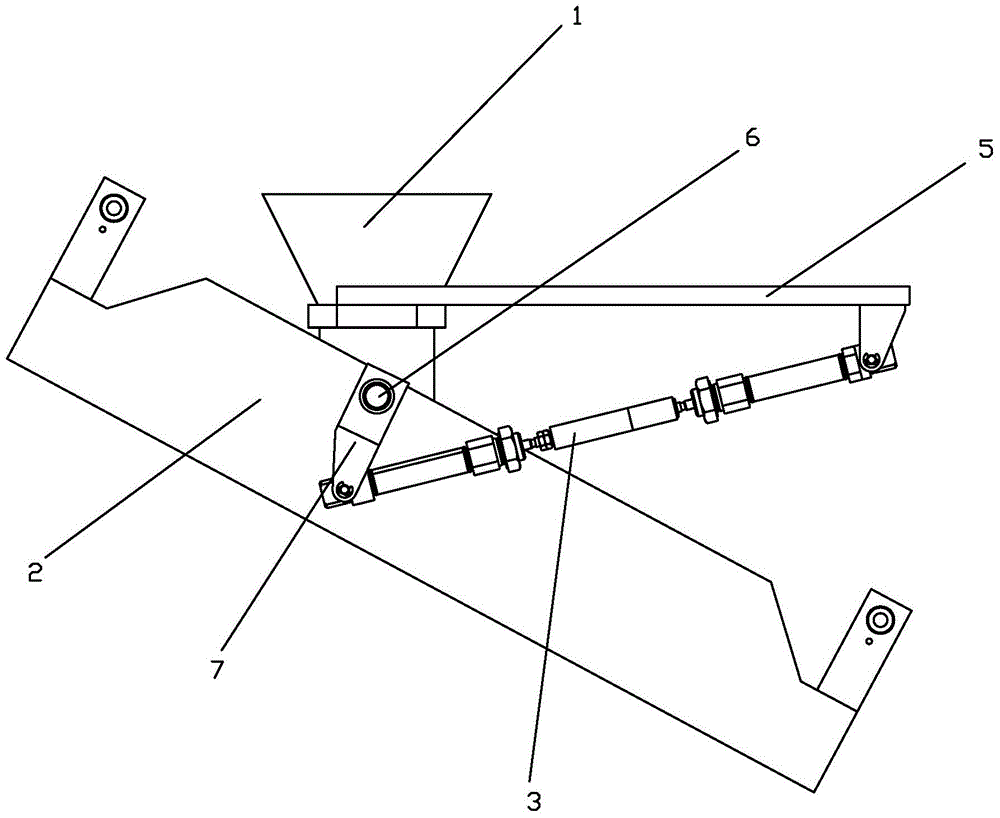

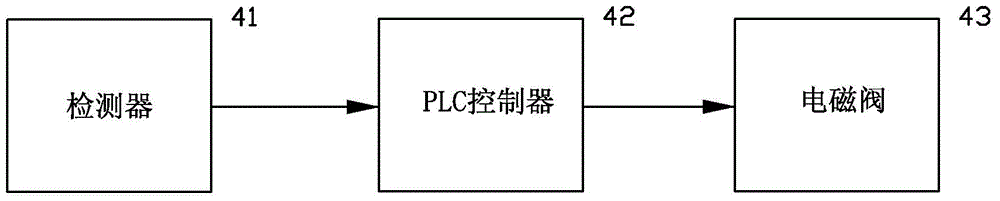

[0023] see Figure 1 to Figure 3 As shown, a material receiving automatic separation device of a stamping equipment of the present invention includes a blanking hopper 1 connected to the end of the material receiving channel of the stamping equipment, a switching tank 2, a material receiving box (not shown in the figure), and a cylinder 3 and circuit control device; the switch slot 2 is connected under the drop hopper 1 in a seesaw manner to accept the parts that come down through the drop hopper 1; the cylinder 3 is connected between the switch slot 2 and the fixed part of the stamping equipment (such as between machines, etc.), the movement of the cylinder 3 drives the switching tank 2 to turn up and down; the two material receiving boxes are respectively arranged under the two ends of the switching tank 2 to receive qualified or unqualified parts; the circuit control device Comprising a detector 41, a PLC controller 42 and an electromagnetic valve 43 used to control the gas...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap