A turntable defective product repair system

A repair system, turntable technology, applied in the direction of additive manufacturing, coating device, 3D object support structure, etc., can solve the problems of one-time forming workpiece repair technology, waste of time, process raw materials, and difficulty in reaching a percent pass rate Hundreds of problems, to achieve the effect of reducing occupied space, improving efficiency and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

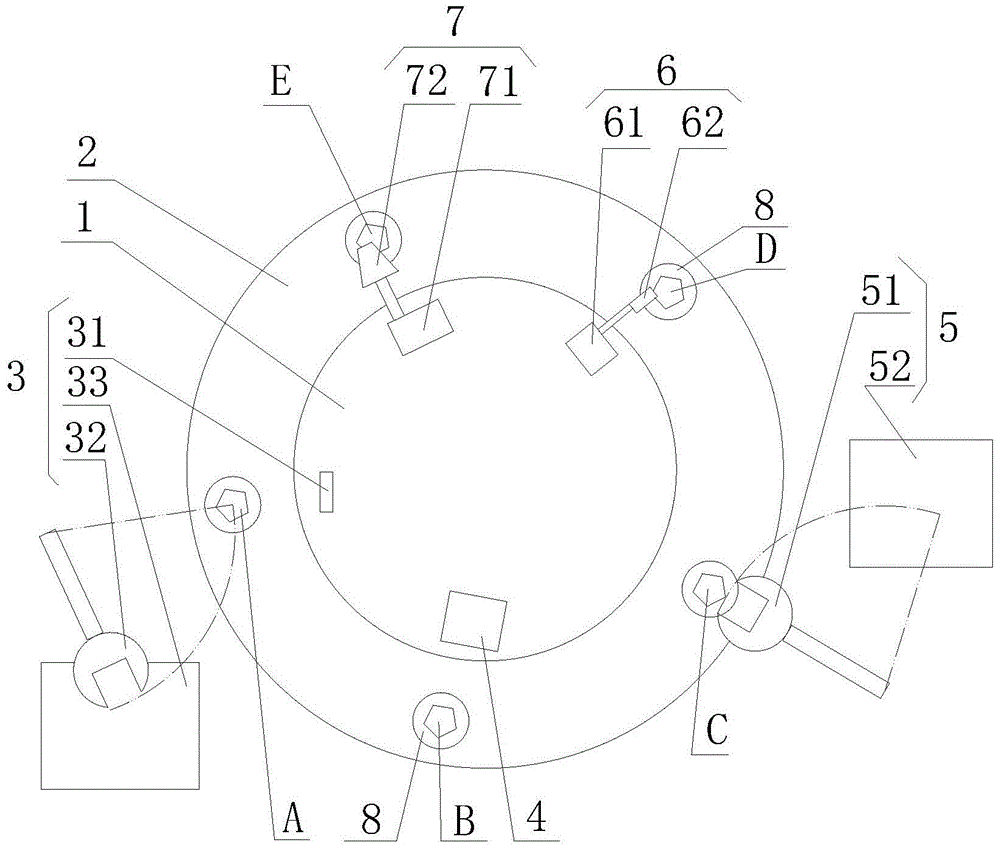

[0022] refer to figure 1 , a turntable defective product repair system proposed by the present invention, including: a center plate 1, a turntable 2, a loading module 3, a scanner 4, a blanking module 5, a cutting module 6, a printing module 7 and a control processing module.

[0023] The turntable 2 is rotatably installed on the outer periphery of the center disk 1 and coincides with the central axis of the center disk 1; N rotatably mounted worktables 8 are evenly distributed along the circumference of the turntable 2, N=1, and the workbench 8 is used to carry artifact.

[0024] The loading module 3 includes a material detection sensor 31 , a first clamping member 32 and a first material box 33 . The material detection sensor 31 is used to detect whether there is a workpiece on the workbench 8 , and the first clamping member 32 is installed on the outside of the turntable 2 and can be connected to the first material box 33 . The first clamping part 32 works following the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com