Automatic encasement device for products contained in cups

An automatic packing and product technology, applied in the direction of automatic packaging control, packaging, packaging protection, etc., can solve the problems of low production efficiency and low degree of automation, and achieve the effect of improving speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

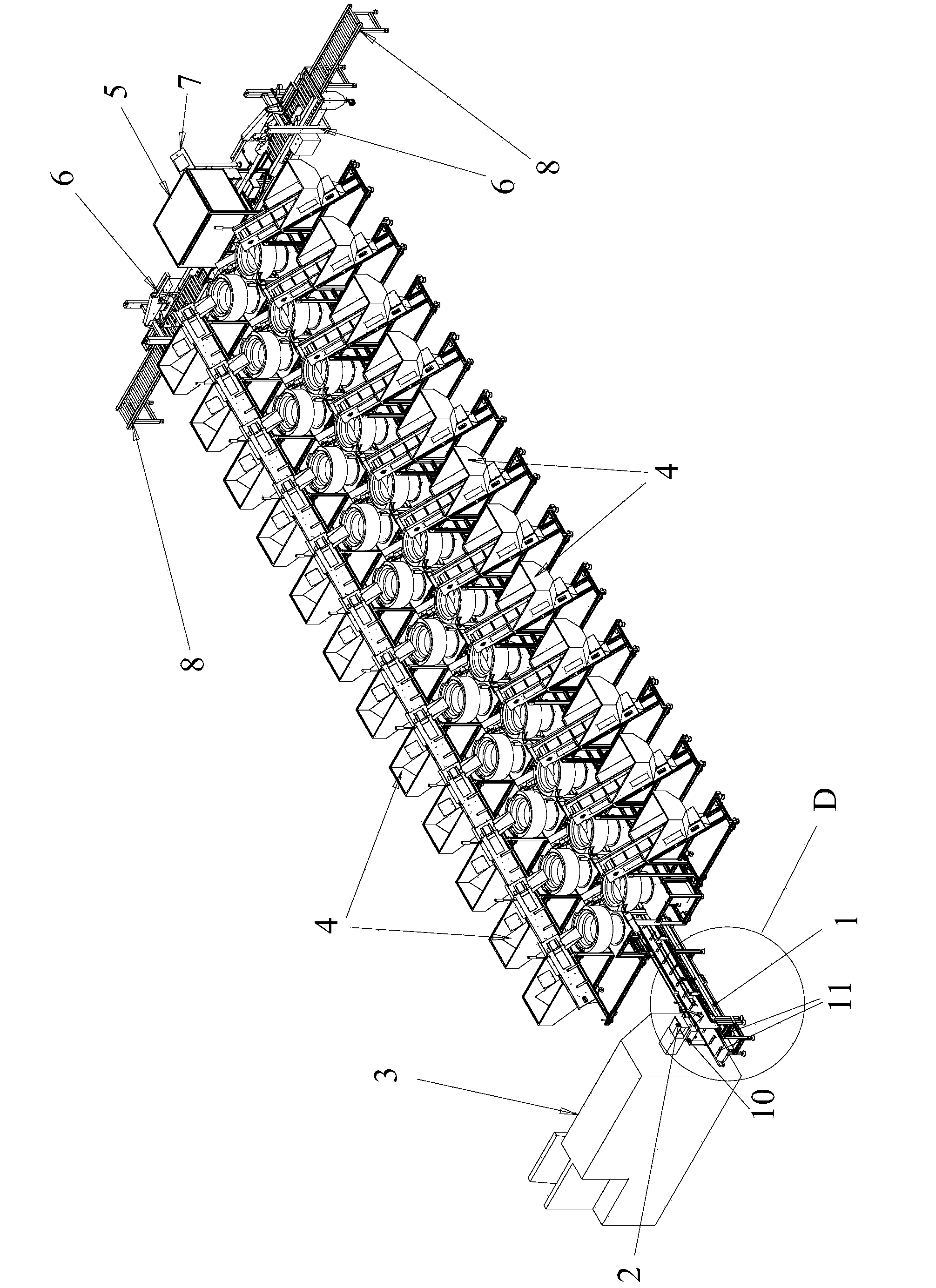

[0046] In this embodiment, 12 cup-packed product automatic boxing mechanisms are provided on both sides of the transmission mechanism as an example to describe the following.

[0047] like Figures 1 to 9 As shown, the cup-packed product automatic boxing equipment of the present invention is used to carry out statistics and pack the cup-packed product into the box; it includes:

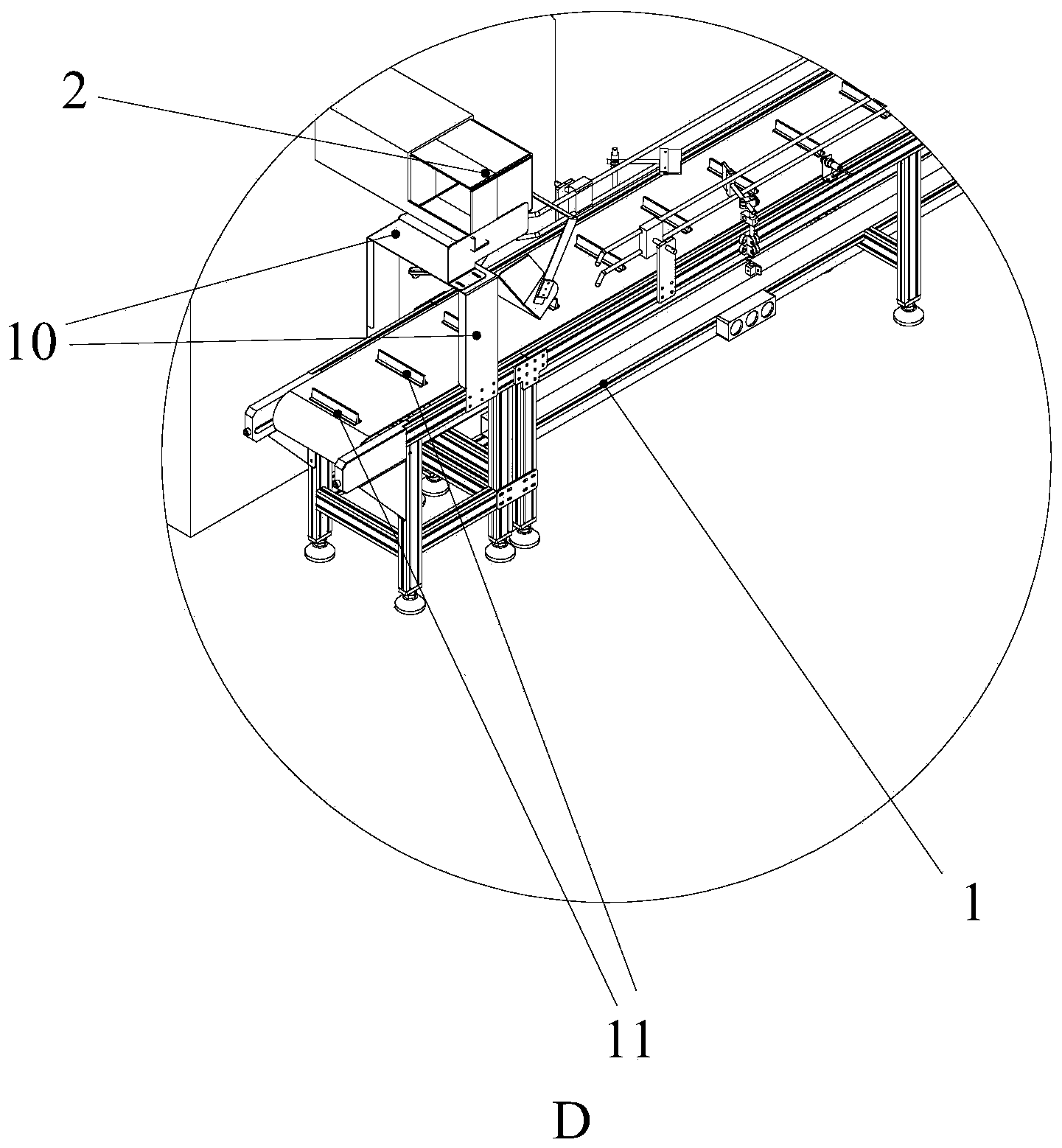

[0048] The transmission mechanism 1 is used to transmit the box body 2 to realize the box body to undertake the cup-packed product 9;

[0049] Be arranged on the unpacking mechanism 3 of conveying mechanism 1 head end, this unpacking mechanism 3 docks with the head end of conveying mechanism 1; Carry out unpacking and forming. The unpacking mechanism 3 is characterized in that it can realize a high-speed unpacking speed of 25 boxes 2 per second, which can realize fully automatic unpacking and achieve the effect of saving time and labor;

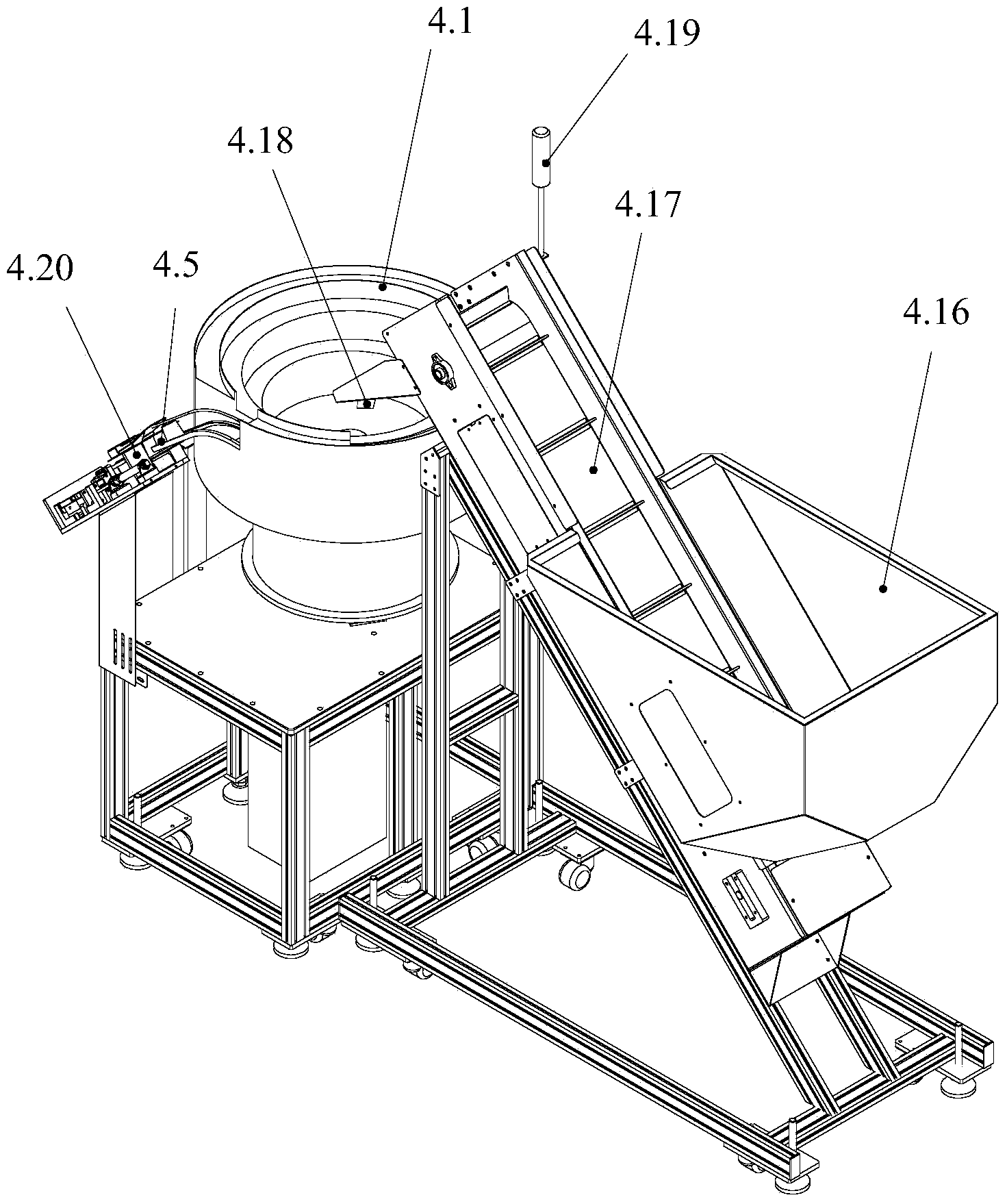

[0050] 24 cup-packed product automatic boxing mechanisms 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com