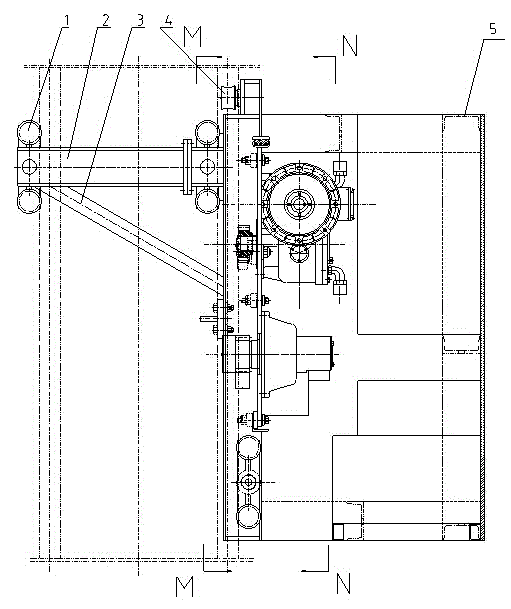

Dual-braking transmission mechanism of construction hoist

A technology for construction elevators and transmission mechanisms, which is applied in elevators, electromechanical devices, and electric components, etc., can solve the problems of insufficient safety performance of construction elevator transmission mechanisms, fault-free protection and control, inoperable transmission mechanisms, and poor safety and reliability. Safe and reliable operation, avoiding the expansion or deterioration of faults, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

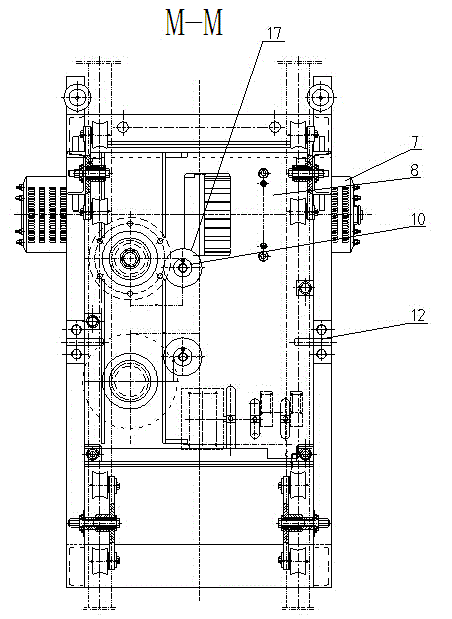

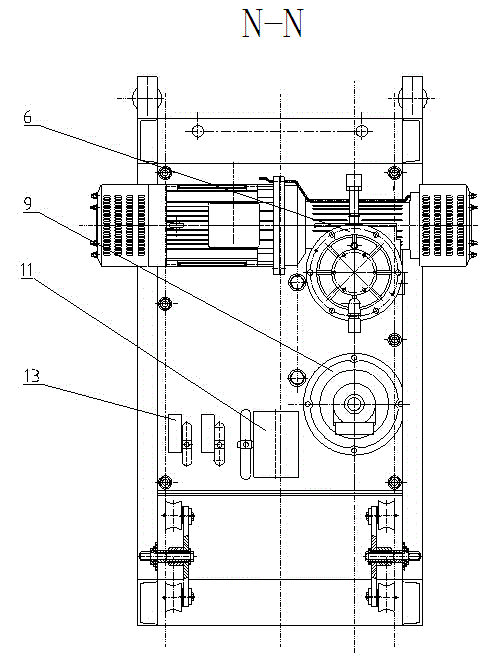

[0042] Figure 5 Shown is the double-brake gear reduction two transmission mechanism, with two sets of double-brake power units as the core components installed on the drive mounting plate, when the special motor for the construction hoist drives the gear reducer 61, the gear reducer 61 is a helical bevel gear reducer or helical gear reducer, figure 1 The side guide wheels in refer to the Figure 5 The upper side guide wheel 41 and the lower side guide wheel 42 in.

Embodiment 2

[0044] Figure 6 Shown is the two-brake worm gear reduction transmission mechanism. Two groups of double braking power units are installed on the drive mounting plate as the core components, when the special motor for the construction hoist drives the worm gear reducer 62.

[0045] Figure 7 Shown is a dual brake gear reduction single drive. A set of double brake power unit is installed on the drive mounting plate as the core component, and the rest of the structure is the same as the double brake gear reduction two transmission mechanism.

[0046] Figure 8 Shown is a double brake worm gear reduction single drive. A set of double brake power unit is installed on the drive mounting plate as the core component, and the rest of the structure is the same as the double brake worm gear reduction two transmission mechanism.

[0047] Such as Figure 9a and 9b The double-brake gear reduction power unit shown is composed of five parts: motor, gear reducer, primary brake, special...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com