Preparation method for hyperbranched polycarboxylic-acid concrete efficient water reducer

A high-efficiency water reducer and polycarboxylic acid technology, applied in the field of concrete admixtures, can solve the problems of limited cement dispersion effect, small slump loss, insufficient viscosity reduction effect, etc., to achieve small slump loss and low production cost , The effect of convenient solvent recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

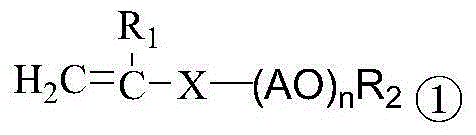

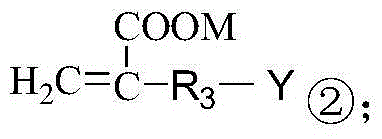

Problems solved by technology

Method used

Image

Examples

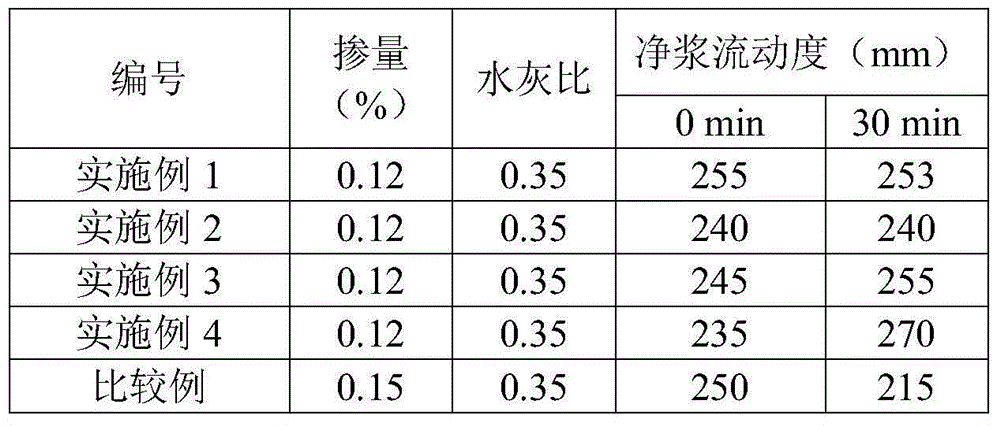

Embodiment 1

[0044] After fully mixing 48g of polyethylene glycol acrylate (Mn=480g / mol), 49.5g of alkali-neutralized 2-bromomethacrylic acid, 2.87g of cuprous bromide, 6.25g of bipyridyl, 73g of methanol and 73g of water , into N 2 O in the solution 2 discharge, the N 2 Self-condensation vinyl polymerization was carried out under protection, the reaction temperature was 40° C., and the reaction time was 8 hours to obtain a hyperbranched polymer solution. The solvent was removed by rotary evaporation to obtain a hyperbranched polymer with a molecular weight of 17476.

Embodiment 2

[0046] 240g monomer methallyl polyglycol ether (Mn=2400g / mol), 120.5g alkali-neutralized 2-(4-(bromomethyl)phenyl)acrylic acid and 5.74g cuprous bromide , 10.97g three (2-dimethylaminoethyl) amine, 240g toluene fully mixed, pass into N 2 O in the solution 2 discharge, the N 2 Self-condensation vinyl polymerization was carried out under protection, the reaction temperature was 100° C., and the reaction time was 16 hours to obtain a hyperbranched polymer solution. The solvent was removed by rotary evaporation to obtain a hyperbranched polymer with a molecular weight of 35114.

Embodiment 3

[0048] 95g monomer polyethylene glycol methyl ether methacrylate (Mn=950g / mol), 71.6g alkali-neutralized 3-bromo-2-methylenebutanoic acid and 1.02g cuprous bromide, 2.48g After pentamethyldiethylenetriamine, 155.5g methanol and 233g water are fully mixed, N 2 O in the solution 2 discharge, the N 2 Self-condensation vinyl polymerization was carried out under protection, the reaction temperature was 30° C., and the reaction time was 10 h to obtain a hyperbranched polymer solution. The solvent was removed by rotary evaporation to obtain a hyperbranched polymer with a molecular weight of 59877.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com