Preparation method of controllable-composition polyoxyethylene sorbitol (sorbitan) fatty acid ester

A technology of sorbitan and polyoxyethylene, which is applied in the field of preparation of polyoxyethylene sorbitan fatty acid esters, can solve problems such as incomplete preparation, and achieve stable quality and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

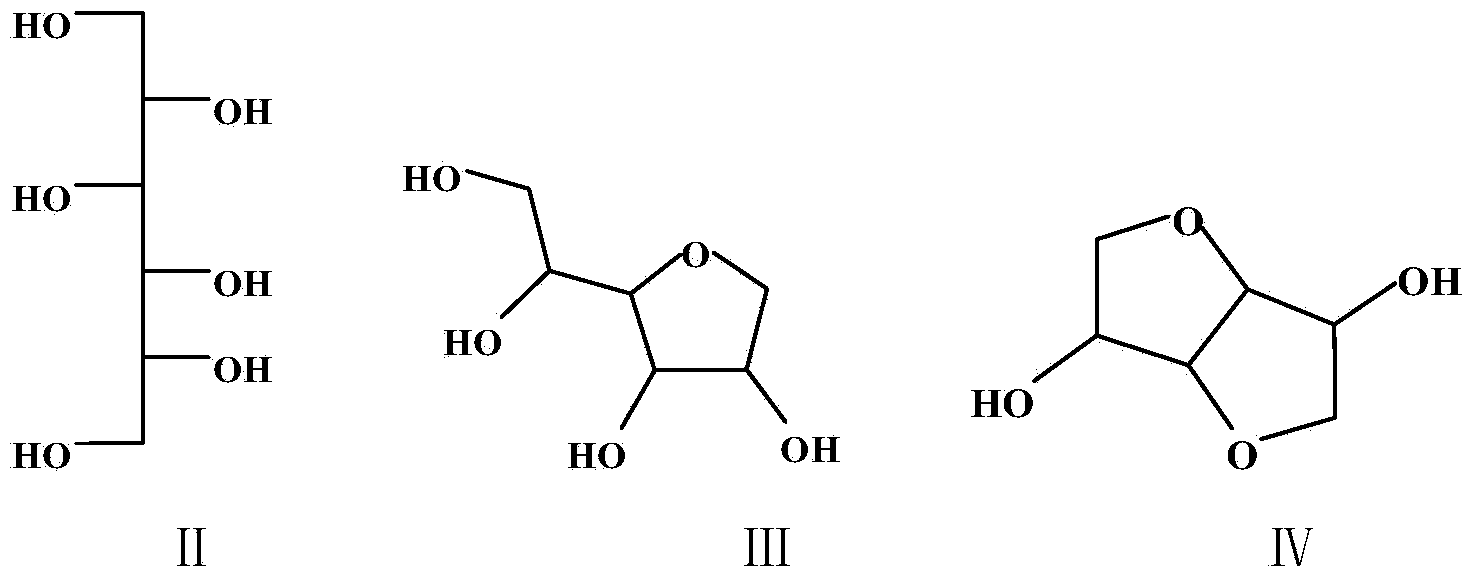

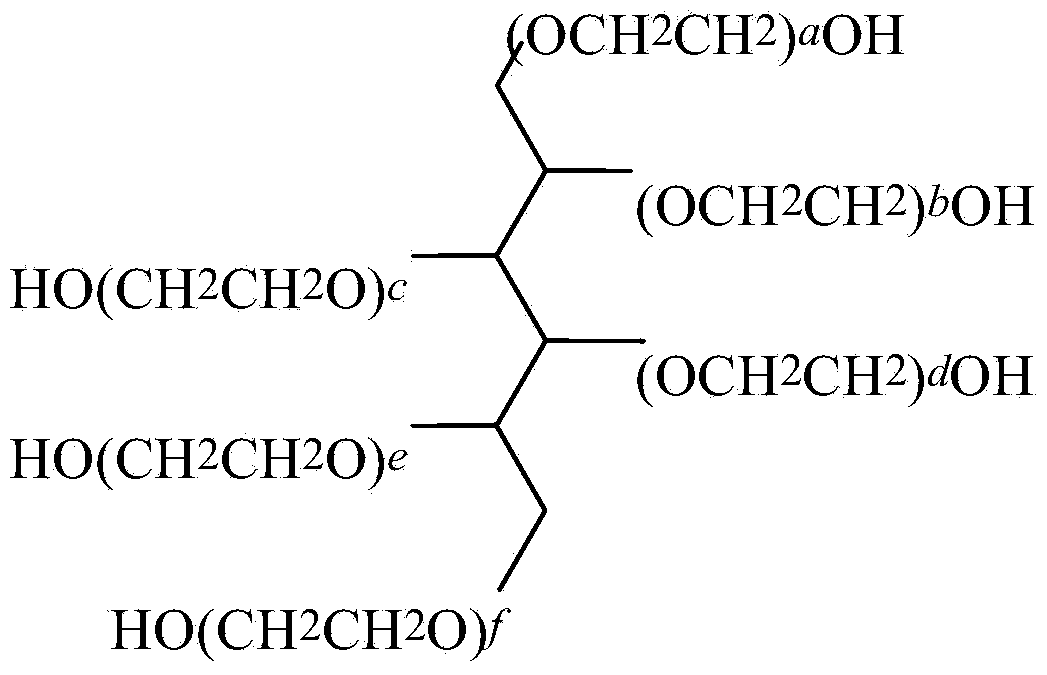

[0055] [embodiment 1~4] the preparation of polyoxyethylene sorbitol ether

[0056] In the 3L stainless steel autoclave, add the sorbitol (purity ≥ 99%) of the amount shown in Table 1, catalyst, after replacing with nitrogen, be warming up to 90 ℃, then slowly pressurize the oxirane of the amount shown in Table 1 with nitrogen Put it into an autoclave for addition polymerization reaction, control the addition rate of ethylene oxide, maintain the temperature of the kettle at 140°C to 150°C, and the pressure at 0.4MPa. After adding the ethylene oxide, aging for 2h, the pressure in the kettle is reduced to normal pressure, and the temperature is lowered. to 70-80°C, treated with synthetic magnesium silicate with 1% mass of reactant for 1 h, filtered to obtain polyoxyethylene sorbitol ether, measured and measured for hydroxyl value, the results are listed in Table 1.

[0057] The preparation result of table 1 polyoxyethylene sorbitol ether

[0058]

[0059] *The catalyst is sod...

Embodiment 5~8

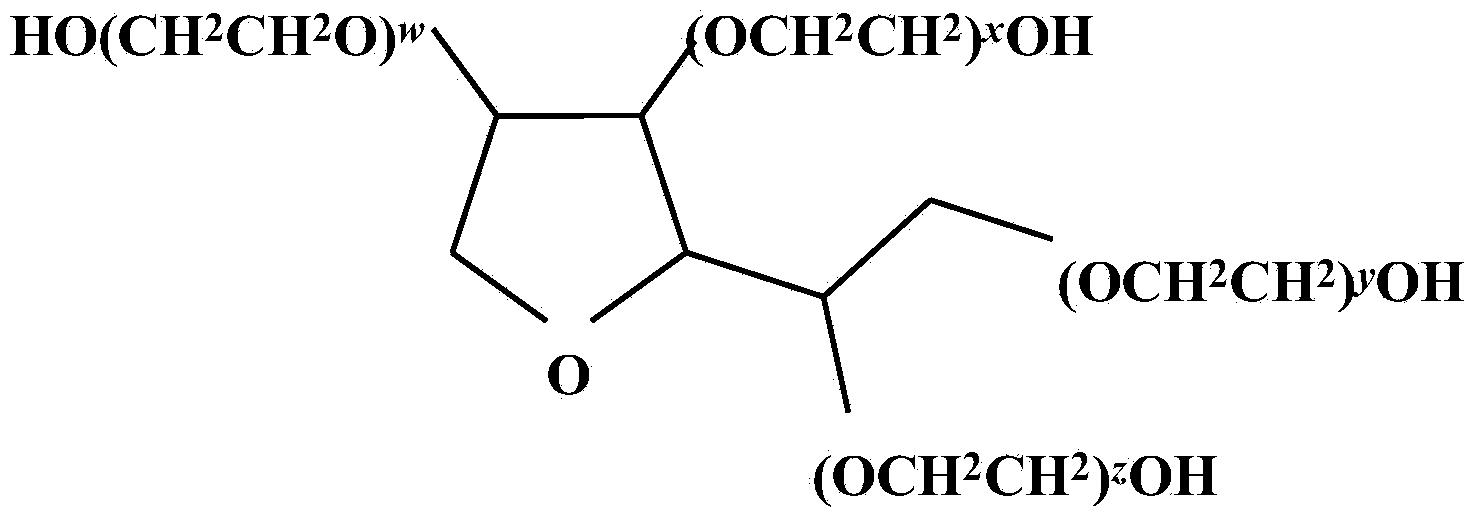

[0060] [Examples 5-8] Preparation of Polyoxyethylene-Sorbitan Ether

[0061] It is basically the same as Example 1, but the sorbitol is changed into 1,4-sorbitol (purity ≥ 99%), and the feeding amount of it and ethylene oxide and the yield and hydroxyl value of the product are shown in Table 2.

[0062] The preparation result of table 2 polyoxyethylene-sorbitan ether

[0063]

[0064] *The catalyst is sodium hydroxide.

Embodiment 9~12

[0065] [Examples 9-12] Preparation of Polyoxyethylene Isosorbide

[0066] Substantially the same as Example 1, but changing sorbitol into isosorbide (purity ≥ 99%), its charging amount and product yield and hydroxyl value of ethylene oxide are shown in Table 3.

[0067] The preparation result of table 3 polyoxyethylene isosorbide

[0068]

[0069]

[0070] *The catalyst is potassium hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com