Solid-state fermentation method of Chinese liquor

A solid-state fermentation and liquor technology, which is applied in the field of liquor production, can solve the problems of low summer yield, large floor area, and difficult temperature control, and achieve the effects of improving utilization rate, improving liquor quality, and improving land utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] a. Moisten 42000kg of sorghum grains, cook and cool to 15°C, add Daqu and mix the grain unstrained spirits into the fermentation container and seal it, then transport it to a separate fermentation room, arrange 3 rows and stack 3 layers;

[0031] b. Cool the fermented grains that have been steamed once to 20°C, add the fermented grains mixed with Daqu and rice husks, put them in a fermentation container, seal them, and transport them to a separate fermentation room, arrange 3 rows and stack 3 layers;

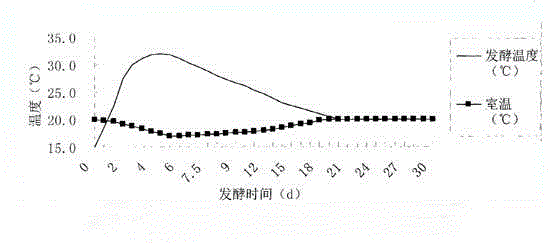

[0032] c. For the grain unstrained spirits in step a, according to fermentation 0-5d, the temperature of fermented grain unstrained spirits rises from 15°C to 32°C with a smooth curve, and the temperature of fermented grain unstrained spirits drops to 20°C with a smooth curve for 6-15 days of fermentation, and ferments for 16-15 days. For 30 days, the temperature of the fermented grain unstrained spirits was kept at 20°C and the fermentation temperature was controlled to c...

Embodiment 2

[0040] a. Moisten 42000kg of sorghum grains, cook and cool to 18°C, add Daqu and mix the grain unstrained spirits into the fermentation container and seal it, then transport it to a separate fermentation room, arrange 3 rows and stack 3 layers;

[0041] b. Cool the fermented grains that have been steamed once to 22°C, add the fermented grains mixed with Daqu and rice husks, put them in a fermentation container and seal them, then transport them to a separate fermentation room, arrange 3 rows and stack 3 layers;

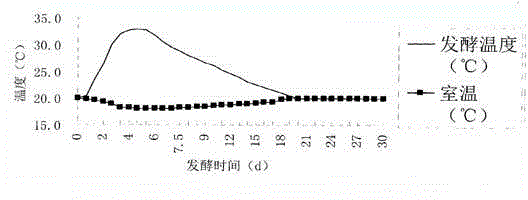

[0042] c. For the fermented grain unstrained spirits in step a, according to fermentation 0-5d, the temperature of the fermented grain unstrained spirits rises from 18°C to 33°C with a smooth curve, and after 6-15 days of fermentation, the temperature of the fermented grain unstrained spirits drops to 22°C with a smooth curve, and fermented for 16 days. For ~30 days, the temperature of the fermented grain unstrained spirits was kept at 22°C and the fermentation tempe...

Embodiment 3

[0050] a. Moisten 42000kg of sorghum grains, cook and cool to 22°C, add Daqu and mix the grain unstrained spirits into the fermentation container and seal it, then transport it to a separate fermentation room, arrange 3 rows and stack 3 layers;

[0051] b. Cool the fermented grains that have been steamed once to 24°C, add the fermented grains mixed with Daqu and rice husks, put them in a fermentation container and seal them, then transport them to a separate fermentation room, arrange 3 rows and stack 3 layers;

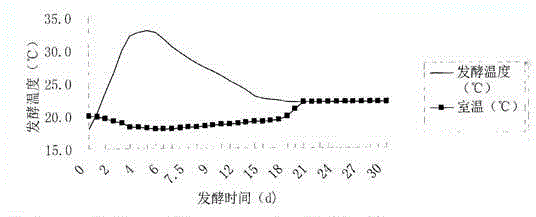

[0052] c. For the fermented grain unstrained spirits in step a, according to fermentation 0-5d, the temperature of the fermented grain unstrained spirits rises from 22°C to 35°C with a smooth curve, and after fermentation for 6-15 days, the temperature of the fermented grain unstrained spirits drops to 25°C with a smooth curve, and fermented for 16 days. For ~30 days, the temperature of the fermented grain grains was kept at 25°C and the fermentation temperature was co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com