Application of bacillus circulans in production of Maotai-flavor Chinese spirit

A technology of Bacillus Circularis and Maotai-flavor liquor, which is applied in the field of bioengineering, can solve the problems of less applied research, low high-quality product rate, unstable liquor style and quality, etc., and achieves the improvement of liquor quality and good economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

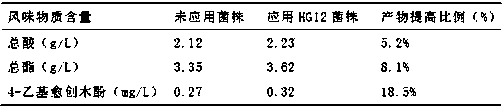

Embodiment 1

[0038] Bacillus circulans ( Bacillus circulans ) The application of the HG12 strain in the production of Maotai-flavor liquor, the steps are as follows:

[0039] (1) Use an inoculation loop to pick a ring of Bacillus circulans HG12 strain from the slant of the strain test tube and inoculate it into 10 mL of liquid seed medium, and cultivate it for 12 hours at 40°C and 160 r / min to obtain an activated liquid seed.

[0040] (2) Inoculate the liquid seeds prepared in step (1) into 200mL liquid medium at an inoculum amount of 5% (v / v), and culture them at 50°C and 200r / min for 16 hours to obtain the strain liquid culture things.

[0041] (3) Inoculate the liquid culture of the strain obtained in step (2) with an inoculum amount of 10% (v / w) into the solid fermented grains of Maotai-flavored liquor after steaming, and operate according to the production process of Maotai-flavored liquor. Fermented in the pond for 30 days to obtain fermented wine grains, which were distilled to o...

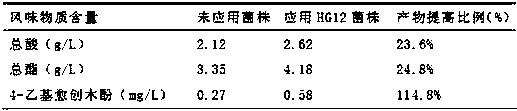

Embodiment 2

[0048] Bacillus circulans ( Bacillus circulans ) The application of the HG12 strain in the production of Maotai-flavor liquor, the steps are as follows:

[0049] (1) Use an inoculation loop to pick 1 ring of Bacillus circulans HG12 strain from the slant of the strain test tube and inoculate it into 10 mL of liquid seed medium, and culture it for 16 hours at 35°C and 120 r / min to obtain an activated liquid seed.

[0050] (2) Inoculate the liquid seeds prepared in step (1) into 200mL liquid fermentation medium at an inoculum amount of 2% (v / v), and culture them for 24 hours at 40°C and 150r / min to obtain strain liquid Cultures.

[0051] (3) Inoculate the liquid culture of the strain obtained in step (2) with an inoculum amount of 1% (v / w) into the solid fermented grains of Maotai-flavored liquor after steaming, and operate according to the production process of Maotai-flavored liquor. Fermented in the pond for 32 days to obtain fermented wine grains, which were distilled to o...

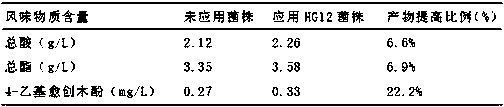

Embodiment 3

[0058] Bacillus circulans ( Bacillus circulans ) The application of the HG12 strain in the production of Maotai-flavor liquor, the steps are as follows:

[0059] (1) Same as step (1) in Example 1.

[0060] (2) Inoculate the liquid seeds prepared in step (1) into 200 g of solid medium at an inoculation amount of 3% (v / w), and culture at 50°C for 3 days to obtain a solid culture of the strain.

[0061] (3) Inoculate the solid culture of the strain obtained in step (2) at an inoculum amount of 10% (w / w) into the solid fermented grains of Maotai-flavored liquor after steaming, and operate according to the production process of Maotai-flavored liquor. Fermented in the pond for 30 days to obtain fermented wine grains, which were distilled to obtain Maotai-flavored liquor with an ethanol concentration of 60% (v / v).

[0062] The solid medium in the step (2): 100g each of wheat and sorghum, pulverize the two to a particle size of 2.0mm, add 160mL of water, infiltrate for 20h, cook at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com