Reinforced concrete hollow cone mountain wind power flexible foundation and its construction method

A reinforced concrete and flexible foundation technology, which is applied in basic structure engineering, construction and other directions, can solve the problems of high construction technology requirements, large amount of steel reinforcement, excavation of large foundation muck and other problems, so as to increase engineering risks, increase engineering costs, The effect of reducing the base cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

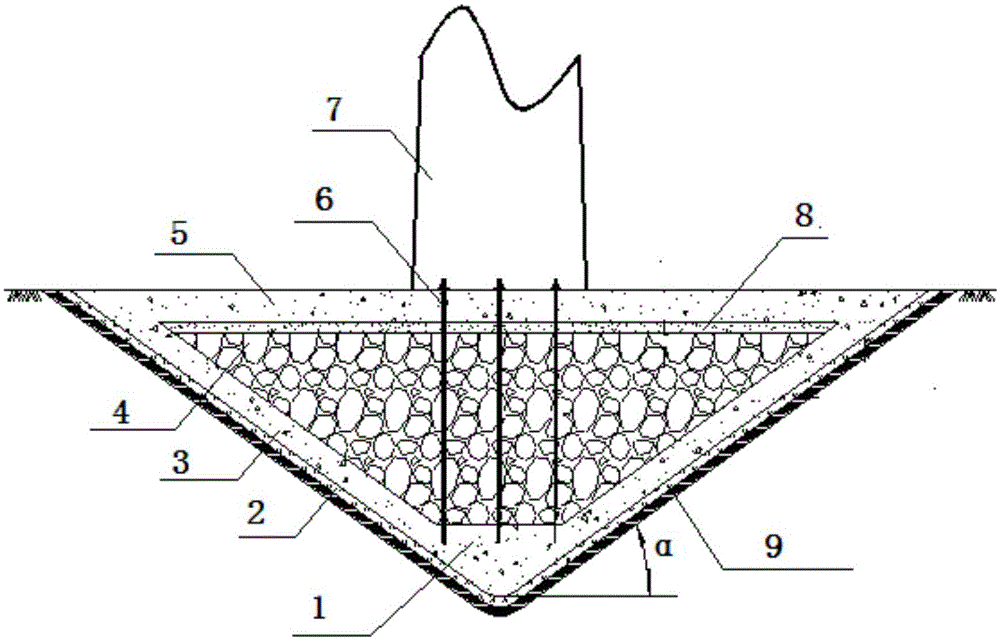

[0036] Further describe the technical scheme of the present invention below in conjunction with construction method and accompanying drawing.

[0037] A 2MW wind power foundation needs to be built in a mountainous area. The diameter of the foundation tower is 4m. The maximum vertical load borne by the foundation is 2800kN, the maximum horizontal force is 380kN, and the maximum bending moment is 30.6MN·m.

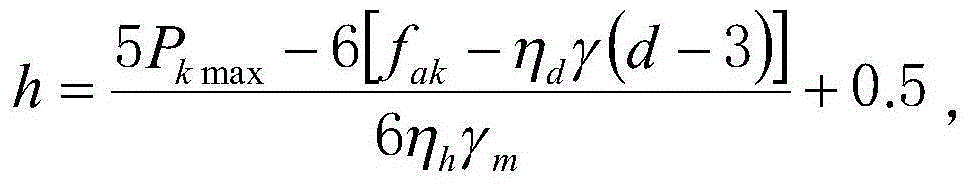

[0038] Step 1: First determine the diameter of the foundation roof, take the diameter of the foundation roof as 9m, and substitute it into the formula to obtain the depth of the foundation pit as 2.5m.

[0039] Step 2: Excavate the foundation pit, excavate the bottom into a conical shape, pile up the muck 4 around the foundation pit for use, and the angle α between the wall of the conical foundation pit and the ground is 30 degrees.

[0040] Step 3: Lay a 15cm thick waste tire rubber particle layer 9 along the wall of the foundation pit.

[0041] Step 4: Lay a 10cm-thick fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com