Sealing device and method for microcosmic displacement model injection and production opening

A sealing device and model technology, used in sealing/isolation, earth-moving drilling, wellbore/well components, etc., can solve the problem of shortening the service life of O-rings, leakage, easy changing positions of O-rings and glass surfaces, etc. problem, to achieve the effect of strong wear resistance and reliable sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

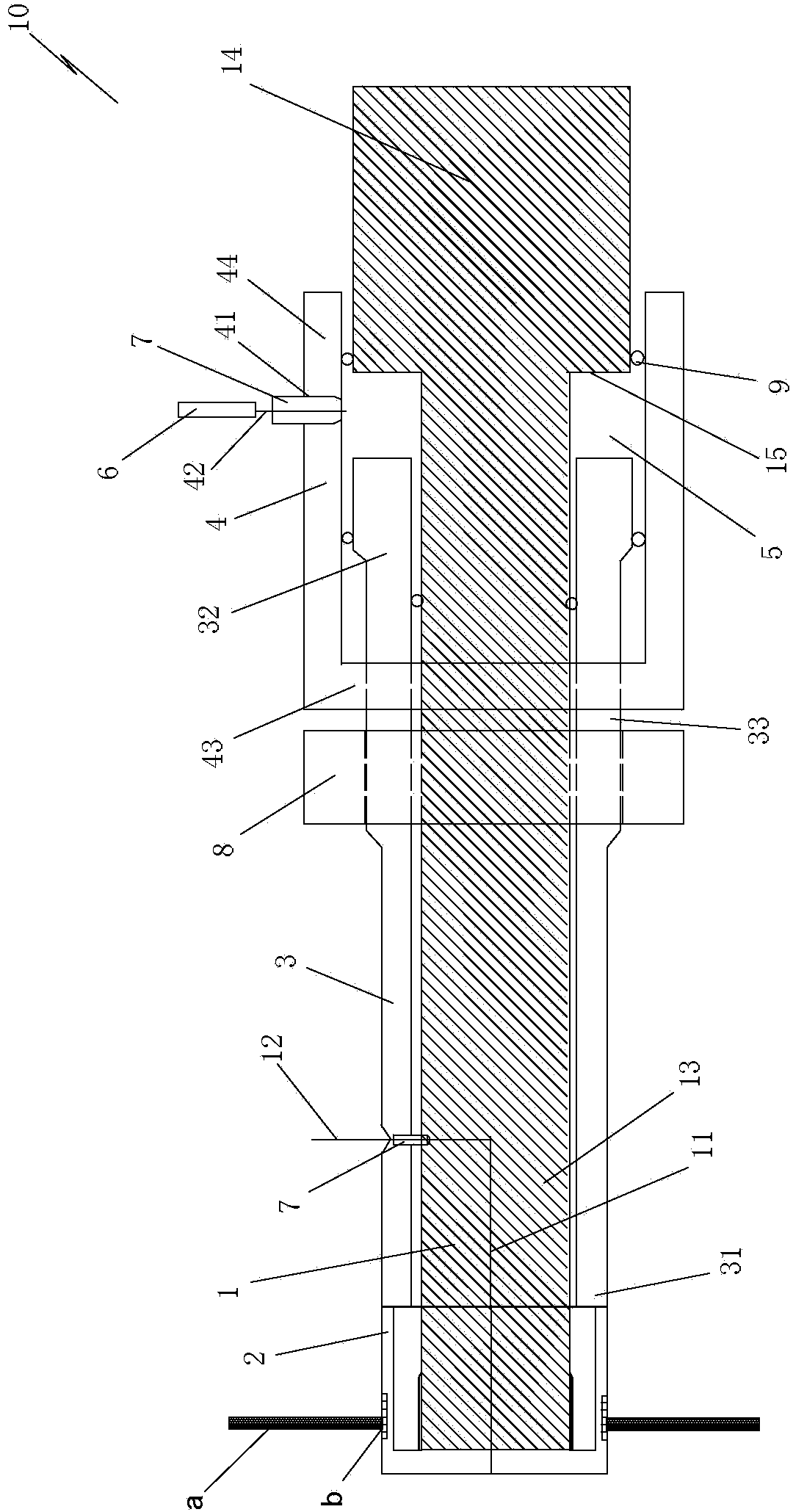

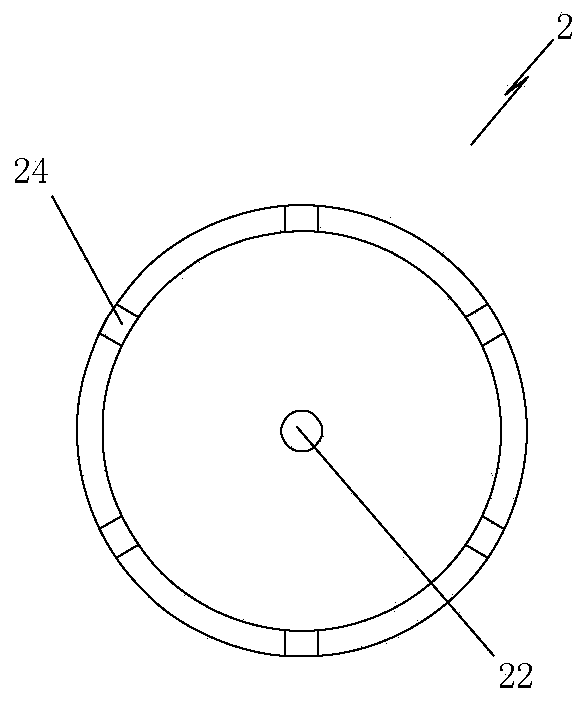

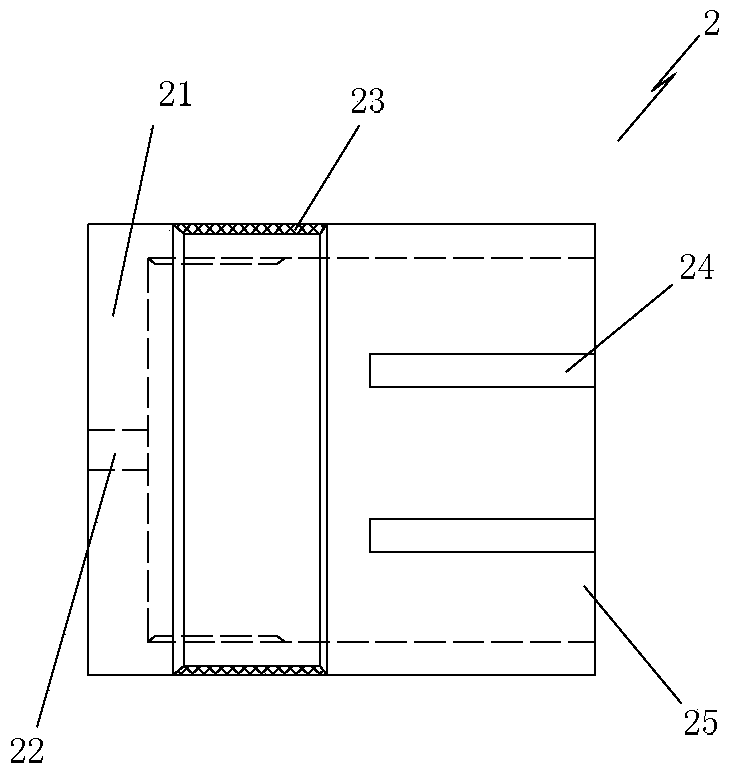

[0028] Such as figure 1 As shown, the present invention provides a sealing device 10 for injection and production ports of a microscopic displacement model. The microscopic glass etching model is commonly used in the microscopic displacement model, and the microscopic glass etching model a is adopted in this embodiment. The invention can also be applied to the injection-production opening sealing of one-dimensional / two-dimensional / three-dimensional cementation-displacement models. The sealing device 10 includes a main shaft 1. The main shaft 1 is composed of two sections of cylinders with different diameters. The main shaft 1 is provided with a liquid passage 11 inside, and the liquid passage 11 is connected with a fluid injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com