A sensor installation angle selection method for three-point roundness error separation technology

A technology of roundness error and installation angle, which is applied in the field of high-precision measurement of precision rotary bodies, can solve problems that affect the separation accuracy of roundness error and wrong error separation results, and achieve the goal of avoiding loss of precision, short angle selection cycle, and simple implementation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

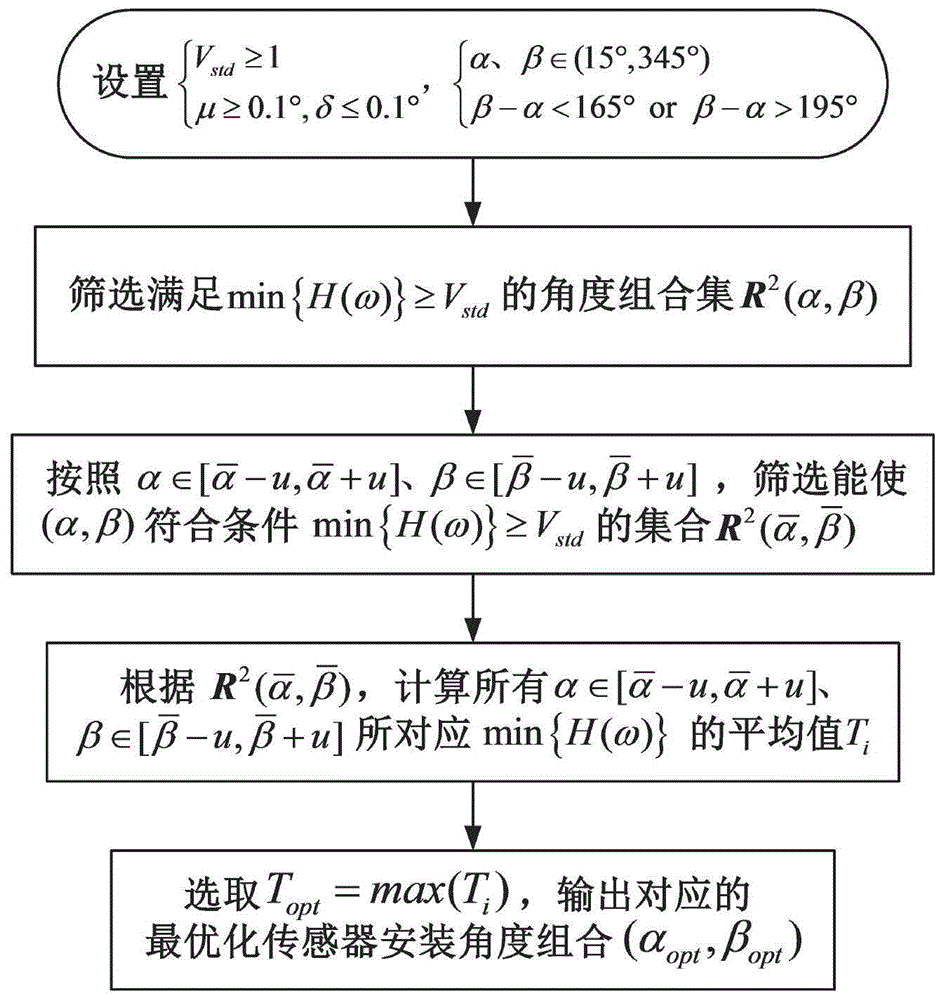

[0030] The process of the present invention is as figure 1 As shown, below in conjunction with accompanying drawing the embodiment of the present invention is described in detail:

[0031] 1. Representation formula of weight function in three-point roundness error separation technology

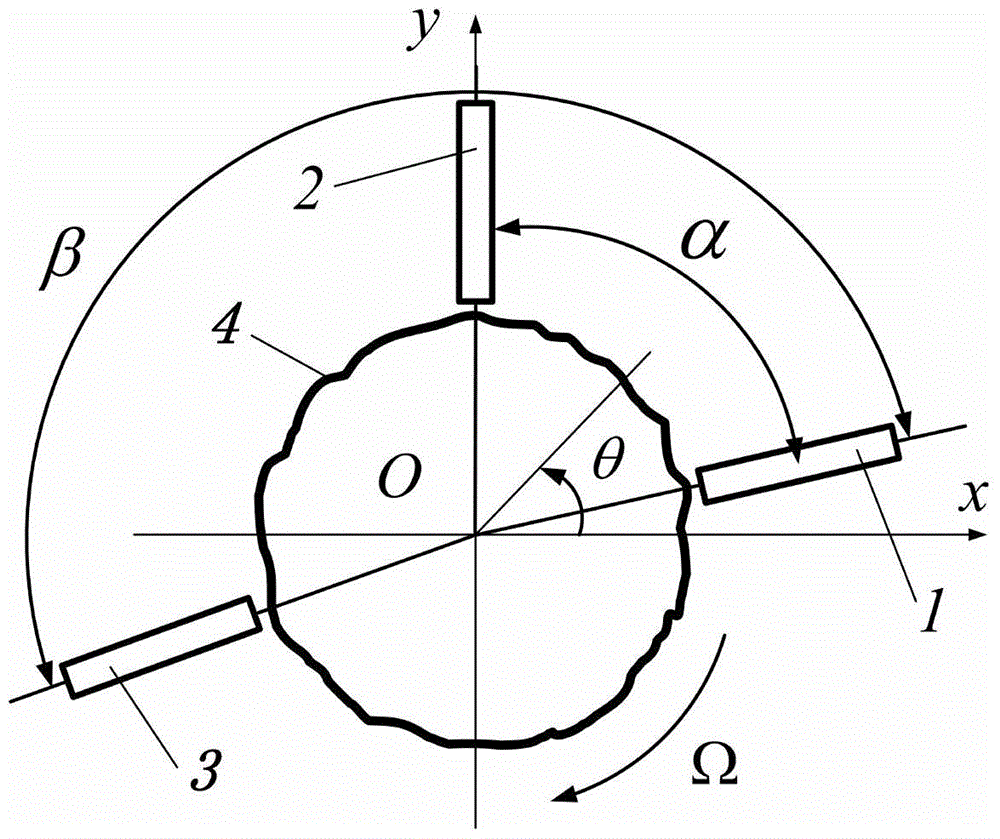

[0032] Such as figure 2 As shown, three sensors are installed in the radial direction of the measured circular section 4, then according to the three-point roundness error separation technology, the weight function expression can be derived as:

[0033] H(ω)=c 0 e jω0 +c 1 e jωα +c 2 e jωβ

[0034] The modulus expression of the available weight function is:

[0035] | H ( ω ) | = [ 1 + - s i n β ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com