Suspension rope and stable rope tension online detection device and method in vertical shaft construction

A technology of tension detection and suspension rope, which is applied in the direction of tension measurement, instruments, signal transmission systems, etc., can solve the problems of large lateral pressing force, wire rope damage, inaccurate measurement, etc., to avoid measurement errors, easy installation, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

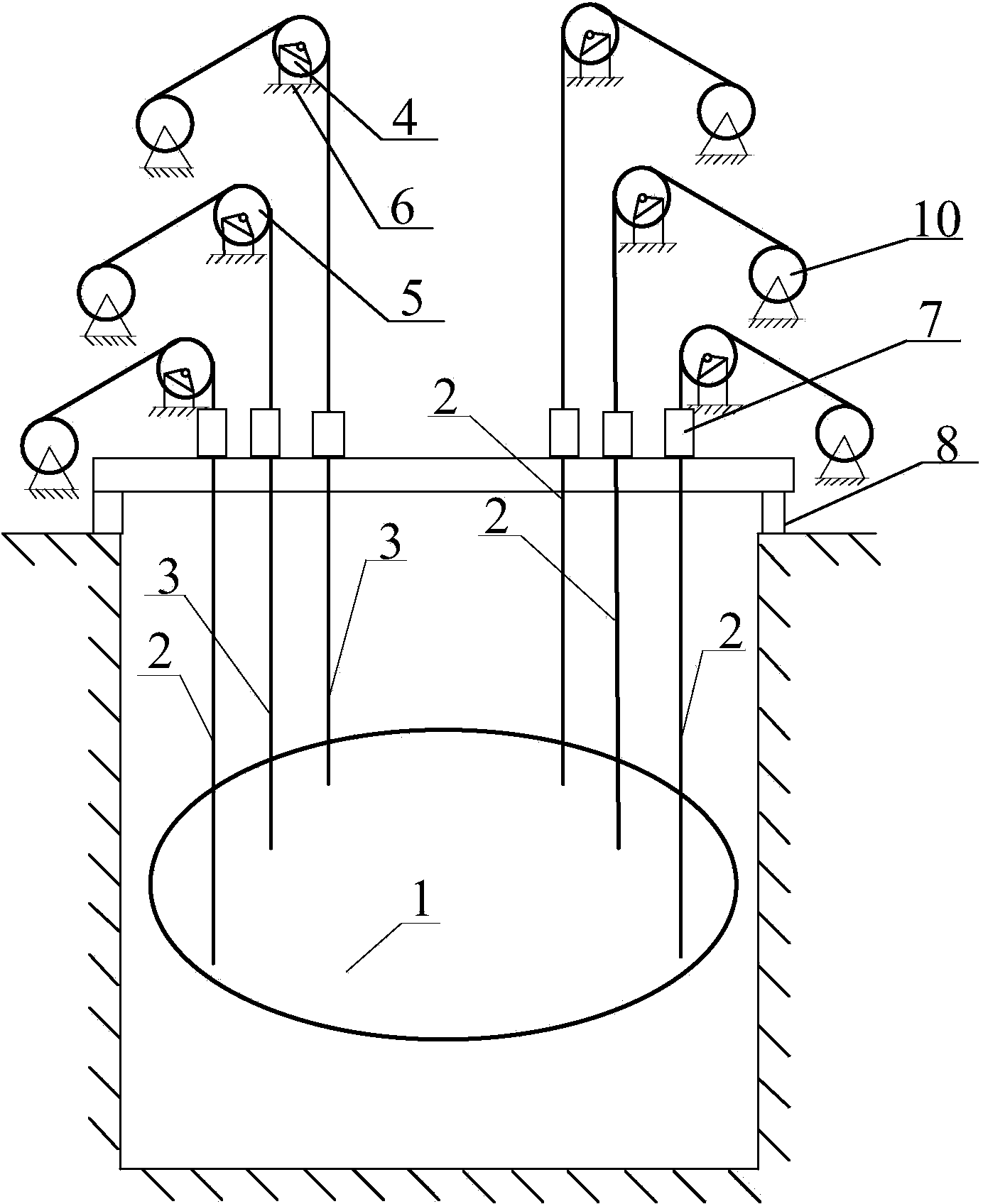

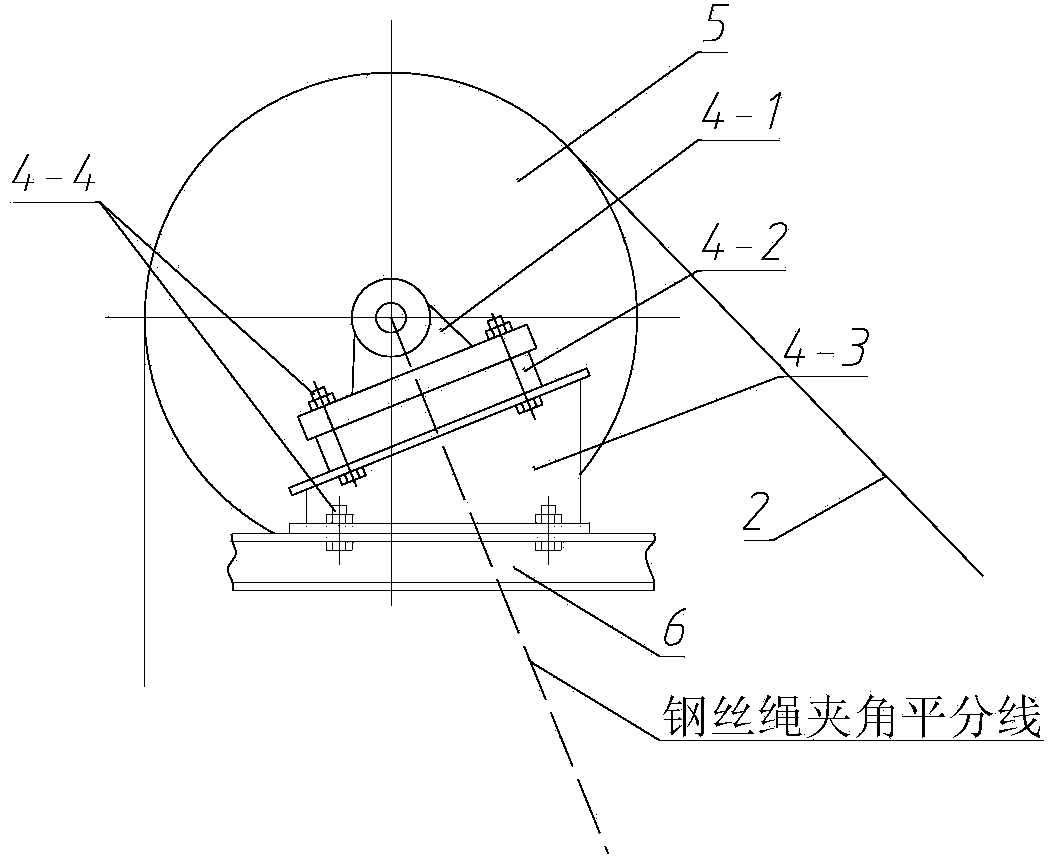

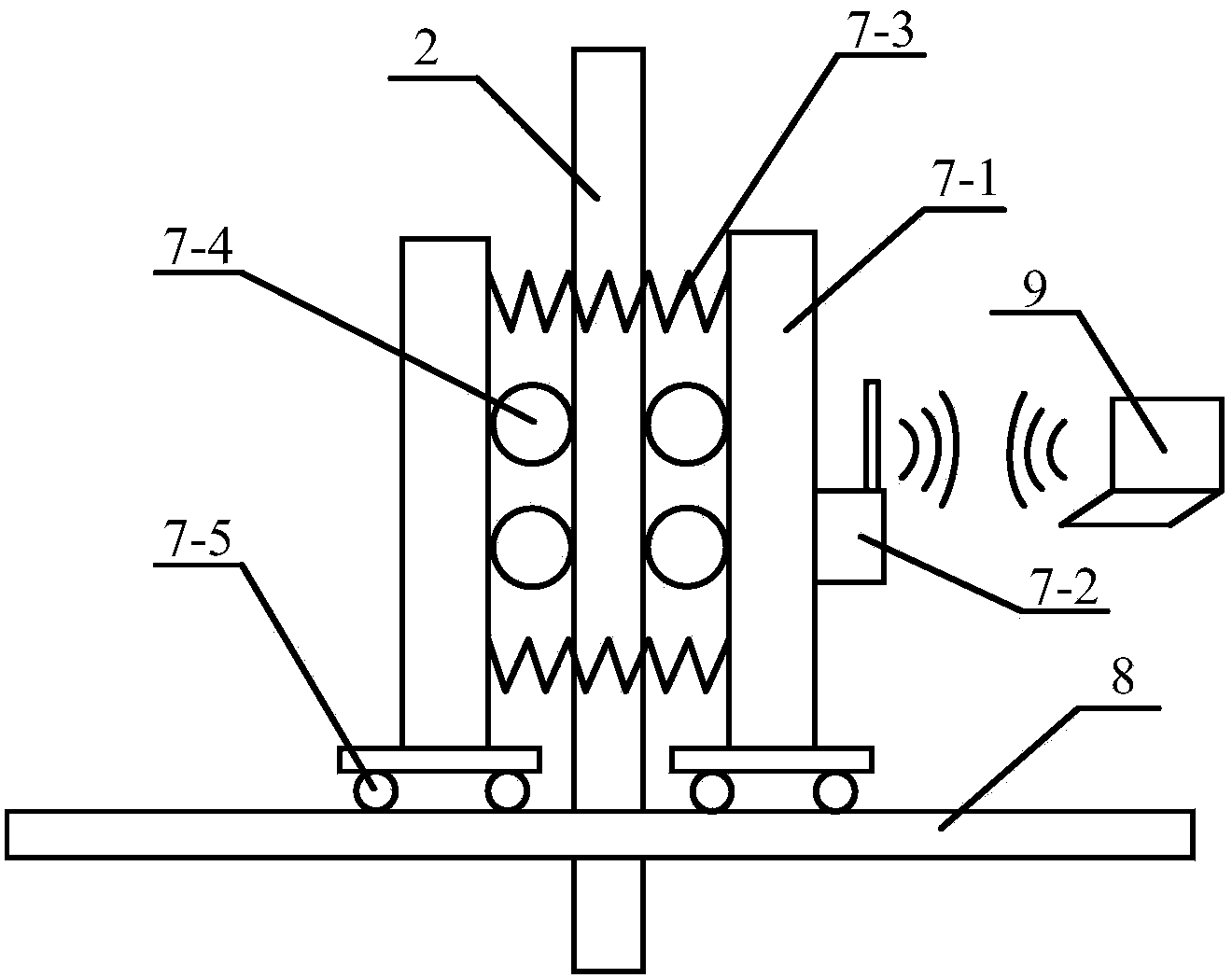

[0022] The online detection device of the suspension rope and the tension of the stable rope of the construction shaft of the present invention comprises a signal processor 9, a well cover platform 8, a derrick 6 arranged above the well cover platform 8, and a plurality of sky wheels 5 arranged on the derrick 6 at intervals, One end is fixed by the winch 10, the other end obliquely bypasses the sky wheel 5 and then vertically extends into the well to connect multiple suspension ropes 2 or stable ropes 3 on the hanging pan 1 in the well, and the derrick at the position of each sky wheel 5 6 are fixed with a tension detection device 4, the tension detection device 4 includes a bearing support 4-1, a pressure sensor 4-2 and an inclined plane support 4-3, and the inclined plane support 4-3 is fixed on the derrick by fixing bolts 4-4 6, the pressure sensor 4-2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com