Method for gaining service life of helicopter drive system component

A technology of a transmission system and an acquisition method, which is applied in the field of acquiring the life of helicopter transmission system components, can solve the problems of complex surface shape of components, inability to obtain accurate life values of components, and inability to grasp the stress and damage of components in flight in time, and reduce Potential safety hazards, improved safety, and the effect of improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered.

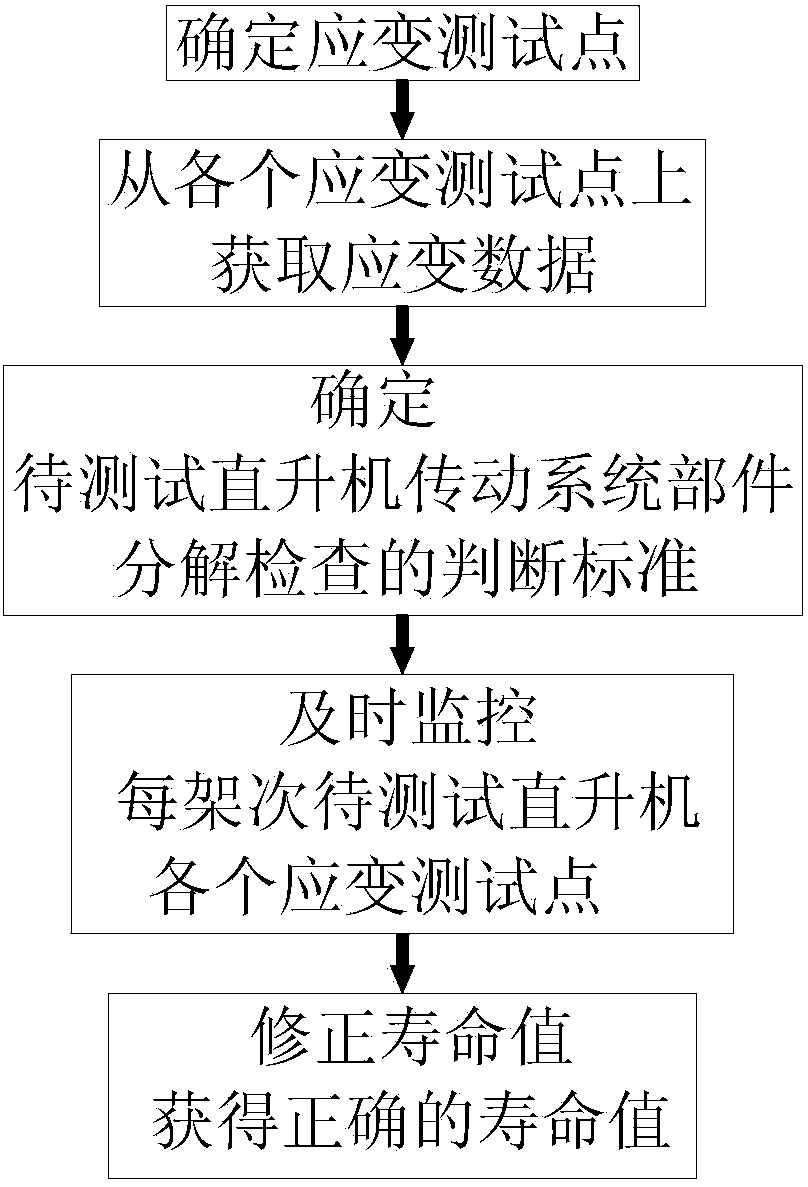

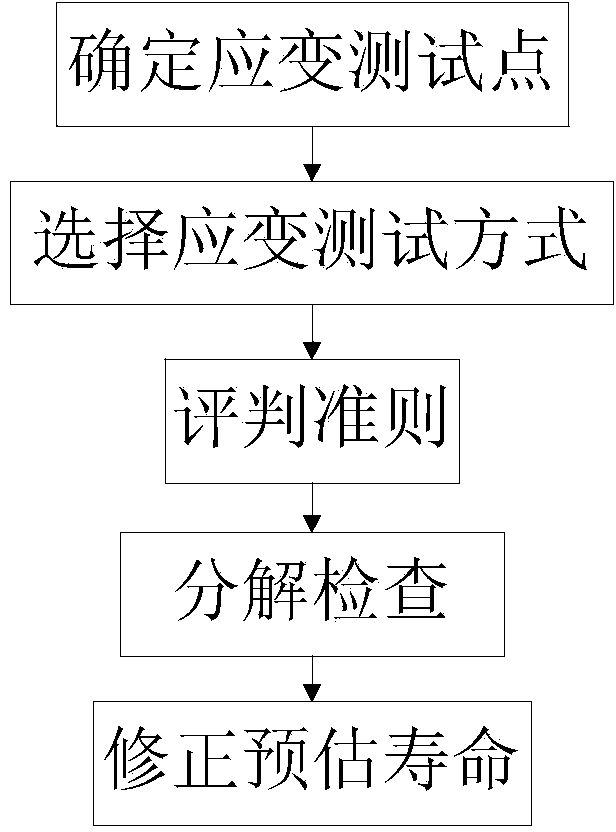

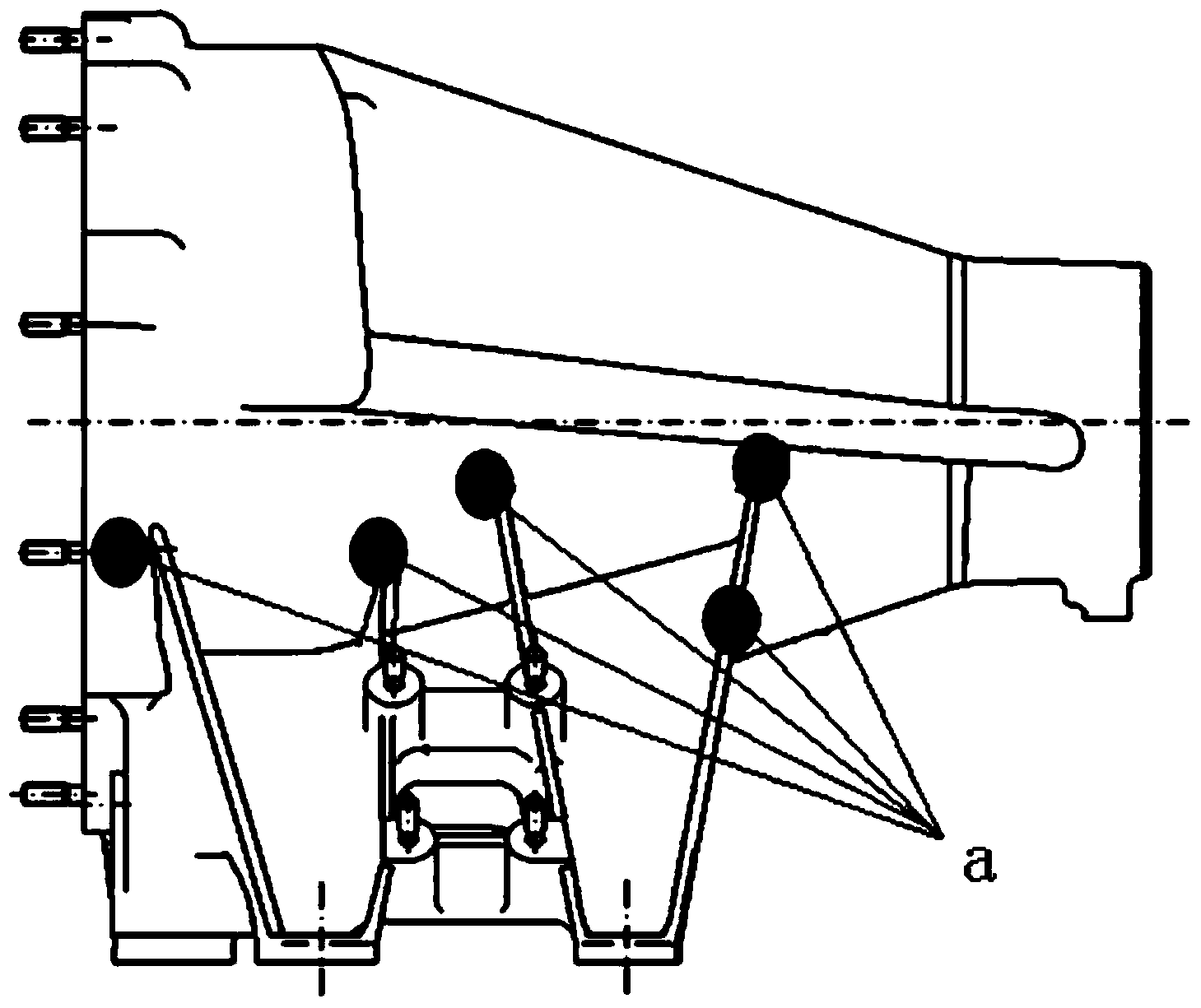

[0042] figure 1 It is a structural block diagram of a method for obtaining the life of a helicopter transmission system component in a preferred embodiment of the present invention; figure 2 It is a schematic flow chart of the method for obtaining the service life of helicopter transmission system components in a preferred embodiment of the present invention; image 3 It is a schematic diagram of the position of some strain test points of the tail reducer casing in the preferred embodiment of the present invention.

[0043] Such as figure 1 As shown, the acquisition method of a kind of helicopter transmission system component life of the present embodiment comprises the following steps: a, according to the ground joint test and the flight test of the helicopter to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com