Bare conductor changing auxiliary device of enameling machine

A kind of auxiliary device and bare wire technology, applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of disconnection and shutdown, time-consuming and laborious, etc., to improve the efficiency of material change, reduce labor intensity, and increase the safety and reliability of equipment performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following further describes the present invention with reference to the accompanying drawings and specific embodiments to facilitate a clearer understanding of the technical ideas claimed by the present invention.

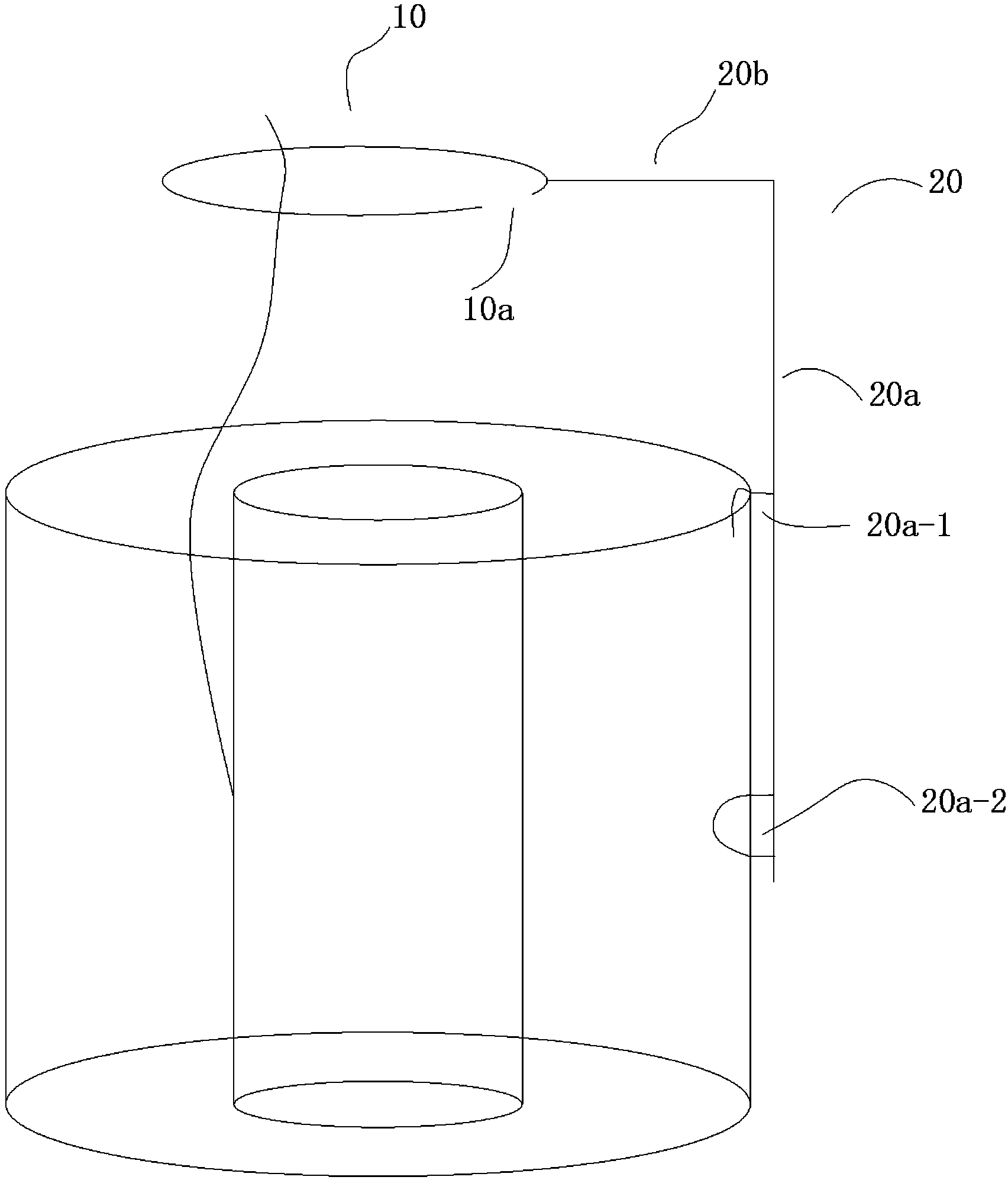

[0011] Such as figure 1 The bare wire refueling auxiliary device of the enamelled machine of the present invention shown includes a wire management ring 10 through which the bare wires can pass and a support rod 20 for supporting and fixing the wire management ring 10, the wire management ring 10 is a central axis and A ring-shaped wire with a vertical horizontal plane; the support rod 20 includes a rod main body 20a vertically arranged and a connecting rod 20b extending horizontally from the top of the rod main body 20a. The rod body 20a is provided with a rod body for fixing the support rod 20 on the The first support portion 20a-1 on the wire basket and the second support portion 20 a-2 located below the first support portion 20 a-1; the end of the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com