Conductive slip ring assembly assembling method

A conductive slip ring and assembly method technology, which is applied in the direction of electrical components, slip ring manufacturing, circuits, etc., can solve the problems that product reliability and pass rate cannot be effectively guaranteed, and the assembly accuracy of miniaturized products cannot be effectively controlled, so as to achieve compact structure , Strict glue filling method, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention comprises the following steps:

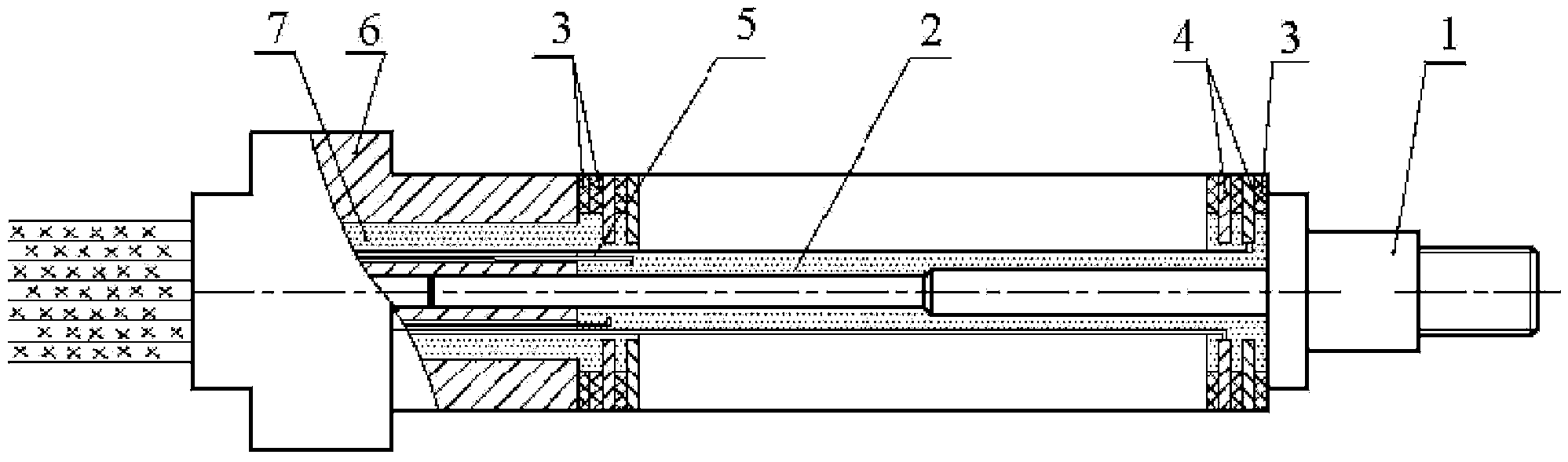

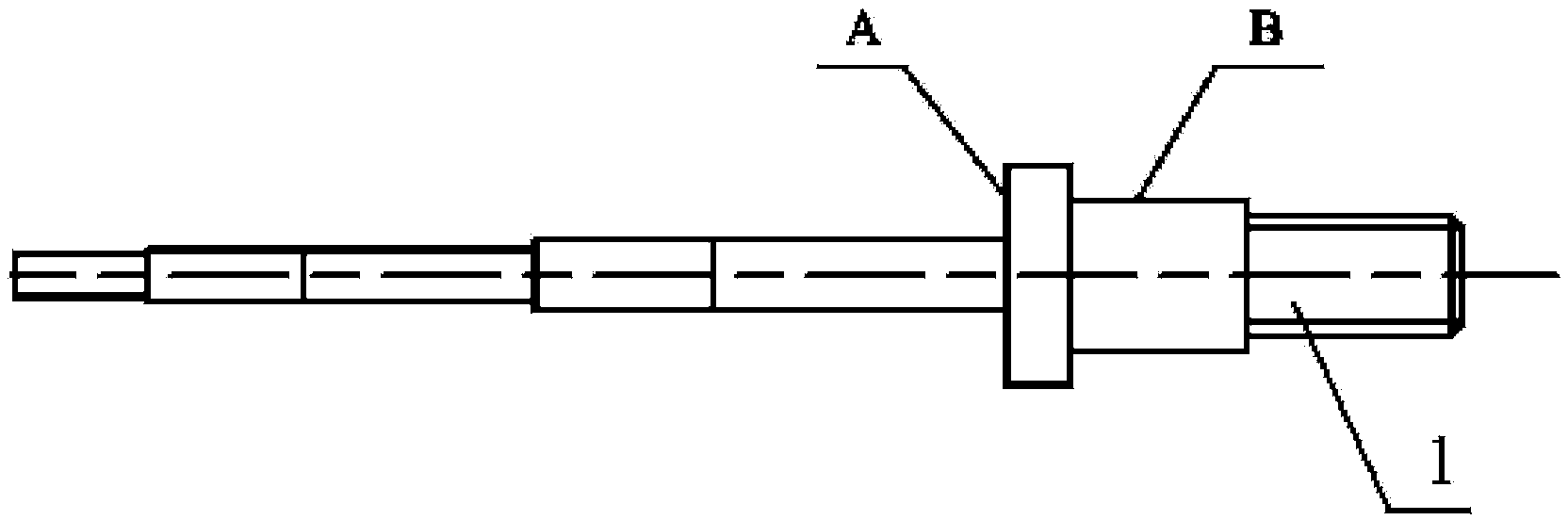

[0030] 1. After the small journal 1 is assembled and cleaned, the special two-component insulating epoxy adhesive 2 is poured to form the small journal component glue filling. After machining, the small journal assembly is formed.

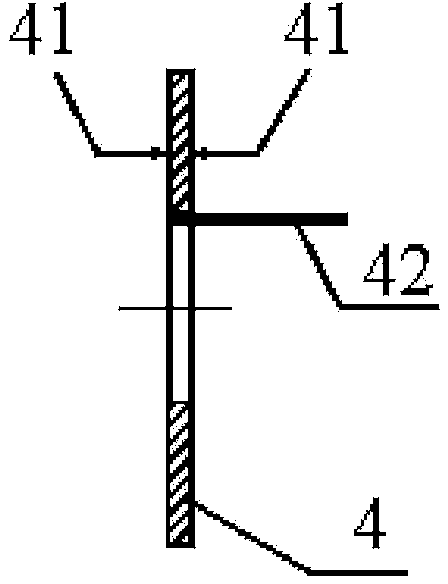

[0031] 2. Weld the conductive slip ring piece 4 to lead out the wire 5 to form a slip ring assembly.

[0032] 3. First install a piece of insulating gasket 3 on the small journal assembly, and then stack the slip ring assembly and insulating gasket 3 sequentially in a way that a slip ring assembly and a piece of insulating gasket 3 form a group, and assemble 28 groups in total. Finally, after a piece of insulating spacer 3 is installed, the large journal 6 is pressed into it to form a conductive slip ring assembly blank.

[0033] 4. Vacuum infuse the conductive slip ring assembly blank with the special small conductive rod epoxy potting glue 7 (model KMT-206) to form a conductive slip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com