Power cable paying-off support

A power cable and electric technology, applied in the direction of cable laying equipment, etc., can solve the problems of time-consuming, uneconomical, high center of gravity, etc., and achieve the effects of saving laying personnel, convenient loading and unloading, and low center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

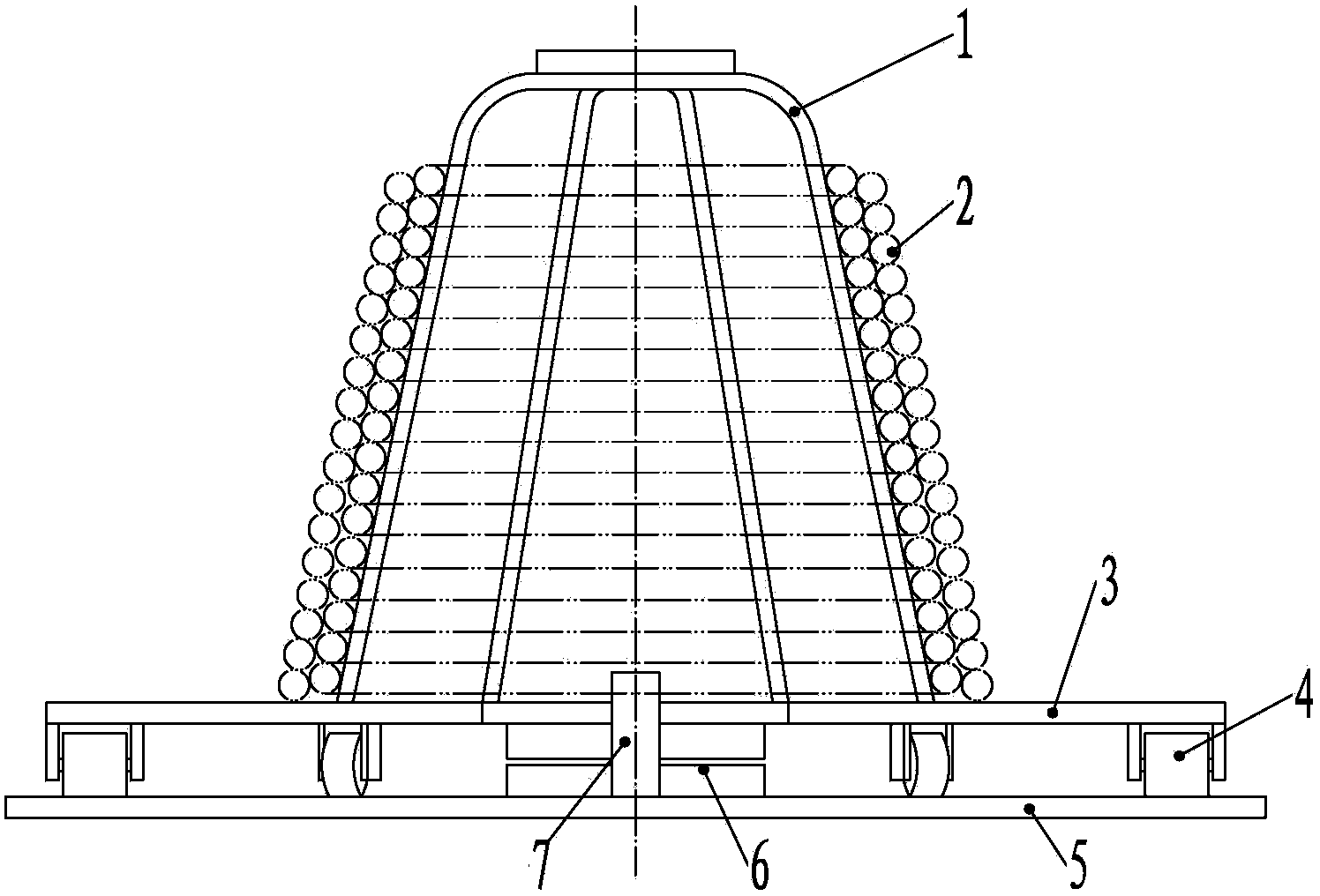

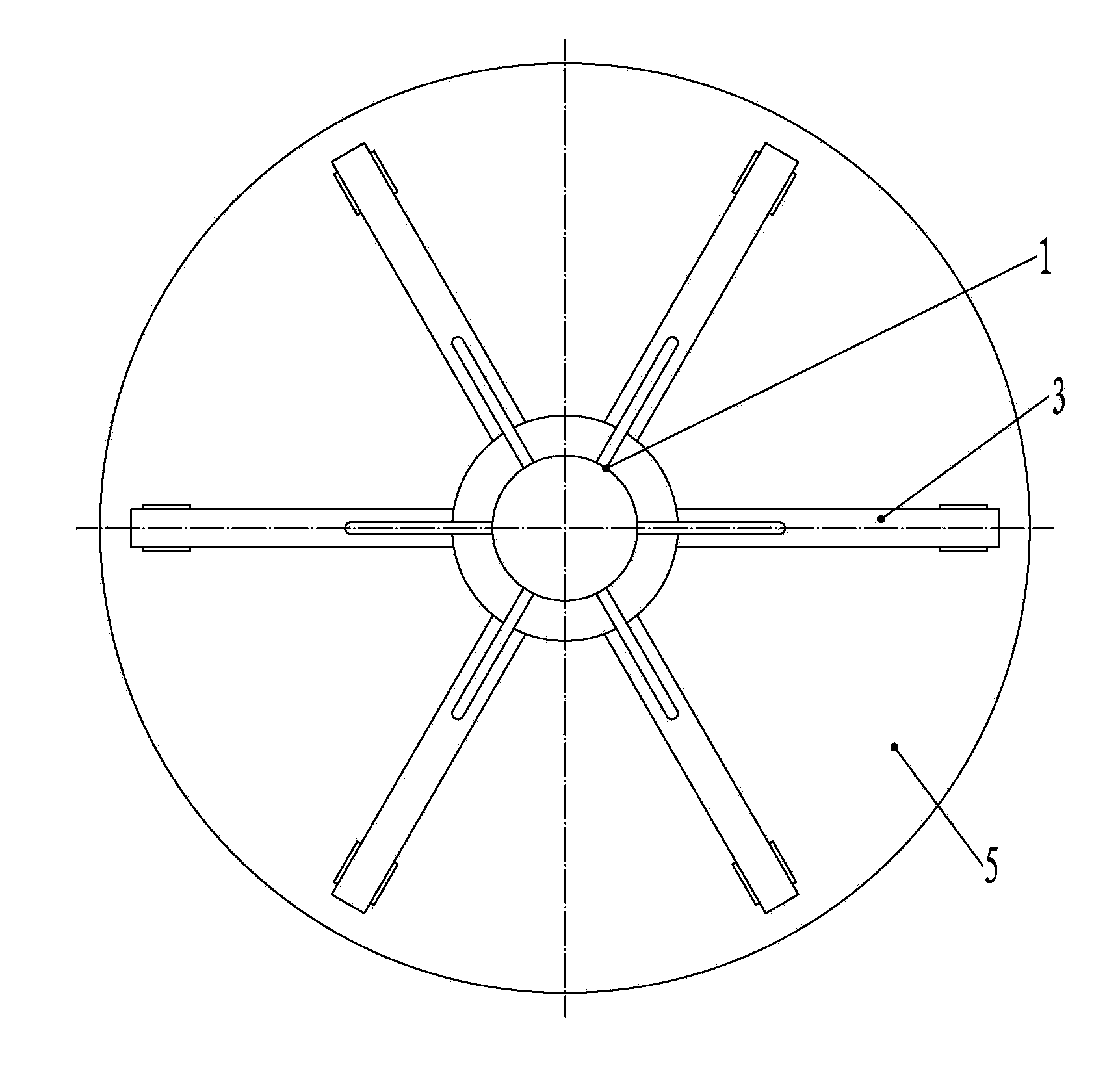

[0012] The power cable pay-off bracket of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0013] figure 1 It is a structural schematic diagram of the power cable pay-off bracket of the present invention, figure 2 yes figure 1 top view. In the figure, this power cable pay-off support includes a chassis 5, a rotating shaft 7 is arranged at the center of the chassis 5, a turntable frame 3 is arranged above the chassis 5, and a supporting roller 4 is arranged on the bottom surface of the outer ring of the turntable frame 3, and the turntable An electric brake 6 is arranged between the frame 3 and the chassis 5, the electric brake 6 is installed at the rotating shaft 7, the lower plate of the electric brake 6 is fixed on the chassis 5, the upper plate of the electric brake 6 is fixed on the turntable frame 3, and the turntable frame 3 The upper end face is provided with a squirrel cage frame 1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com