Stator of motor and manufacturing method thereof

A manufacturing method and stator technology, which are applied in the manufacture of motor generators, stator/rotor bodies, electrical components, etc., can solve problems such as adverse effects on the service life of motors, increase wear of brush devices, etc., and achieve electromagnetic interference reduction and simplification. structure, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

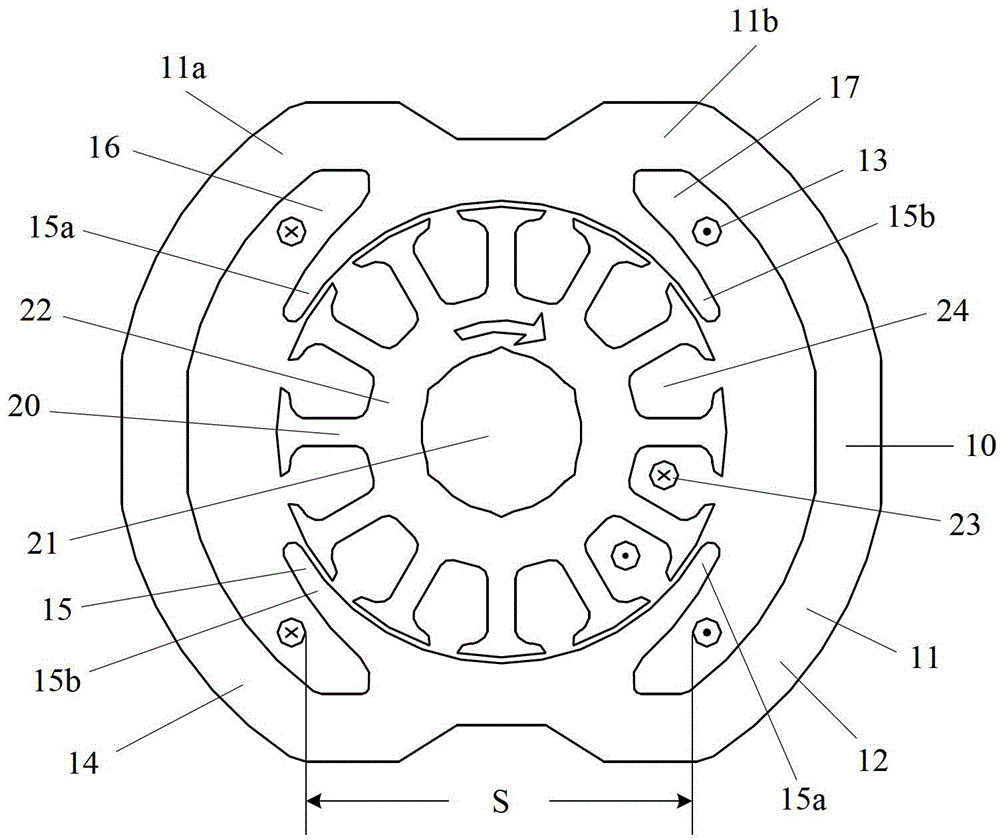

[0052] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

[0053] Figure 5 The cross-sectional structure of the stator and rotor of the motor according to the first embodiment of the present invention is shown. Wherein, the motor is an AC / DC dual-purpose motor. The stator 30 of the motor includes two pairs of main magnetic poles 31 and field windings 33, and the rotation direction of the rotor 32 is clockwise (as shown by the arrow in the figure). The main magnetic pole 31 includes a pole body 34, a pole shoe 35a at the armature turning-in side and a pole shoe 35b at the armature turning-out side, and the concentrated winding is embedded in the stator between the pole shoe 35a at the armature turning-in side and the pole body 34 The slot 36 and the stator slot 37 between the pole shoe 35 b and the pole body 34 on the armature turning-out side are the field winding 33 .

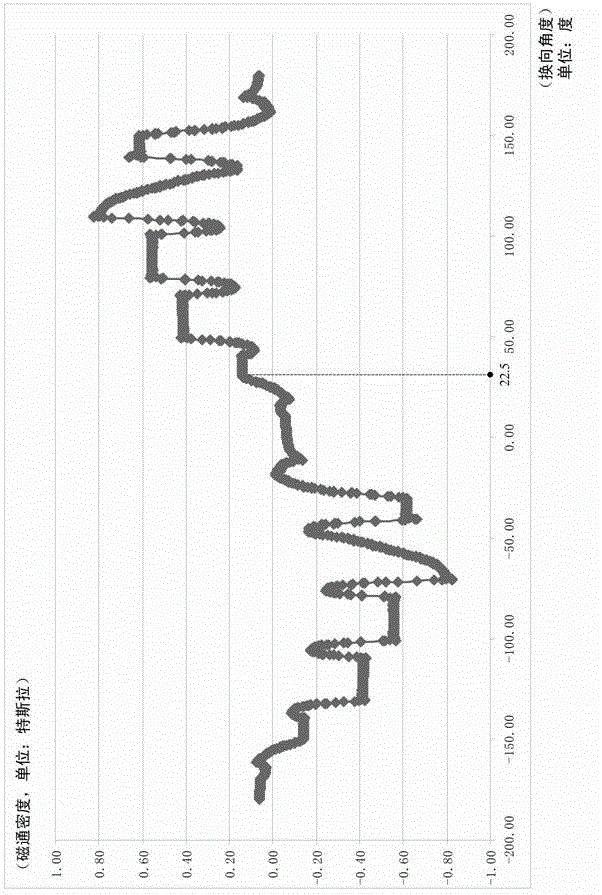

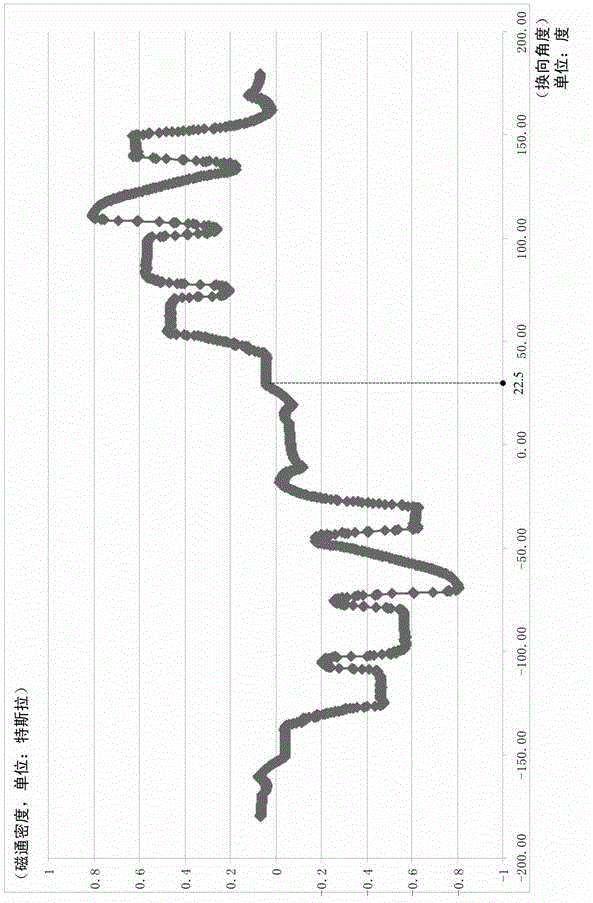

[0054] Such as Figures 6A-6B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com