Superimposed composite component

A technology of parts and overlapping surfaces, applied in vehicle parts, synthetic resin layered products, superstructure sub-assemblies, etc., can solve the problems of unstable deformation mode and uneven touch, and achieve structural changes, stable deformation methods, and structural changes. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

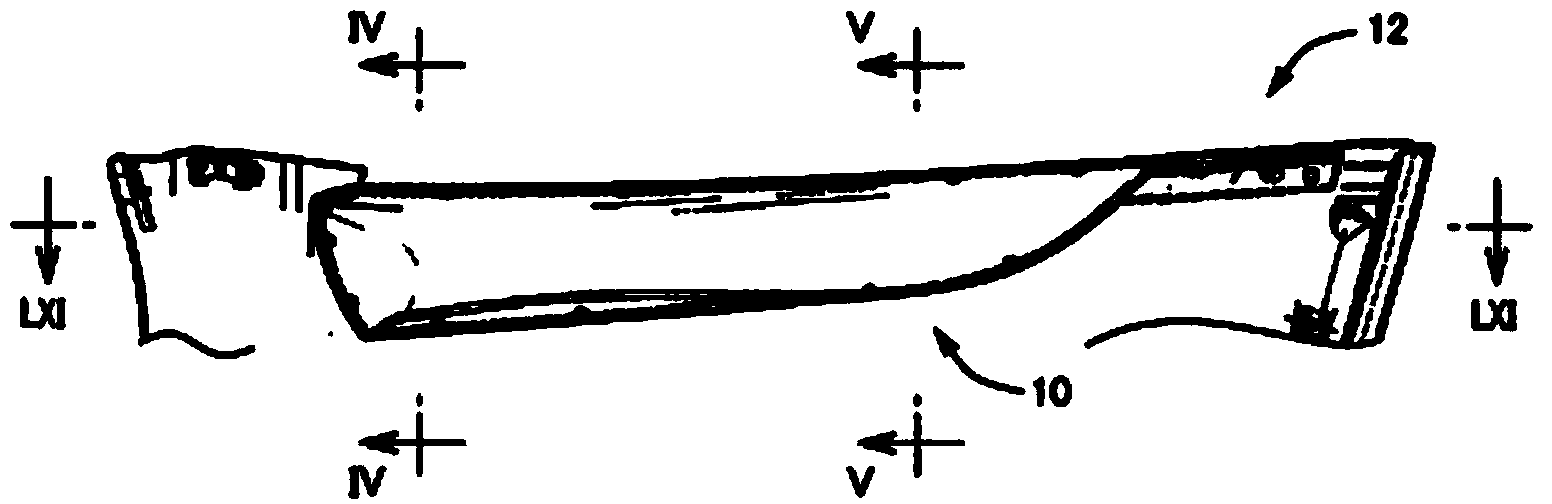

[0114] Below, while referring to the attached Figure 1 Embodiments of the present invention will be described in detail.

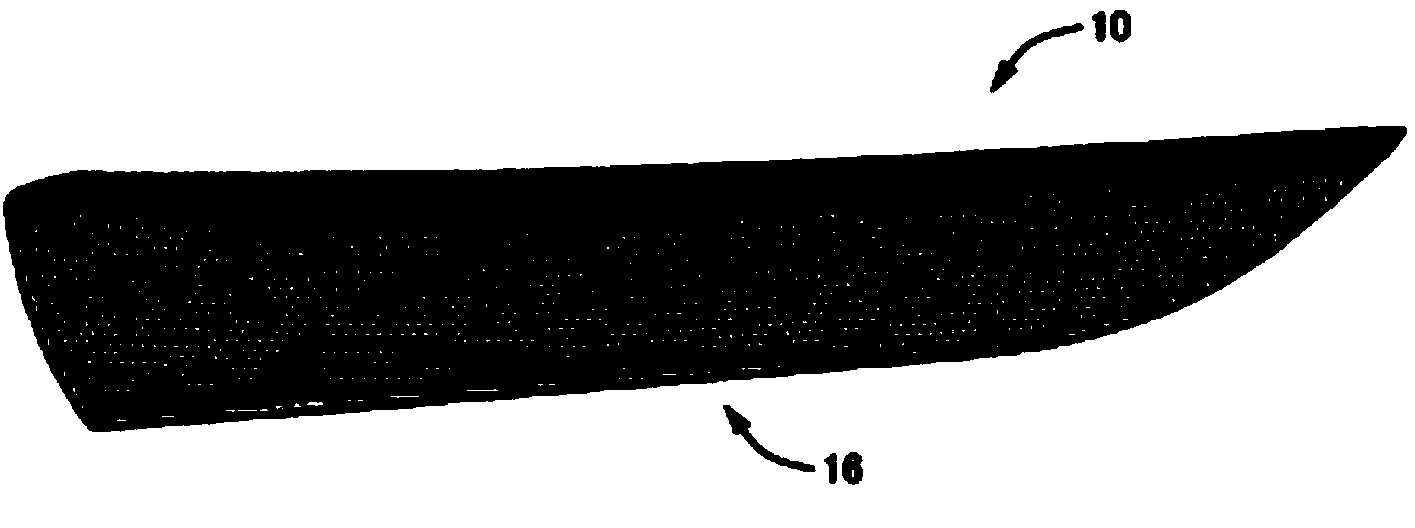

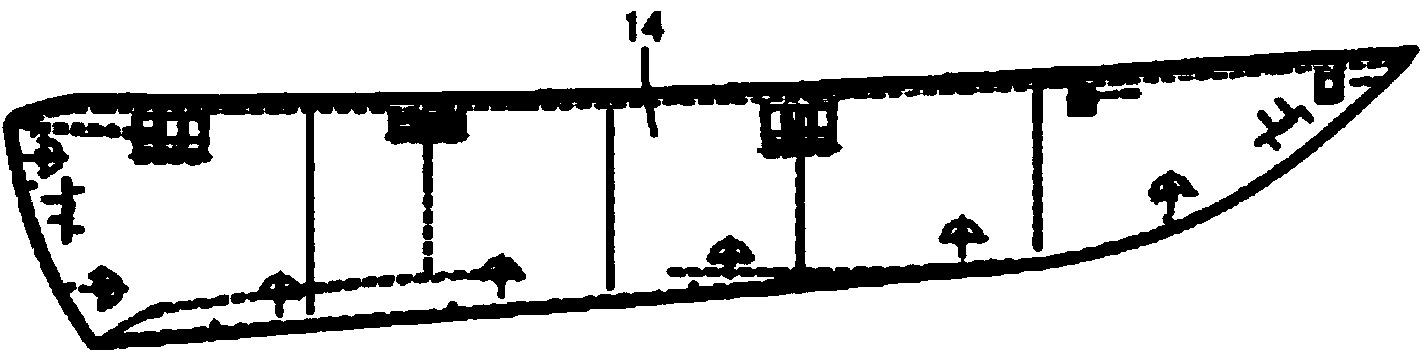

[0115] figure 1 It is a schematic diagram showing the shoulder portion (lower end portion of the window) of the upper end of the door trim 12 for a vehicle having the ornament 10 of the present invention, and is the main view seen from the design surface side of the door on the right side of the vehicle, that is, the interior side. view. figure 2 is a separate representation figure 1 The figure of the decoration 10 of the present invention shows a plurality of tiny protrusions 20 provided on the inside of the surface member 16 in perspective from the design surface side (refer to Image 6 etc.), image 3 It is a figure showing the base material 14 with the surface member 16 of the decorative article 10 removed. in addition, Figure 4 With figure 1 A cross-sectional view of an ornament 10 corresponding to the portion viewed from the arrow IV-IV in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com