Self-suspending proppants for hydraulic fracturing

A hydraulic fracturing and proppant technology, applied in the direction of drilling composition, production fluid, wellbore/well components, etc., can solve difficult proppant delivery, affect the rheological properties of the transported slurry, and interfere with the proppant mixture Uniformity setting etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

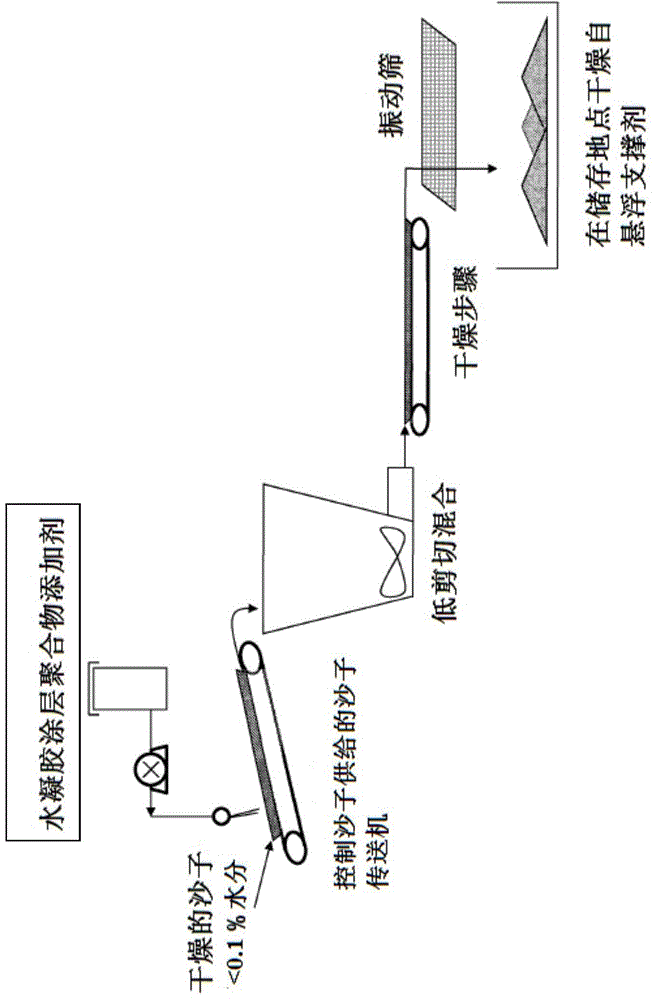

Method used

Image

Examples

Embodiment 1

[0115] Example 1: Preparation of inner polymer layer

[0116] An inner polymer layer at a concentration of 100 ppm was prepared on a sand sample by adding 200 g of 30 / 70 mesh frac sand to a FlackTek Max 100 long tank; 85 g of tap water and 2 g of 1% polydiallyl were added to the sand Dimethylammonium chloride (PDAC) solution; samples were then manually shaken for approximately 5 minutes, vacuum filtered, and dried in an oven at 80°C, after which sand samples were removed from the oven and used for subsequent testing.

[0117] The 10 ppm inner polymer layer coating was formulated using the same method as described above, except that 0.2 g of a 1% PDAC solution was used.

[0118] At maximum polymer loading ("max PDAC"), the inner polymer layer was formulated using the same method as described above, except that 1 g of a 20% by weight PDAC solution was used, and after treatment, the sand was washed with excess tap water , vacuum filtered, and dried in an oven at 80°C, after wh...

Embodiment 2

[0119] Example 2: Preparation of inner polymer layer

[0120] A 100 ppm inner polymer layer was prepared on sand samples by dissolving 0.2 g of LPEI 500 in 10 g of ethanol to form a 2% ethanol solution of LPEI 500; Added to 70 g of ethanol; then 150 g of 30 / 70 mesh frac sand was added to a round bottom flask, the solvent was removed using a rotary evaporator with a 65°C water bath, and samples were then removed from the flask and used for subsequent testing.

Embodiment 3

[0121] Example 3: Preparation of Outer Polymer Layer

[0122] The outer polymer layer was coated on sand samples by mixing the sand with liquid Flopam EM533 polymer under different conditions. In one coating method, the pure polymer product is added, and in the other coating method, the polymer product is extended by dilution with hexane. For hexane dilution, in a 40 mL glass vial, add 10 g of polymer to 10 g of hexane and vortex until homogeneous. The polymer was then added to a 30 g sample of 30 / 70 mesh frac sand in a FlackTek Max 100 tank. The samples were placed in a FlackTek DAC 150 SpeedMixer at 2600 rpm for approximately 25 seconds. The samples were removed from the SpeedMixer and dried in an oven at 80°C overnight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com