Novel spring mattress

A mattress, a new type of technology, applied in the direction of spring mattresses, mattresses, stuffed mattresses, etc., can solve the problems of large spring mattress thickness, incomplete arrangement of human bone mechanics, short service life, etc., to improve the overall Excellent support and elasticity, protection of spine health, and excellent decompression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

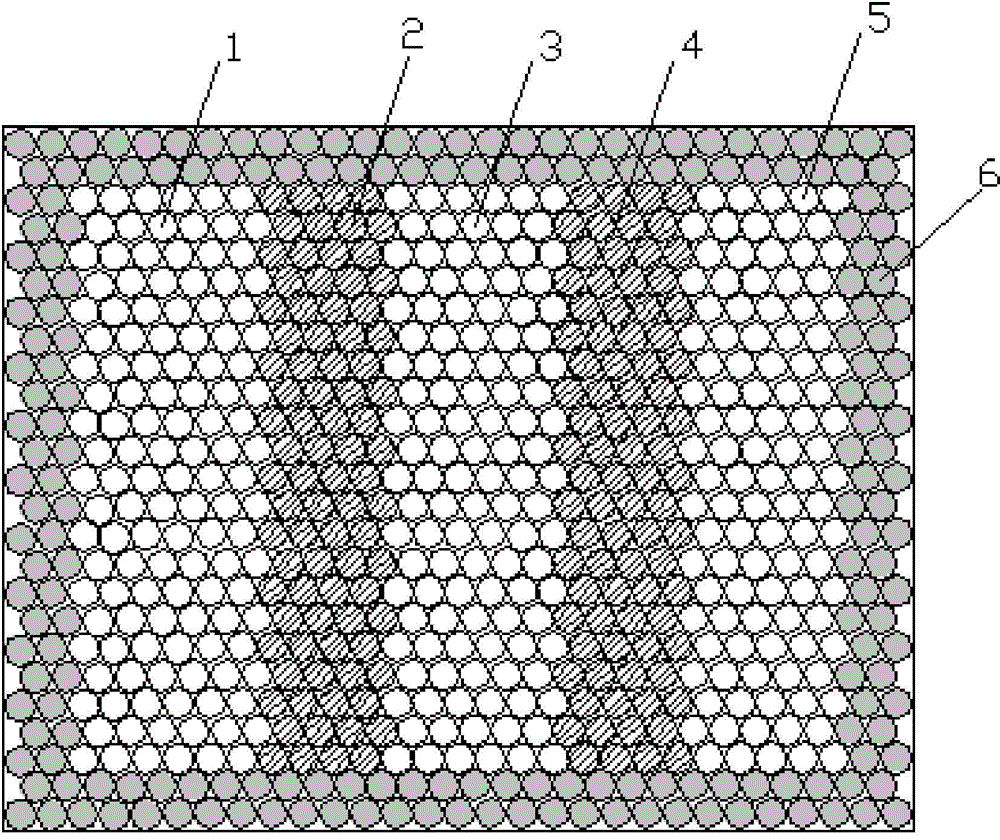

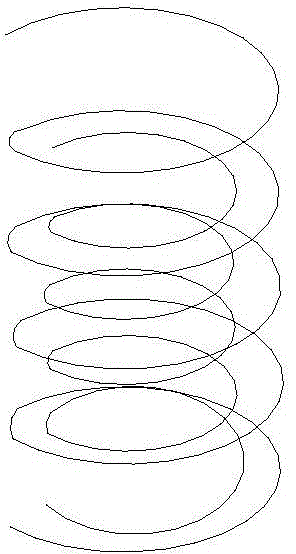

[0029] refer to figure 1 As shown, the present invention provides a novel spring mattress, including a spring area and an edge reinforcement layer, and the spring area includes a first spring area, a second spring area, a third spring area, a fourth spring area, and a fifth spring area. area, the spring hardness of the first spring area, the third spring area and the fifth spring area is lower than the spring hardness of the second spring area and the fourth spring area, and the edge reinforcement layer is arranged in the spring area The four sides of the mattress include 2-3 rows of hardened springs. The hardness of the hardened springs is higher than that of the second spring area and the fourth spring area. The mattress with partition design can support the bone curve of the human body.

[0030] Preferably, the springs in the spring area and the edge reinforcement layer are arranged in a honeycomb shape.

[0031] The springs of the first spring area, the second spring area...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that the steel wire diameter of the springs in the first spring area, the third spring area and the fifth spring area is 1.0mm, and the second spring area and the fourth spring area The steel wire diameter of the spring in the area is 1.1mm, and the steel wire diameter of the spring in the edge reinforcement layer is 1.3mm.

Embodiment 3

[0038] The difference between this embodiment and Embodiment 1 is that the steel wire diameter of the springs in the first spring area, the third spring area and the fifth spring area is 0.9mm, and the second spring area and the fourth spring area The steel wire diameter of the spring in the area is 1.0 mm, and the steel wire diameter of the spring in the edge reinforcement layer is 1.1 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com