Rolling method for preventing deviation of hot-rolled steel strip with thickness not greater than 4mm

A hot-rolled strip and deviation technology, applied in the direction of metal rolling, temperature control, metal rolling, etc., can solve the problems of cumbersome operation, achieve the effect of simple operation, reduce steel piles, and reduce accident handling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The target material is 50 steel, and the product specification is 3.5mm×1250mm. According to the rolling plan arrangement, 4 pieces of transition material are arranged in a centralized manner, and Q345B steel with the same strength level is selected. The product specification is 4.5mm×1250mm and 4.0mm×1250mm as the transition material. Roll 2 pieces in sequence.

[0024] Continuous casting slab size 230mm×1250mm, heating temperature control: preheating period 40min, heating period 80min, soaking period 60min, total time in furnace 180min, furnace temperature 1230℃.

[0025] Rough rolling process control: rapid rolling under high pressure is adopted, the exit temperature of rough rolling is controlled at 1070°C, and the thickness of the slab after rough rolling is 36mm.

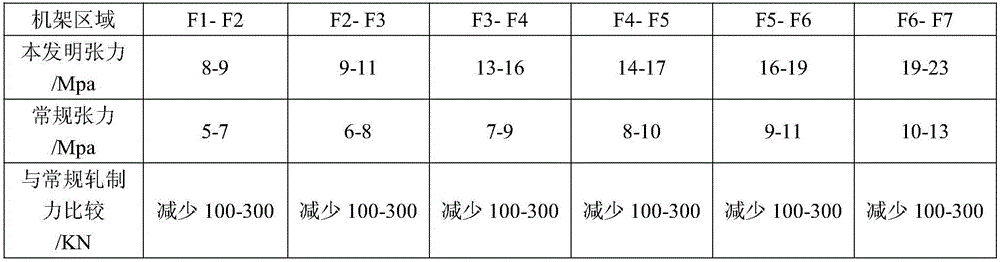

[0026] Finish rolling process control: strip crown is controlled at 60μm, wedge shape is controlled at ≤20μm, the start and finish rolling temperature is 1060°C, and the finish rolling temperature is co...

Embodiment 2

[0034] The target material is SPHC steel, and the product specification is 2.0mm×1250mm. According to the rolling plan arrangement, 6 pieces of transition material are arranged in a centralized manner, and Q235B steel with the same strength level is selected. The products are 3 pieces in the order of 2.5mm×1250mm and 2.3mm×1250mm. Rolled as transition material.

[0035] The size of the continuous casting slab is 230mm×1250mm, and the heating temperature is controlled: the preheating period is 50min, the heating period is 90min, the soaking period is 50min, the total time in the furnace is 190min, and the furnace temperature is 1243°C.

[0036] Rough rolling process control: rapid rolling under high pressure is adopted, the exit temperature of rough rolling is controlled at 1090°C, and the thickness of the slab after rough rolling is 36mm.

[0037] Finish rolling process control: strip crown is controlled at 40μm, wedge shape is controlled at ≤20μm, the start and finish rolling...

Embodiment 3

[0045] The target material is Q235B steel, and the product specification is 1.5mm×1250mm. According to the rolling plan arrangement, 8 pieces of transition material are arranged in a centralized manner, and SPHC steel with the same strength level is selected. The products are 4 pieces in the order of 2.0mm×1250mm and 1.8mm×1250mm. Rolled as transition material.

[0046] The size of the continuous casting slab is 230mm×1250mm, and the heating temperature is controlled: the preheating period is 49 minutes, the heating period is 91 minutes, the soaking period is 55 minutes, the total time in the furnace is 195 minutes, and the furnace temperature is 1245°C.

[0047] Rough rolling process control: rapid rolling under high pressure is adopted to prevent the temperature drop of the slab. In order to ensure the temperature, descaling is appropriately reduced. The exit temperature of the rough rolling is controlled at 1095°C, and the thickness of the slab after rough rolling is 36mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com