An optimal scheduling method for a printed circuit board surface mount production line

A printed circuit board and surface mount technology, applied in the field of intelligent optimization and scheduling of production workshops, can solve the problems of low economic efficiency, customer dissatisfaction, waste of processing and sorting factory costs, etc., to reduce production costs, realize the placement process, and improve the The effect of loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

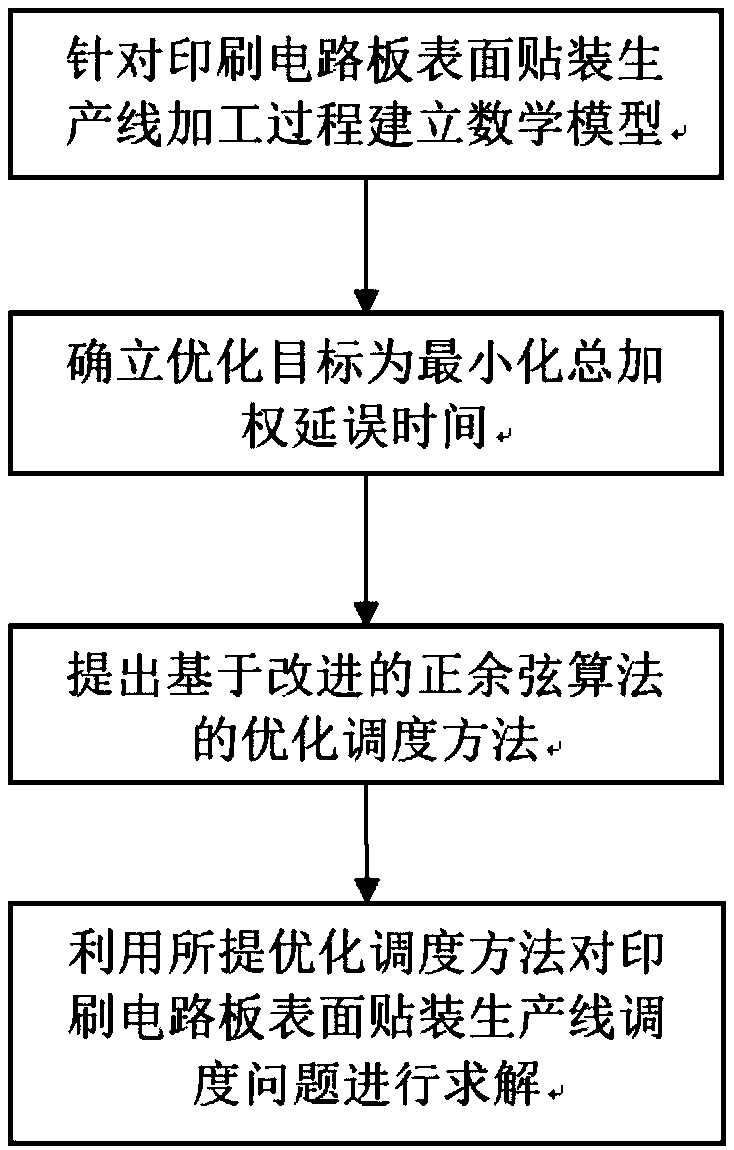

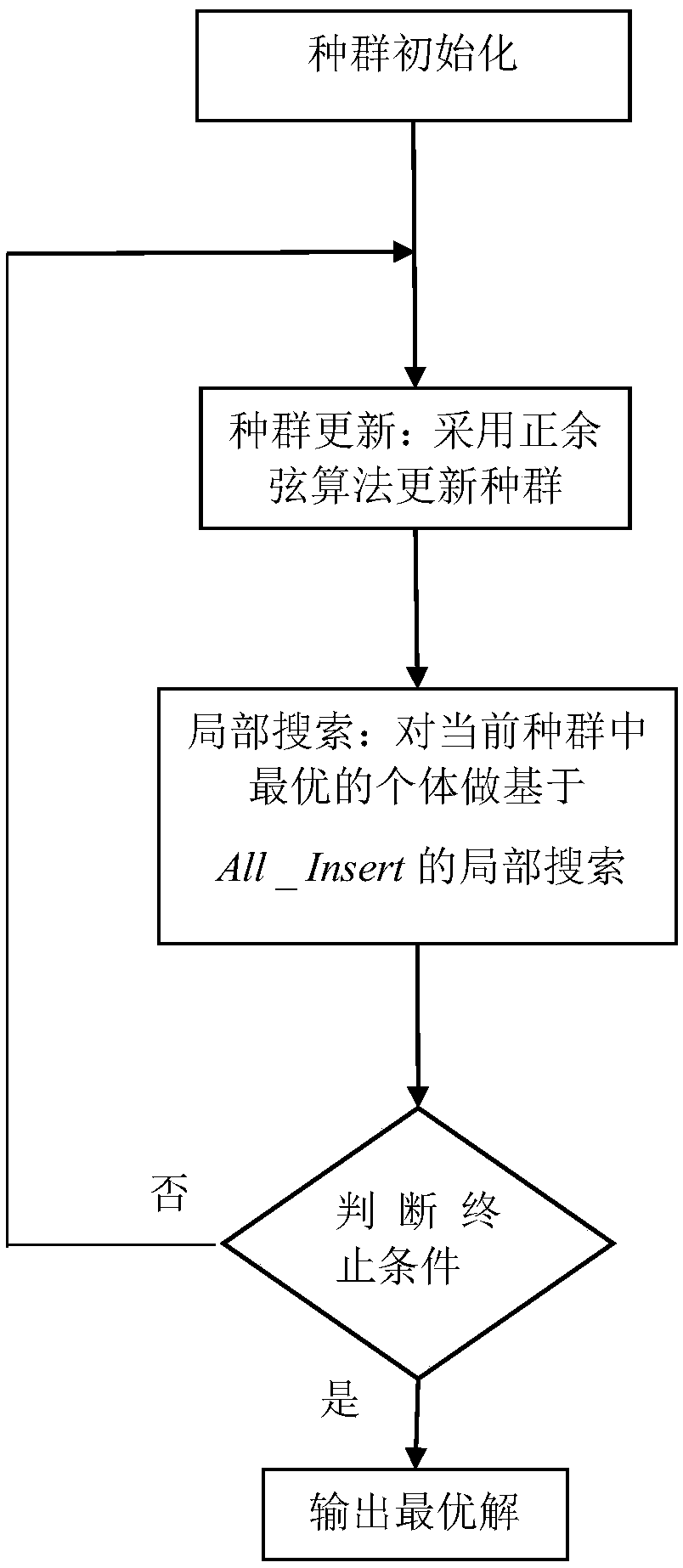

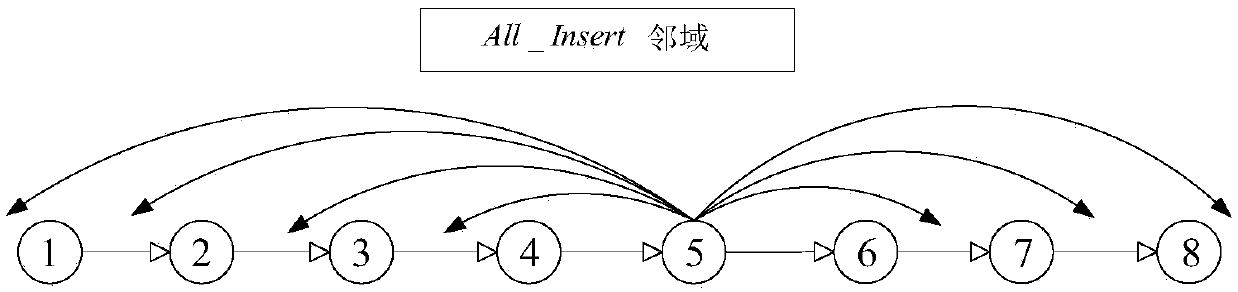

[0026] Example 1: Such as Figure 1-3 As shown, an optimized scheduling method for a printed circuit board surface mount production line is used to establish a disjunctive planning model and determine an optimization goal through the scheduling process of a printed circuit board surface mount production line, and use an optimized scheduling method based on an improved sin-cosine algorithm to The goal is optimized; the printed circuit board surface mount production line scheduling problem is represented by the disjunctive graph G=(N,A,E,Re), and the disjunctive planning model is based on the number of processes and processing time of each PCB on each placement machine And the processing order constraints of each PCB on each placement machine are established in the description of the disjunctive diagram, and the optimization goal is the total weighted delay time; the disjunctive programming model is described as follows:

[0027]

[0028]

[0029]

[0030]

[0031]

[0032]

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com