Gating system for U-shaped screw pressurization diffuser casting

A technology of screw pressurization and pouring system, which is applied in the direction of molds, cores, mold components, etc., can solve the problems of high production cost and low product qualification rate, so as to avoid shrinkage cavity, weaken direct impact, prevent damage and overheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

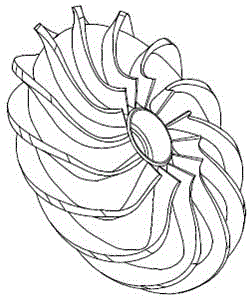

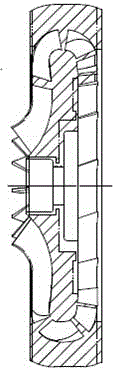

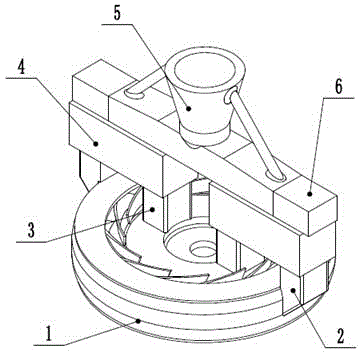

[0023] A gating system for U-shaped spiral booster diffuser castings, the gating system is arranged on the upper part of the diffuser wax 1, the structure of the gating system can be found in Figure 3-Figure 5 , which includes a side pouring riser 2, a direct pouring riser 3, a main runner 4, a sprue cup 5 and a flat die head 6. There are two side pouring risers 2, direct pouring risers 3 and flat die heads 6, and two main runners 4 are provided. The center lines of the two side pouring risers, the two direct pouring risers, the two main runners 4 and the two flat die heads 6 are located in the same vertical plane as the radial direction of the diffuser wax piece 1 .

[0024] The two side pouring risers are radially symmetrically arranged on the outer edge of the diffuser wax; the two direct pouring risers are radially symmetrically arranged on the large plane of the diffuser wax, and the center connection line of the two side pouring risers and the two The center line of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com