Three-layer gas protection cover for titanium and titanium alloy friction stir welding

A technology of friction stir welding and titanium alloy, which is applied in the direction of welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of small area protected by welding, lack of gas protection of formed weld seam, performance degradation, etc., to achieve good Protecting effect, ensuring the quality of friction stir welding, and stabilizing the effect of gas shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

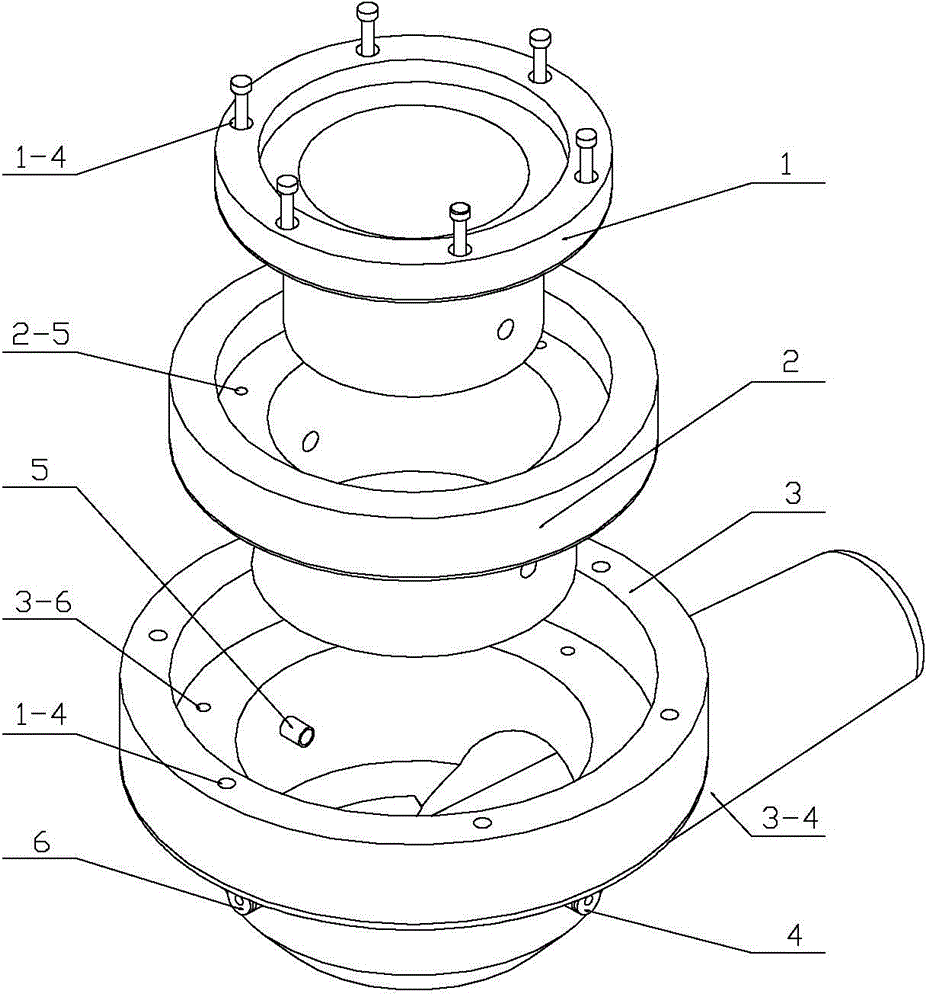

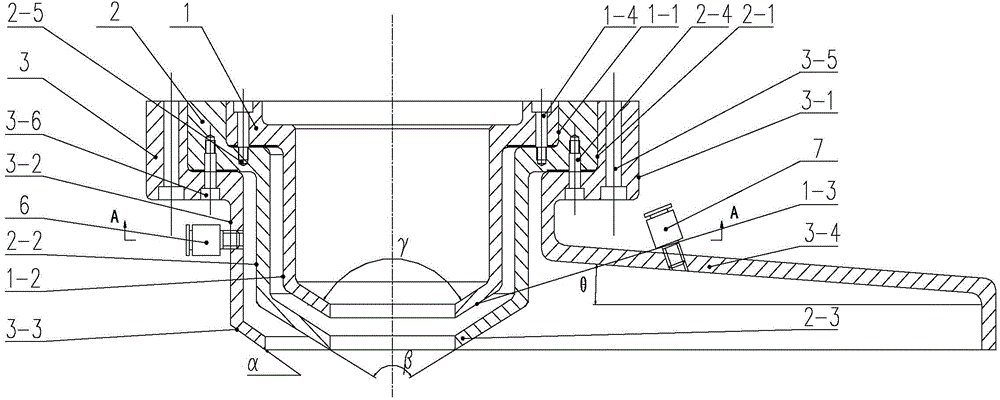

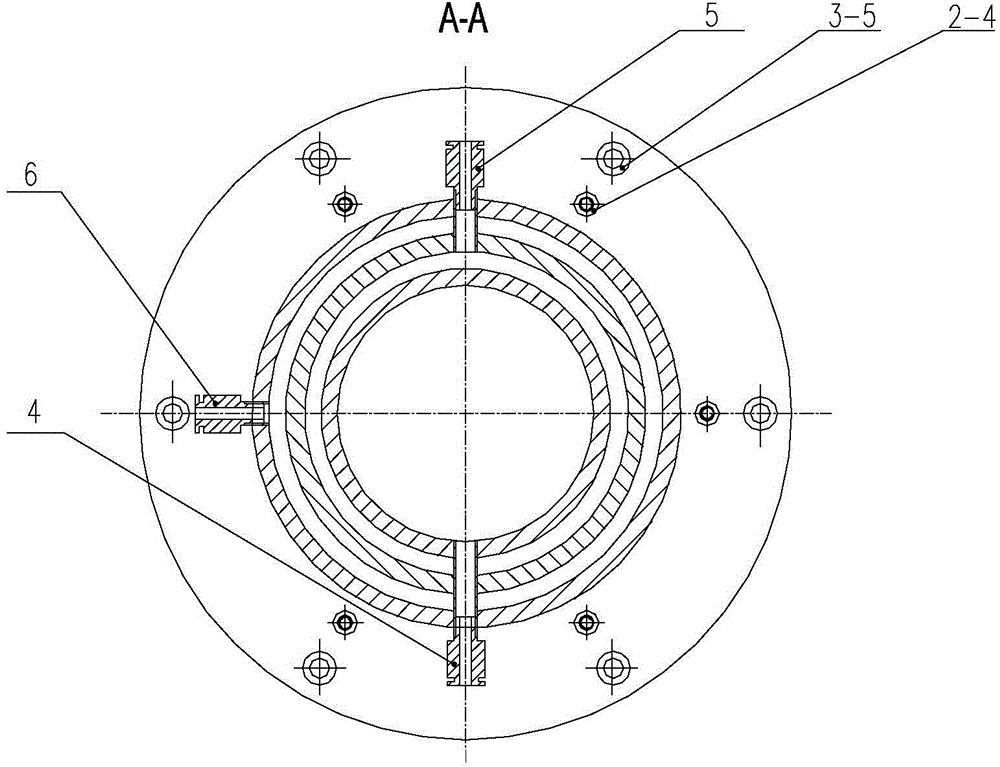

[0012] Specific implementation mode one: combine figure 1 , figure 2 and image 3 Describe this embodiment mode, a kind of titanium and titanium alloy friction stir welding of this embodiment mode three-layer gas protection cover comprises inner gas cover 1, middle layer gas cover 2, outer gas cover 3, inner gas cover inlet nozzle 4, middle layer gas cover Cover air intake nozzle 5, outer air cover cylindrical gas inlet section intake nozzle 6 and outer air cover trailing section intake nozzle 7; inner air cover 1, middle layer air cover 2 and outer air cover 3 are equipped with Through the cavity, the inner air cover 1 is installed in the cavity of the middle air cover 2, and the middle air cover 2 is installed in the cavity of the outer air cover 3,

[0013] The external shape of the inner gas hood 1 is composed of a cylindrical fitting section 1-1, a cylindrical gas inlet section 1-2 of the inner gas hood, and a frustum-shaped gas outflow section 1-3 of the inner gas hoo...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 , figure 2 and image 3 Describe this embodiment, the inner air cover 1 of this embodiment, the middle layer air cover 2, the outer air cover 3, the inner air cover intake nozzle 4, the middle layer air cover intake nozzle 5, the outer air cover cylindrical gas inlet section intake Mouth 6 and outer air cover trailing section inlet nozzle 7 are all made of stainless steel. This is set up to ensure a smooth surface and dimensional stability during long-term work. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 2 To illustrate this embodiment, the air inlet nozzle 4 of the inner gas hood in this embodiment is 1-2mm away from the inner wall of the cylindrical gas inlet section 1-2 of the inner gas hood. It is set in this way to ensure that gas flows into the inner gas hood 1 reliably. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com