Process for producing cover glass for potable appliance

A technology for protective glass and portable equipment, applied in the field of protective glass for portable equipment, can solve the problems of increased Li ion concentration, difficult ion exchange, etc., and achieves the effect of small intensity unevenness and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

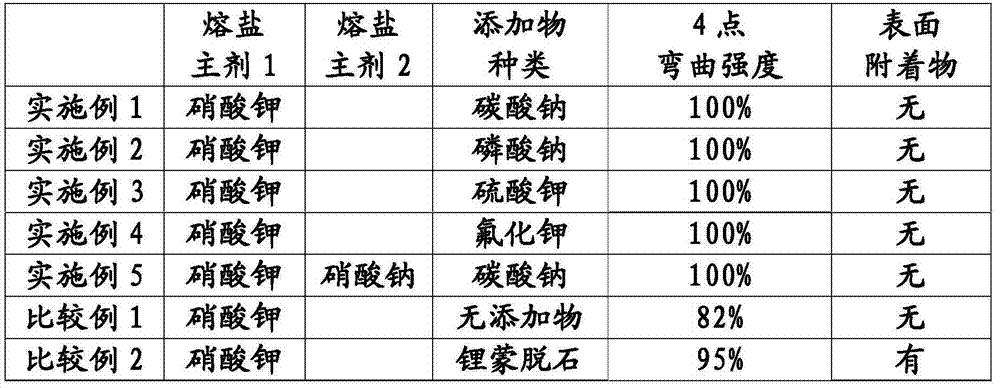

Embodiment 1)

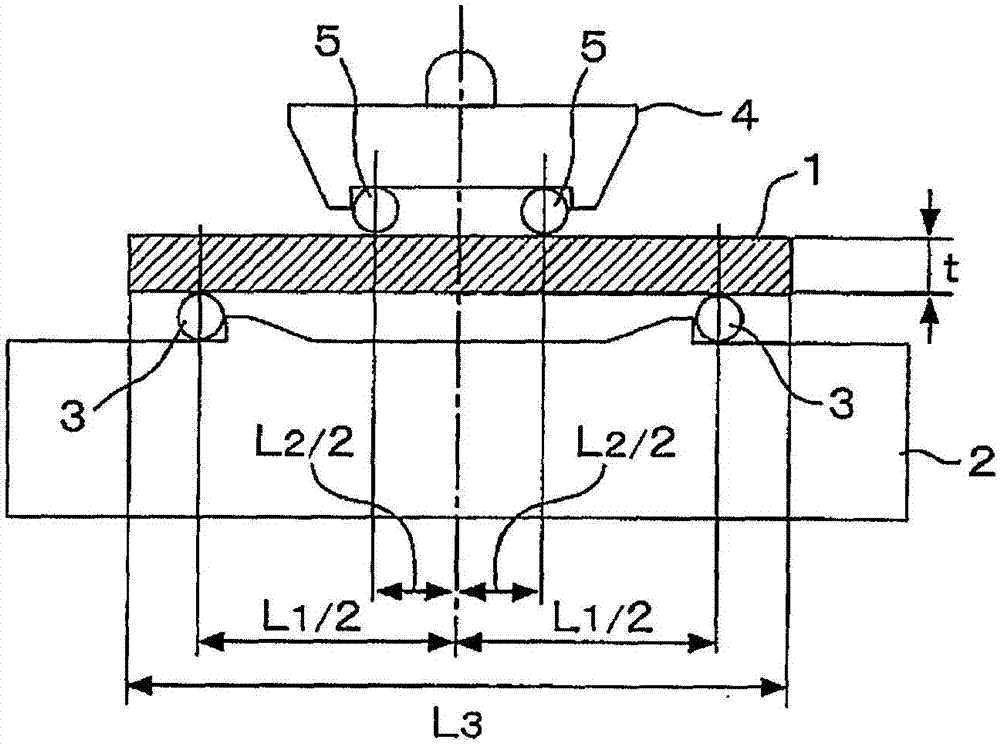

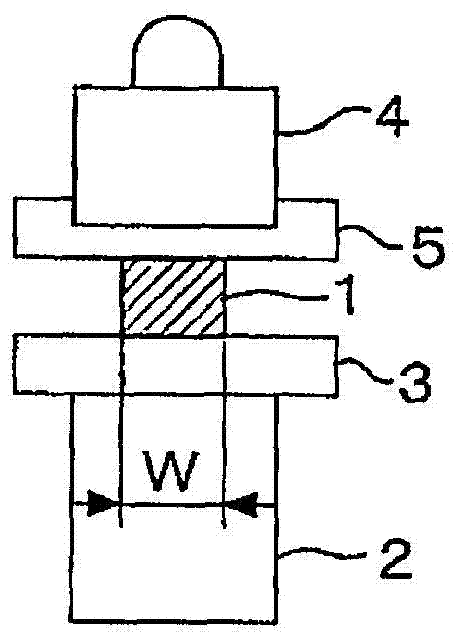

[0093] The cover glass for portable devices of this Example was manufactured through the following (1) glass plate cutting process process, (2) chemical strengthening process.

[0094] (1) Glass plate cutting process

[0095] First, a large-sized glass plate with a thickness of 0.5 mm made of aluminosilicate glass produced by the down-draw method or float method is cut to form a cover glass (substrate for cover glass) of a predetermined size (long side 10 cm x short side 5 cm). ). As this aluminosilicate glass, a glass containing SiO 2 : 58 to 75% by weight, Al 2 o 3 : 5 to 23% by weight, Li 2 O: 3 to 10% by weight, Na 2 O: 4 to 13% by weight, ZrO 2 : 5.5 to 15% by weight of glass for chemical strengthening. The cutting of this glass plate is performed by machining.

[0096] (2) Chemical strengthening process

[0097] Next, chemical strengthening is given to the said cover glass. Chemical fortification using potassium nitrate (KNO 3 ) as molten salt, and prepare to ...

Embodiment 2)

[0110] In the chemical strengthening process of Example 1, sodium phosphate (Na 3 PO 4 ) was used as an additive to be added to the molten salt solution, and a chemical strengthening process was implemented in the same manner as in Example 1 to manufacture cover glasses for portable devices (100 sheets).

Embodiment 3)

[0112] In the chemical strengthening process of Example 1, potassium sulfate (K 2 SO 4 ) was used as an additive to be added to the molten salt solution, and a chemical strengthening process was implemented in the same manner as in Example 1 to manufacture cover glasses for portable devices (100 sheets).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com